To my other GT6

pages.

October 31, 2020

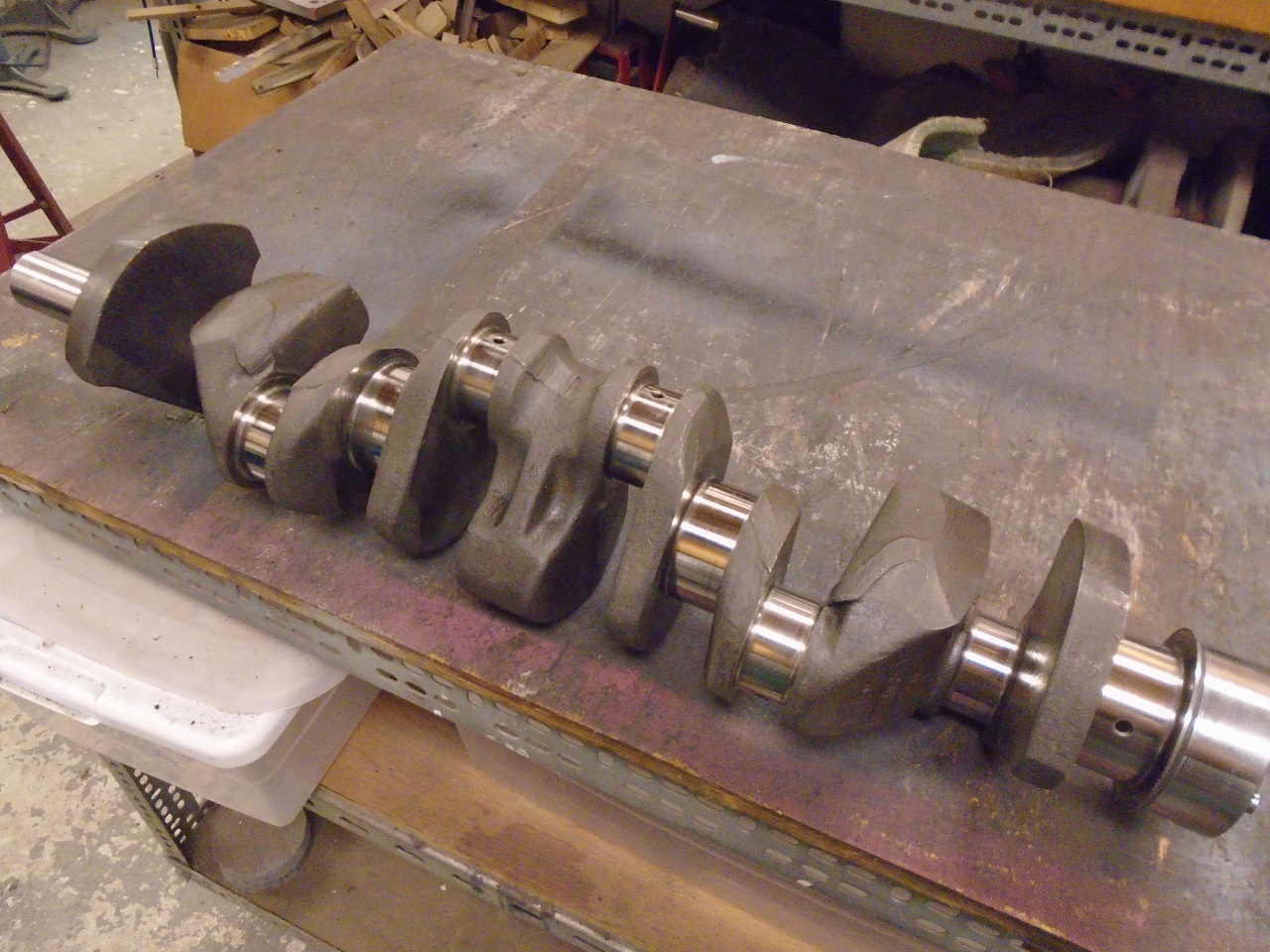

Crank, Rods, & Pistons

When I did a cursory rebuild of this engine in the early 80s, the

machine shop I took my crank to told me that is was still in spec,

so I just had the journals polished. Now, nearly 40 years,

but less than 10,000 miles later, I didn't expect much

change. As expected, the journals still looked very good,

and I measured them to still be within factory spec. This

was obviously good news. Other than general cleaning and

swabbing the oil channels, I did do some minor touch up polishing

in a few places.

