To my other GT6

pages.

November 11, 2020

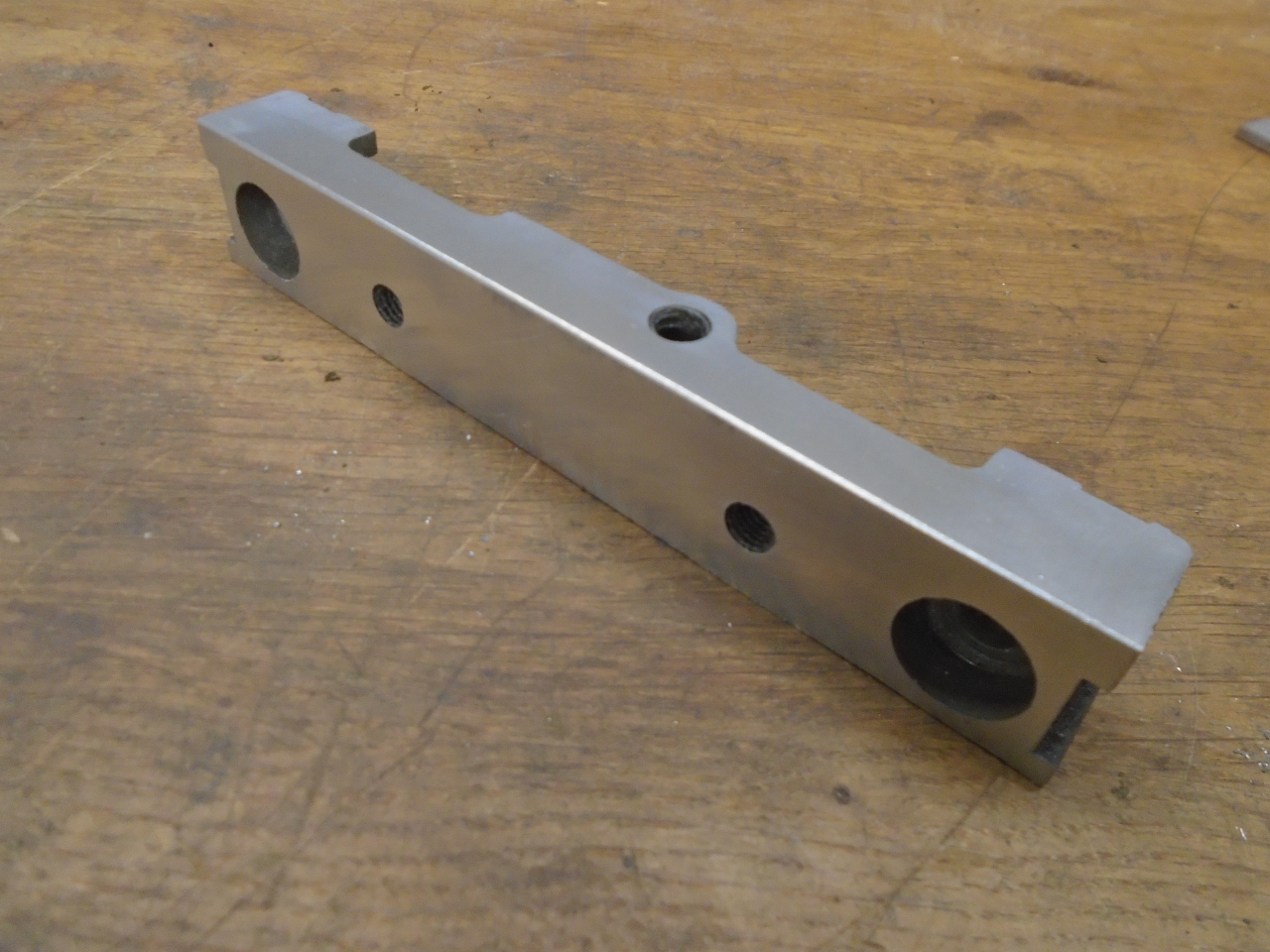

Front Sealing Block

The Triumph straight six engines have a gap in the crank case

perimeter at both the front and rear where the main bearings were

installed. The approximately six-inch gap at the front is

bridged by the Front Sealing Block. This is a chunk of cast

zinc alloy that both the oil pan and the front engine plate bolt

to.

It isn't really a bad design, but it has a few quirks that bear

some attention.