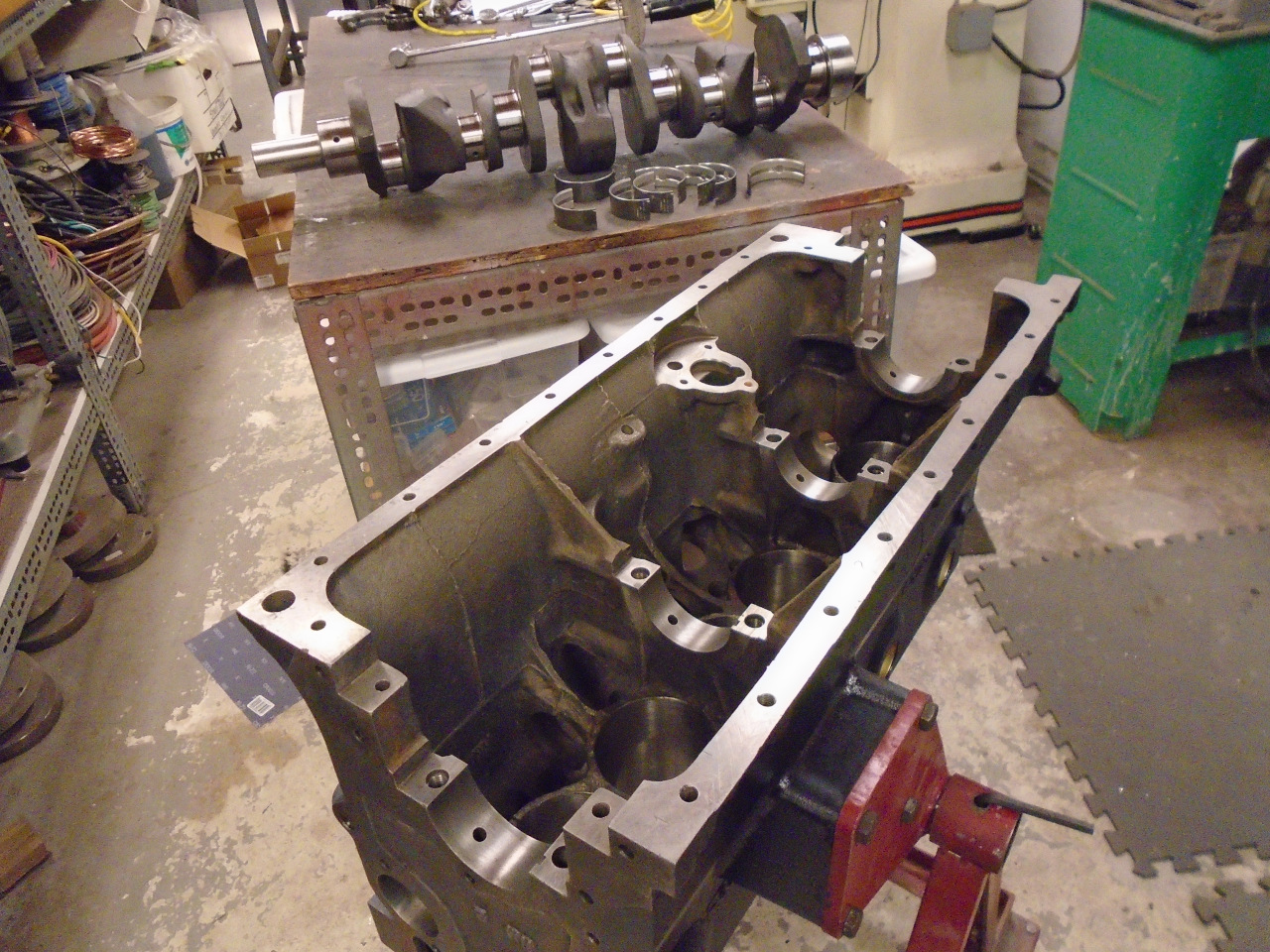

I probably could have even re-installed the main bearings, but I

mixed them up, so I just got new ones. As a double check, I

used some Plastigage to verify the clearance. It came out a

little under 0.002", which seemed OK to me.

I installed the crank with some nice assembly lube. All

torqued down, the crank was still easy to turn by hand.

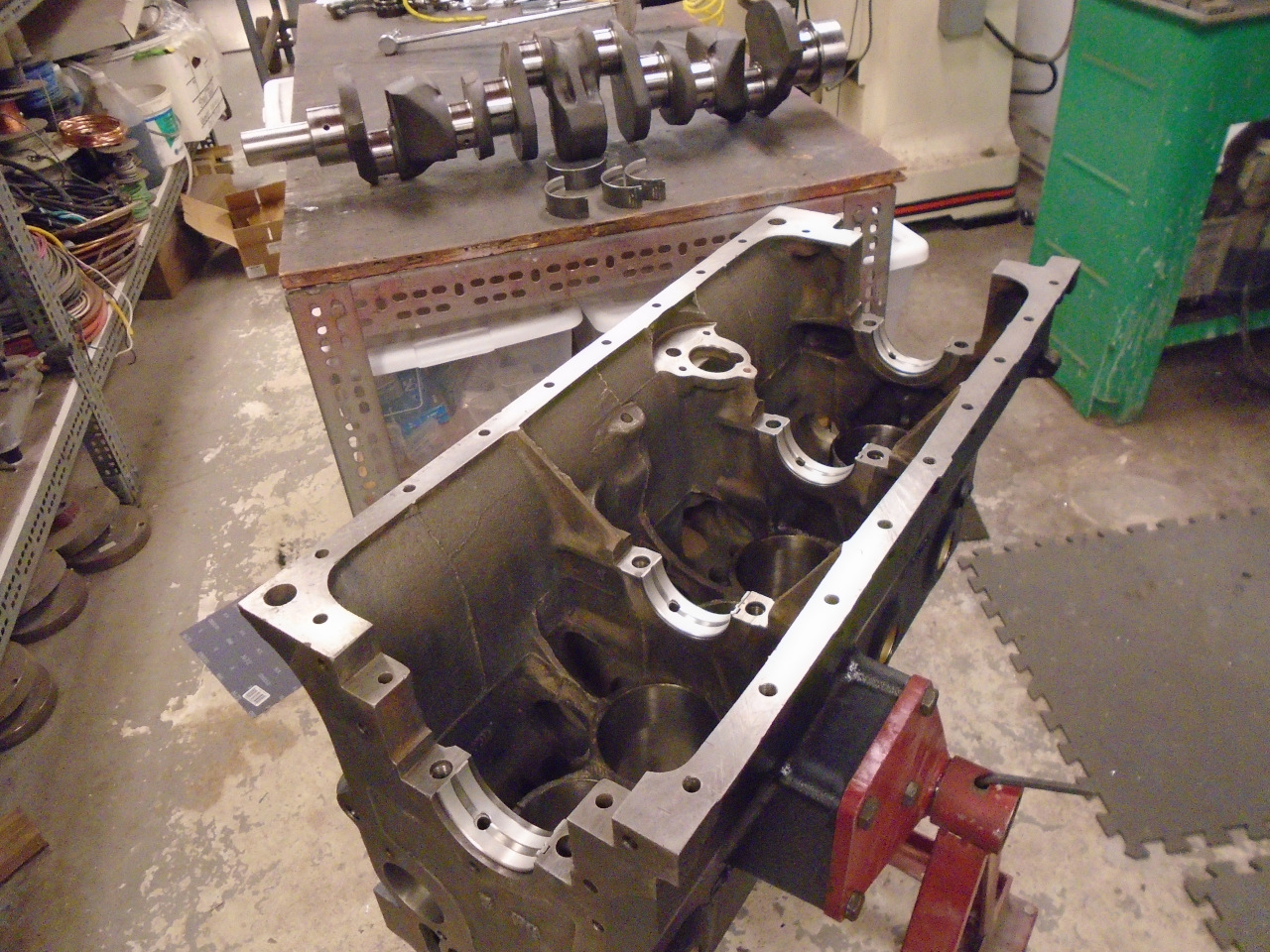

At this point, I realized that I'd forgotten to install the thrust

bearings. These bearings take the end-to-end force of the

crank, and control how much it can move on that direction. I

retrieved the baggie that held the thrust bearings I

removed. In the bag was a pair of standard-thickness

bearings, plus four 0.002" brass shims. I assume it was the

younger me who was responsible for this, and I had a little twinge

of admiration for him because I couldn't really see anything wrong

with the idea.