Normally, the main issue is that in the soft material, the

shallow-ish fine thread tapped holes can be prone to stripping,

especially with repeated disassembly or overenthusiastic

torquing. For this reason, fortifying the threaded holes is

pretty common, either as a repair, or a preventative measure.

My tapped holes

were not stripped, but I decided to upgrade my original block by

strengthening the threads. I know that aftermarket

blocks are easily available in aluminum or steel, but though these

might be totally reasonable way to go, that's not the way I

roll.

But before I considered the holes, I wanted to clean up the

block. I quickly discovered that the oil pan sealing surface

wasn't flat.

This wasn't surprising, since I found the same thing on the

TR6. So I machined the surface flat by removing around

0.015" from the high areas. The block could accommodate this

since it stood slightly proud of the crank case pan surface

anyway. I did the same to the front surface, but only had to

take off a few thousandths.

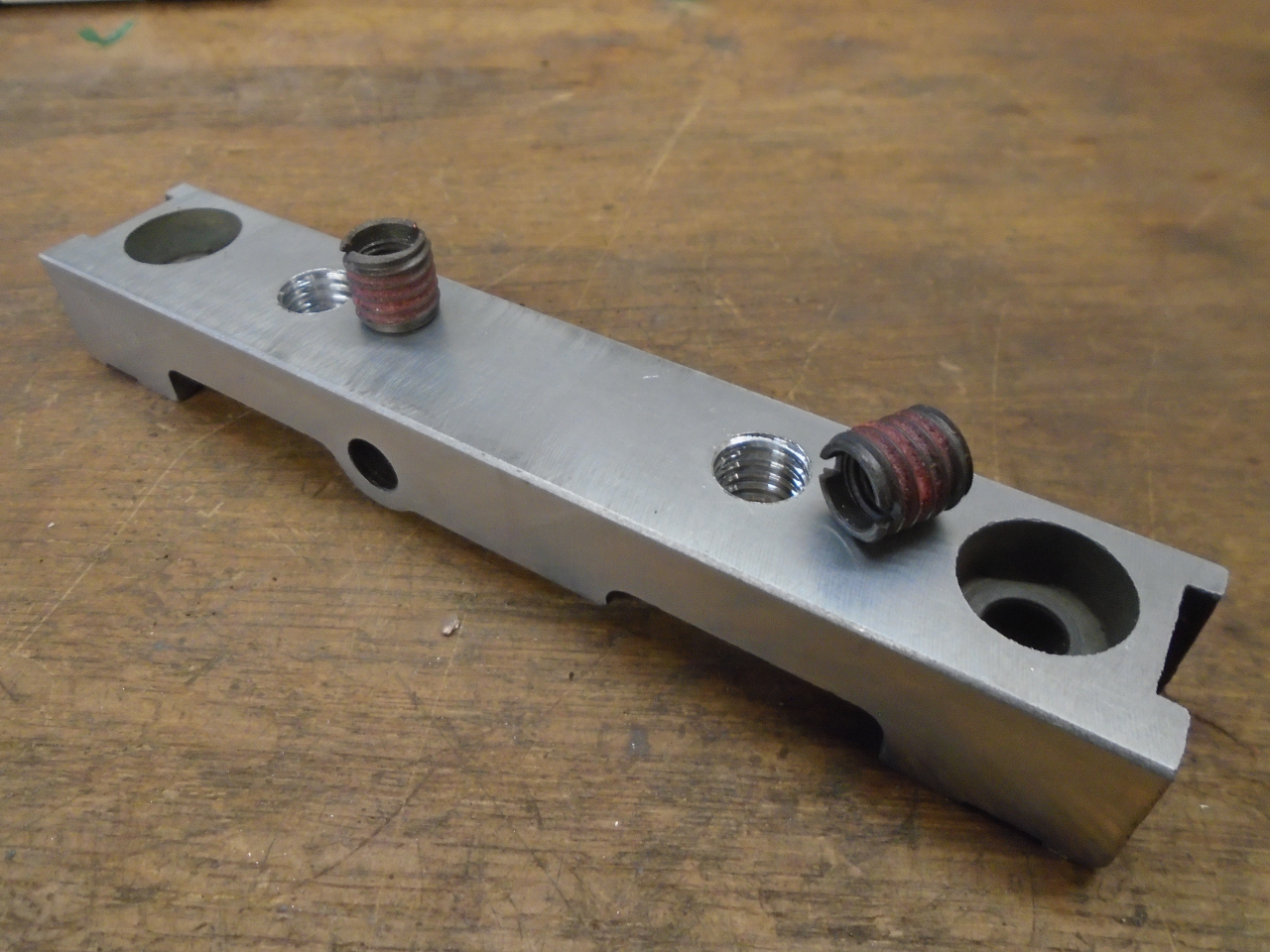

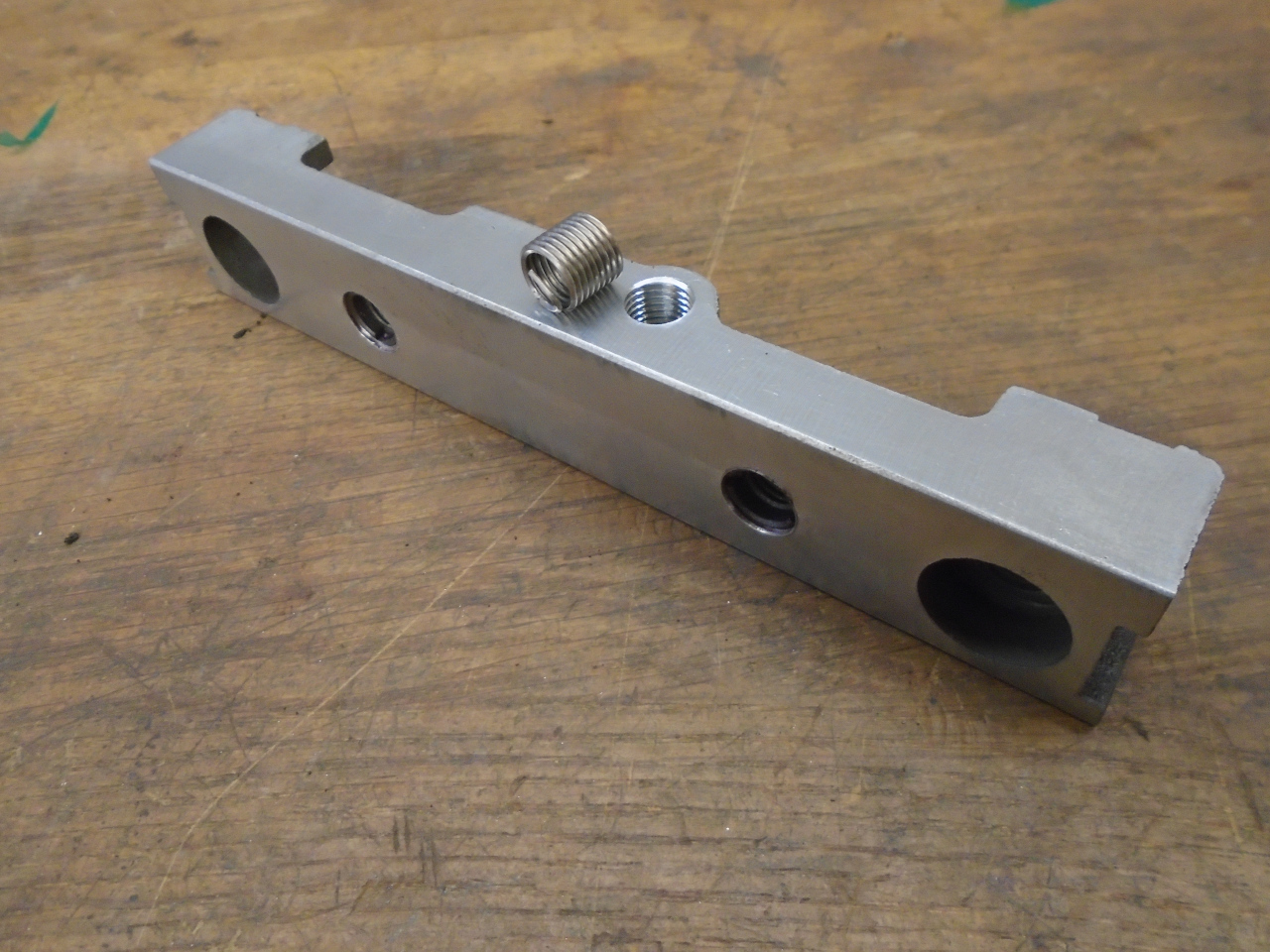

My thread-enhancer of choice is usually an insert, because they

use standard taps. These are EZ-LOKs, but there are other

brands. These allegedly come with a permanent thread locker

on the OD, but I usually add some of my own.