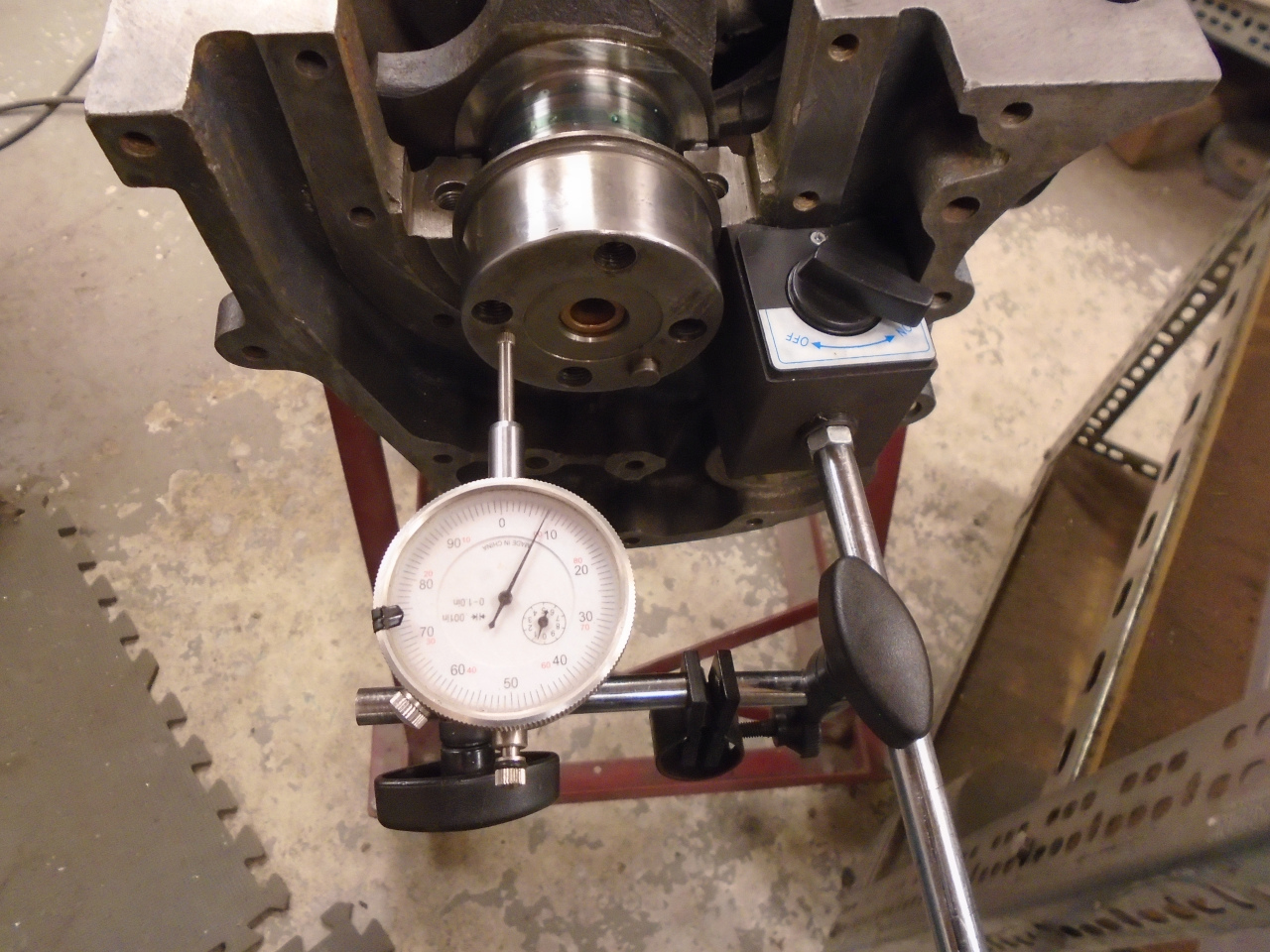

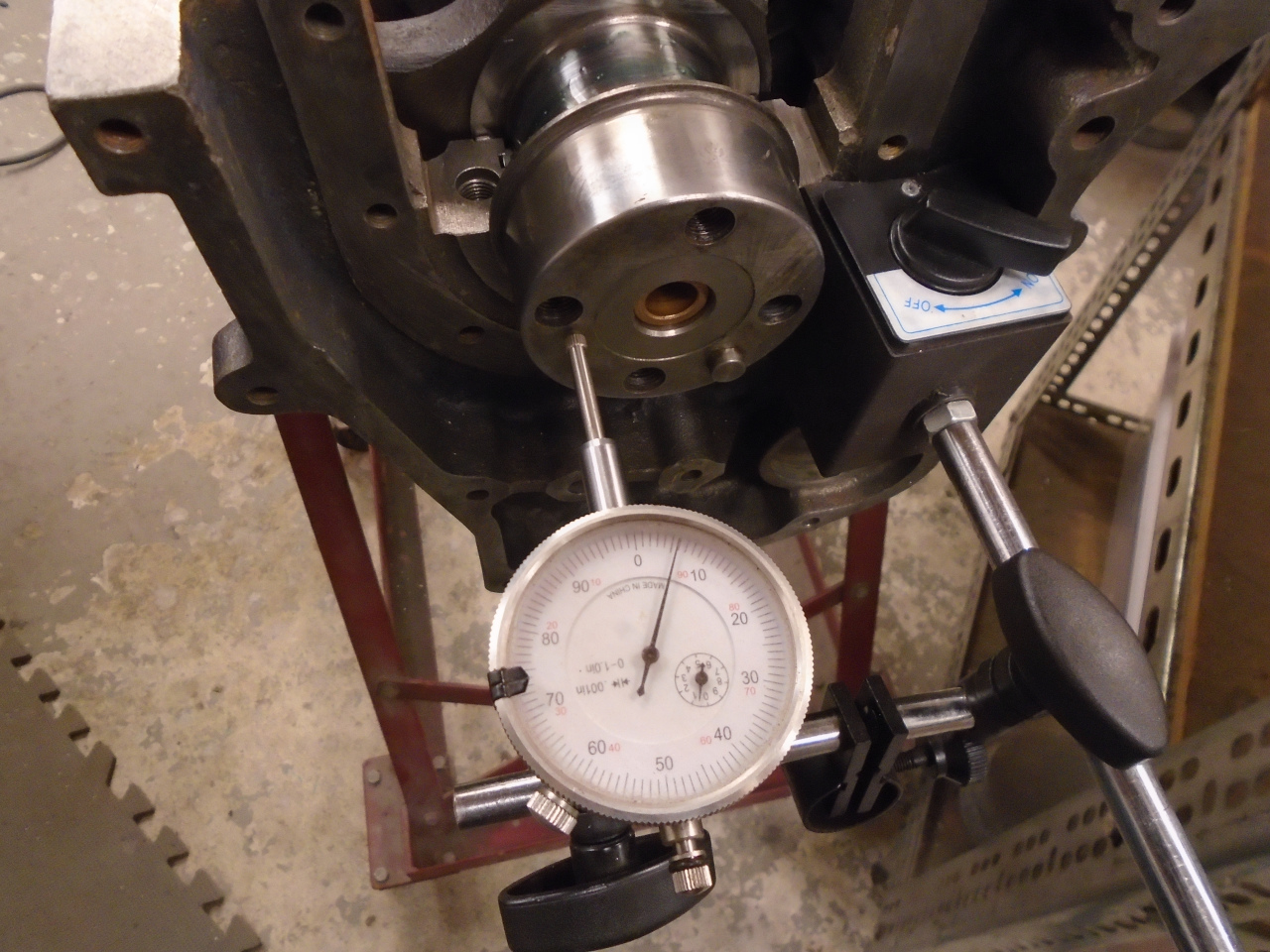

Fortuitously, I had a standard and a +0.005" thrust bearing left

over from my TR6 rebuild, so I installed those and measured the

crank end float, which came out to 0.008". This meets

factory spec, but is the maximum recommended. So, as a

little homage to my 80s self, I popped in one of the brass

shims. This brought the float to 0.006", which made me

happier.

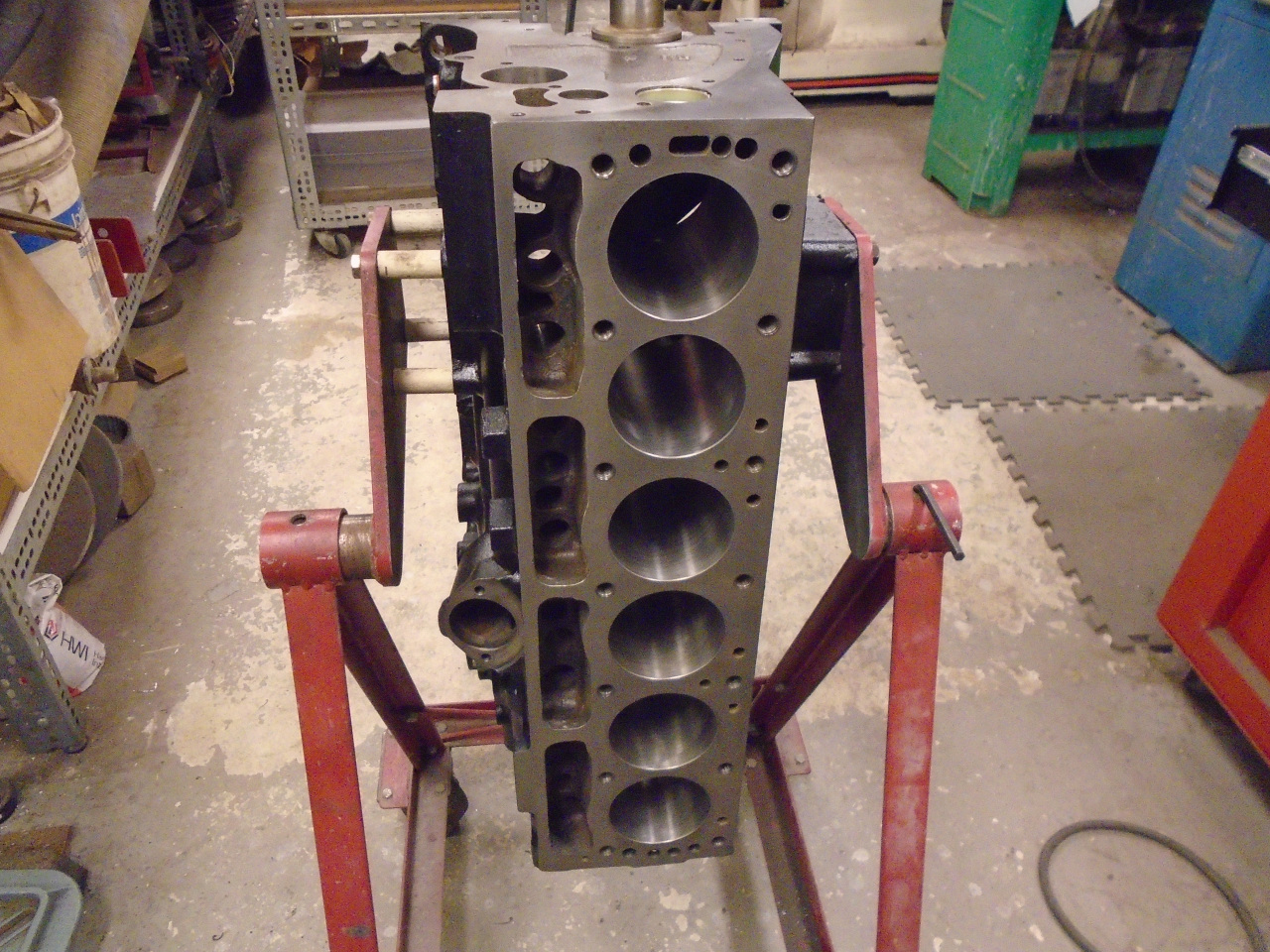

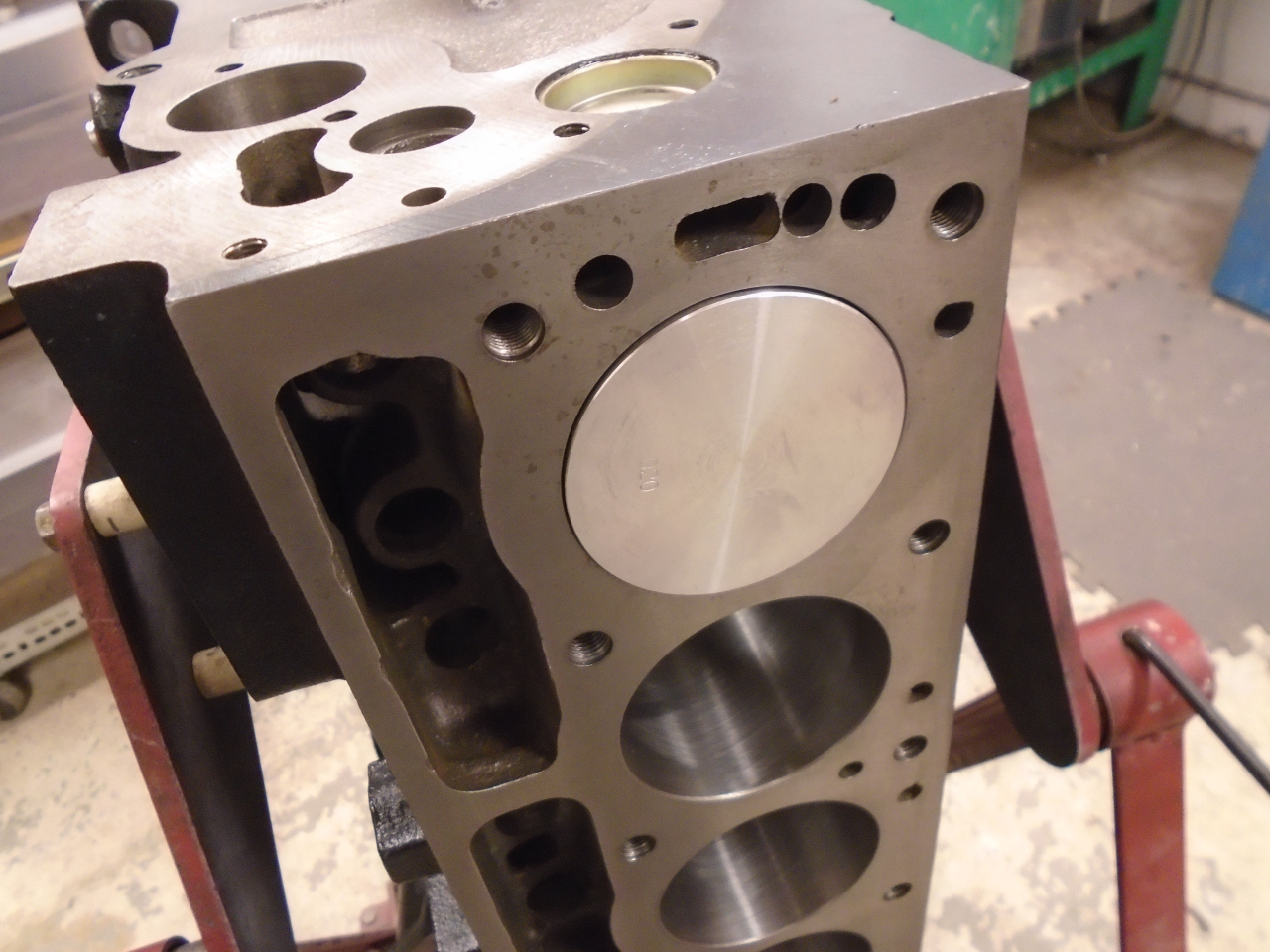

Next up were the pistons and rods. Because of the +0.020"

re-bore, the old pistons would not make the team, but the rods

would, providing there as nothing wrong with them. A quick

check on a flat plate showed that there was no obvious bend or

twist to the rods.

It was at about this time that my Inner Engineer woke up.

"Dude! You need to balance those rods!"

"Really?" I said, rolling my eyes. "This isn't a race car,

you know."

"Doesn't matter, Dude. It's the right thing to do," he said,

jabbing his finger towards me.

"OK, OK. I'll weigh everything. Happy?"

"No! The rods need to be balanced end-for-end."

"What do you mean, end-for-end?"

"Dude! You're losing your skills! The big ends of the

rods rotate with the crank. If they aren't all the same, the

crank balance will be off. You need to make all the big ends

the same weight. The small ends reciprocate with the

pistons. Everything up there in the pistons really should be

the same, too."

"This sounds like a lot of work," I protested, meekly.

"It doesn't have to be. Just use that brain of yours, before

it completely wastes away."

Well, that seemed unnecessarily harsh, but I couldn't deny his

point.

I did a little research on rod balancing. I could buy a

fixture to do it, but they seemed overpriced. There were DIY

versions, but they seemed overly complicated.

What we really need to do is determine the weight of each end of

the rod, but there is a little more to it than just putting the

big end on a scale, then the small end. If the rod is not

level, that is, if the line between big and small end centers is

not horizontal, weight will be shifted to the downhill end.

The commercial and DIY jigs do this leveling with adjustable

hangers or chains.

"But, Dude!" piped up Inner Engineer. "You don't need a universal

rod weighing jig, you just need one for these rods."

"Right!" I replied. " So I just need some sort of fixed bracketry

for these rods. I can measure the rods, do a little

arithmetic, and get the dimensions I need..."

"Now you're firing on all six!"

"...then fab something with aluminum or something."

"Misfire! What about that fancy 3D printer of yours?"

"Of course!" I said. "I'll fire up some CAD."