However, on the front face of the block, the single tapped hole

didn't seem to me to have enough meat around it for an insert, so

I opted for a coil-type repair, since they take a smaller hole.

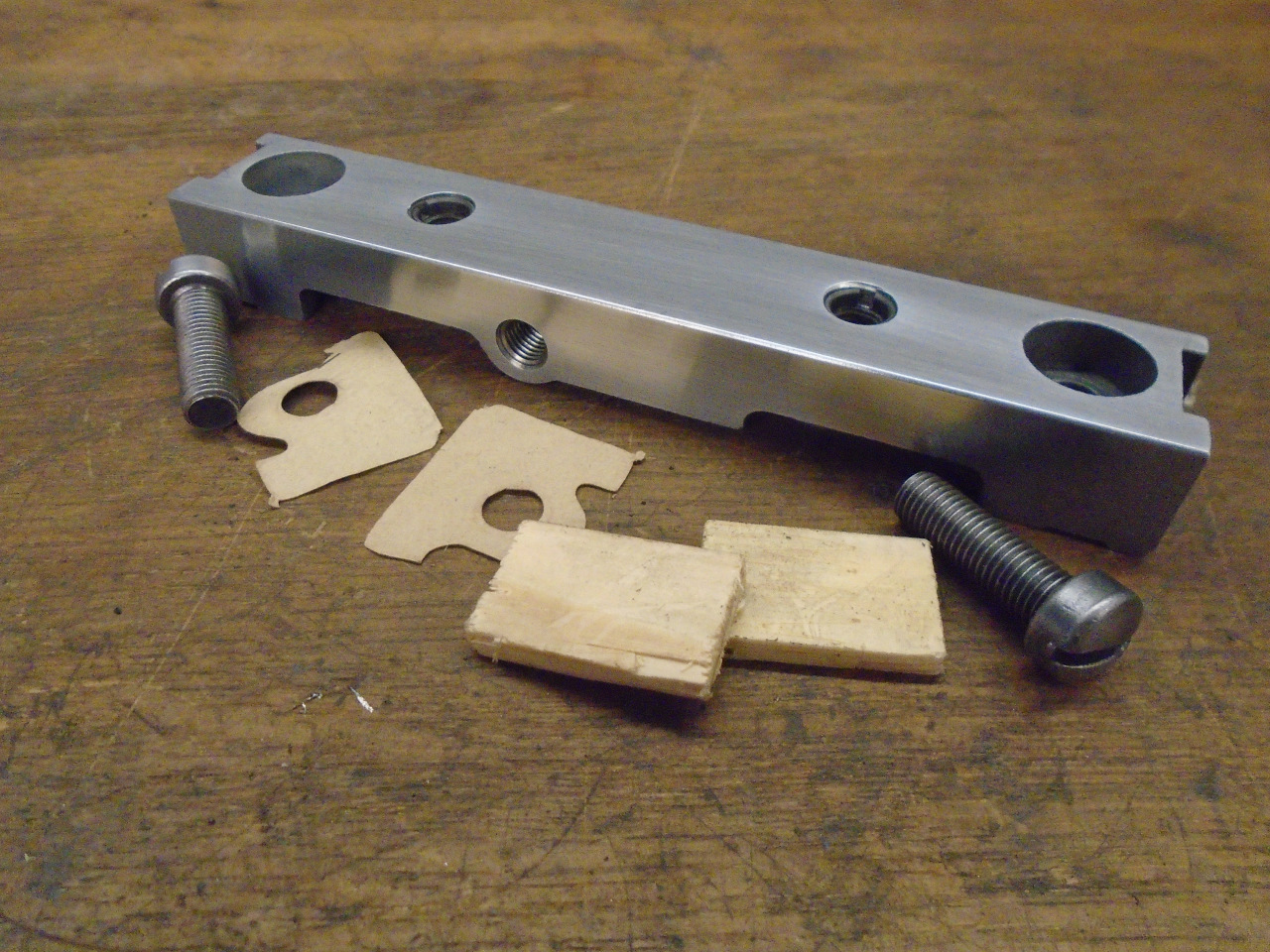

With those fixes done, I dug out the appropriate items from the

lower end gasket set I bought. Here is where I recalled the

quaint method that Triumph engineers specified to seal the ends of

the block to the crank case. They used little shards of wood

compressed into shallow slots on each end. I believe some

rebuilders may substitute a rubber block for the wood, but I

actually don't think there is anything wrong with wood. It

may be a throw-back approach, but wood is a compressible material

that will last a long time in this environment, and if the grain

is oriented properly, it will not wick oil.

However, I was a little disappointed with the wood chips

supplied. They were very rough cut, and quite oversized in

all dimensions. Also I could see that they were cut from

finger-joined material, and I didn't know how the glue would stand

up to hot oil exposure. Rather than mess with those pieces,

I decided to just curt my own. In a bit of serendipity, I

found that a paint stir stick was just the right thickness, so my

wood seals were made from that. They need to be sized so

that they compress in width and thickness when installed.

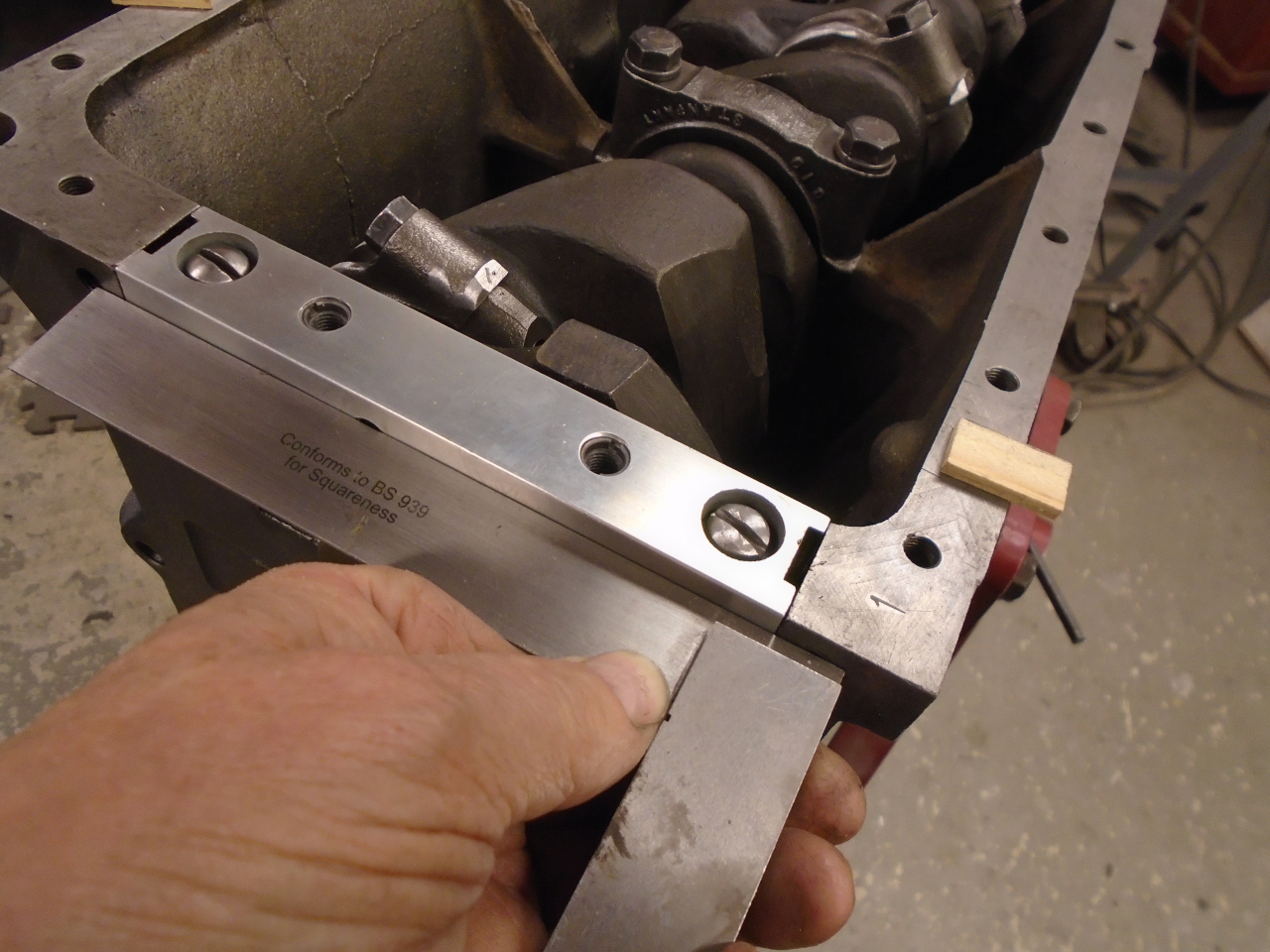

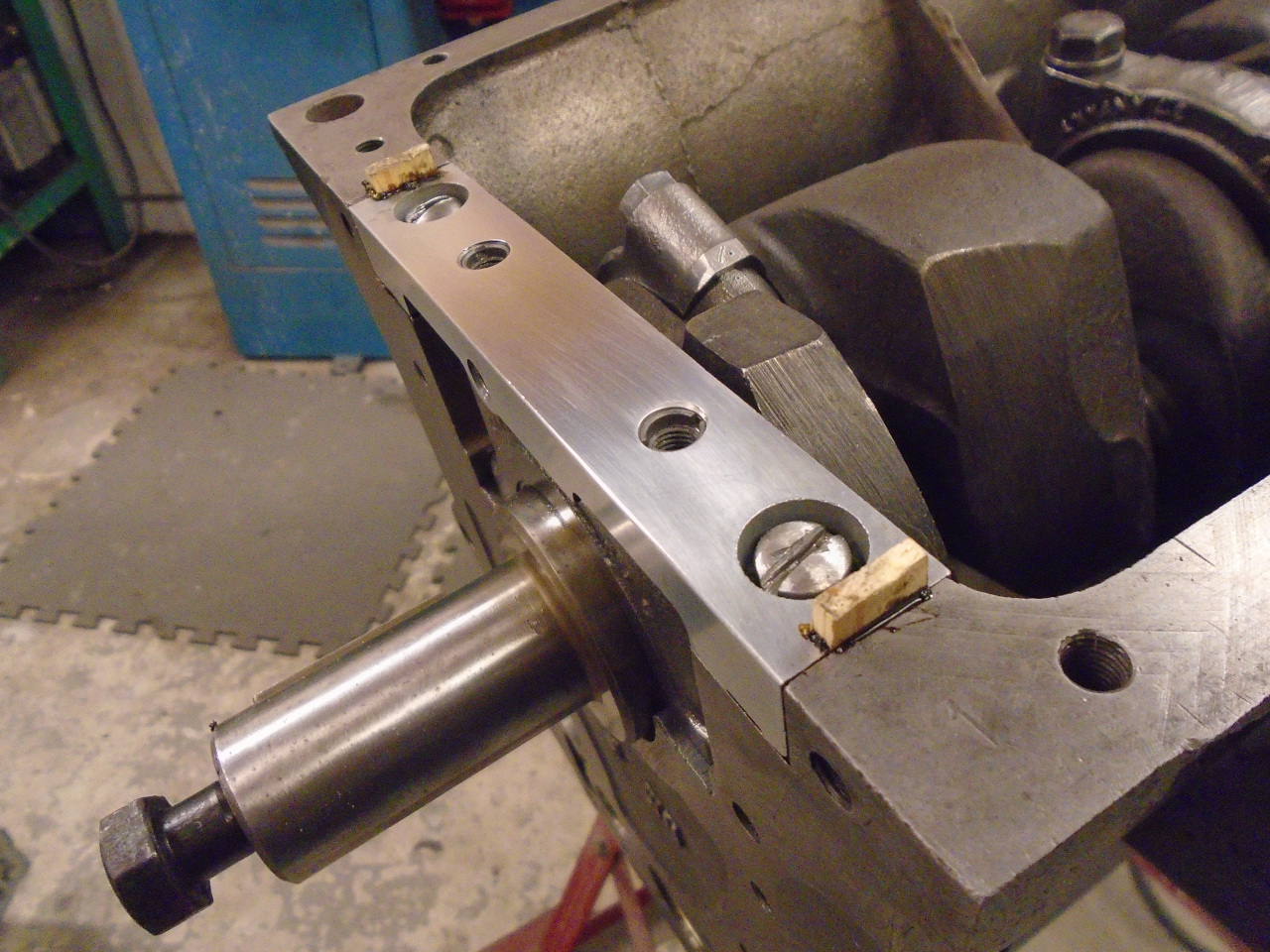

The block was lightly fastened to the crank case, checking that it

was flush at the front...

...then the wood chips got a nice thin coat of Permatex 3D, and

were tapped home.

Finally, the chips were trimmed flush, and the block torqued to

spec.

These are fun projects--quick, easy, low risk, and pretty cheap.

Comments to Ed at elhollin1@yahoo.com

To my other GT6

pages.