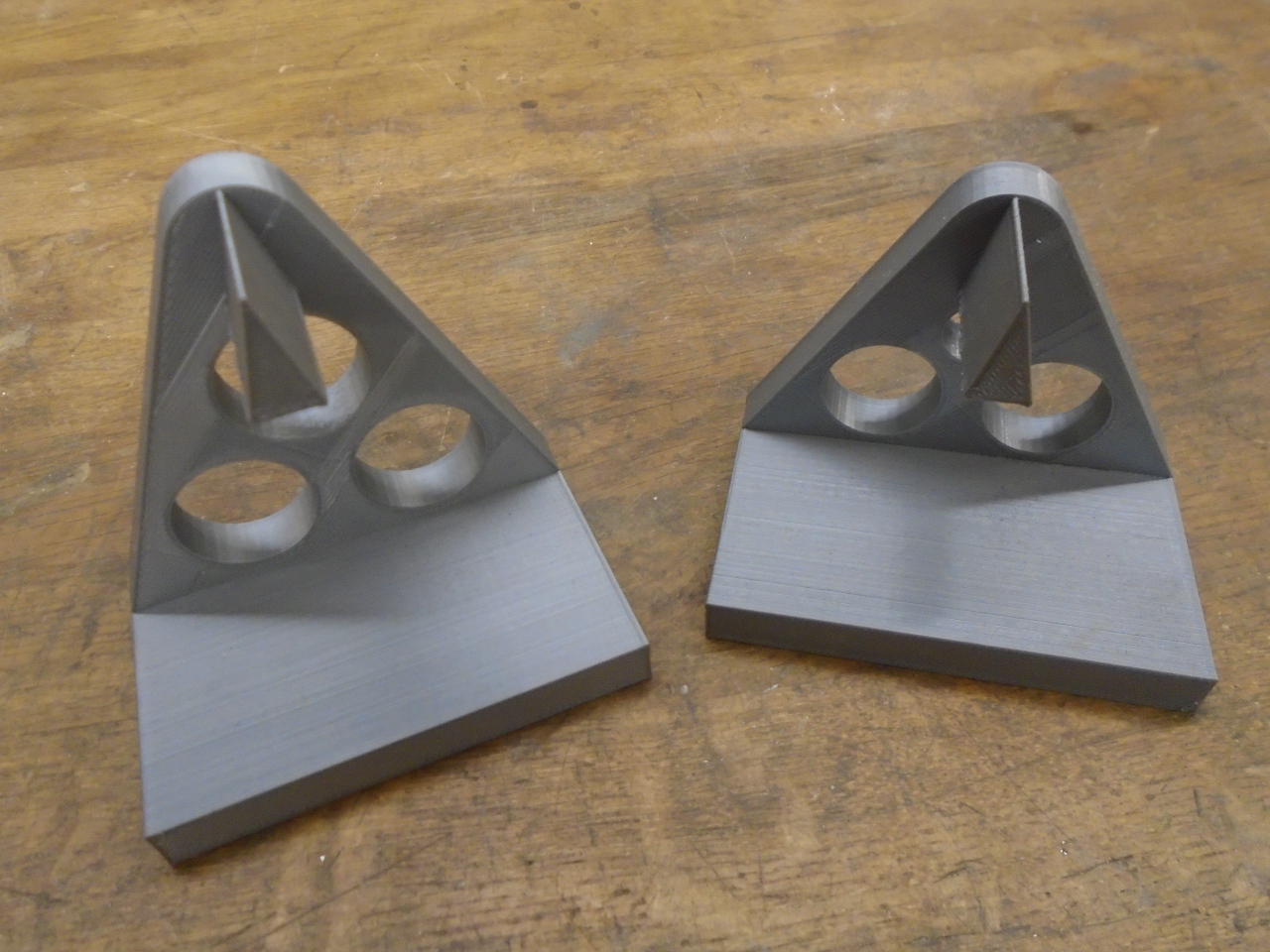

So and hour or so of CAD and five more of printing (when I could

be doing other things), I had these:

The knife edges would hold the rods from the inside of their

bores. The difference in height of the knife edges accounts

for the different bore sizes. Tall bracket for the big end,

short one for the little end, and the rod will be suspended level.

Then, rather than swapping a scale from big to little end, I just

got two of these small scales. They are fairly cheap, have

enough capacity, and are very repeatable in their

measurements. I tacked the brackets to the scale tables with

a little hot glue, and also tacked the scales to a mounting board

such that the distance between the knife edges corresponded to the

distance between the rod bore centers.

After that, it was pretty easy to get weight readings for each

end. I did find that the readings were very sensitive to

slight changes in position of the rod. Very small

displacement left or right would make a difference in the

reading. I addressed this by taking at least ten readings

for each rod, and averaging them.

After determining which rod had the lightest big end, I brought

all of the others down to that weight by grinding in various

places. The range was significant, but not huge. The

big ends ranged from around 506 grams to over 512. I got

them down to within one gram.

As I was pondering doing the same thing to the small ends, it

dawned on me that what really needed to be balanced on the

reciprocating side was the the combination of everything up

there--the rod little end, the wrist pin, the piston, even the

rings. It didn't really make sense to balance all of those

things individually. So I weighed all of those parts.

The pistons varied over about two grams, the pins, a little less

than two. Even the rings varied by nearly half a gram.

Since I also had the overall weight of each rod, and I knew the

big ends were all about the same, the difference was all in the

little ends. So my plan was to match up the lightest rod

with the heaviest of all the other parts, next lightest rod with

the next heaviest of the other parts, et cetera. This would

narrow the spread, and minimize the amount of grinding

necessary. I did all of this on a spreadsheet before I

assembled anything, so I knew how much weight had to be removed

from each rod/piston set. It was only a few grams at

most. I took the weight off of the rod little ends, since

the heavier steel would require less material removal than for the

aluminum pistons.

After all of this, I put together the rod/piston assemblies, and

weighed them. I was overjoyed to find that they were all

within a range of a gram or so.

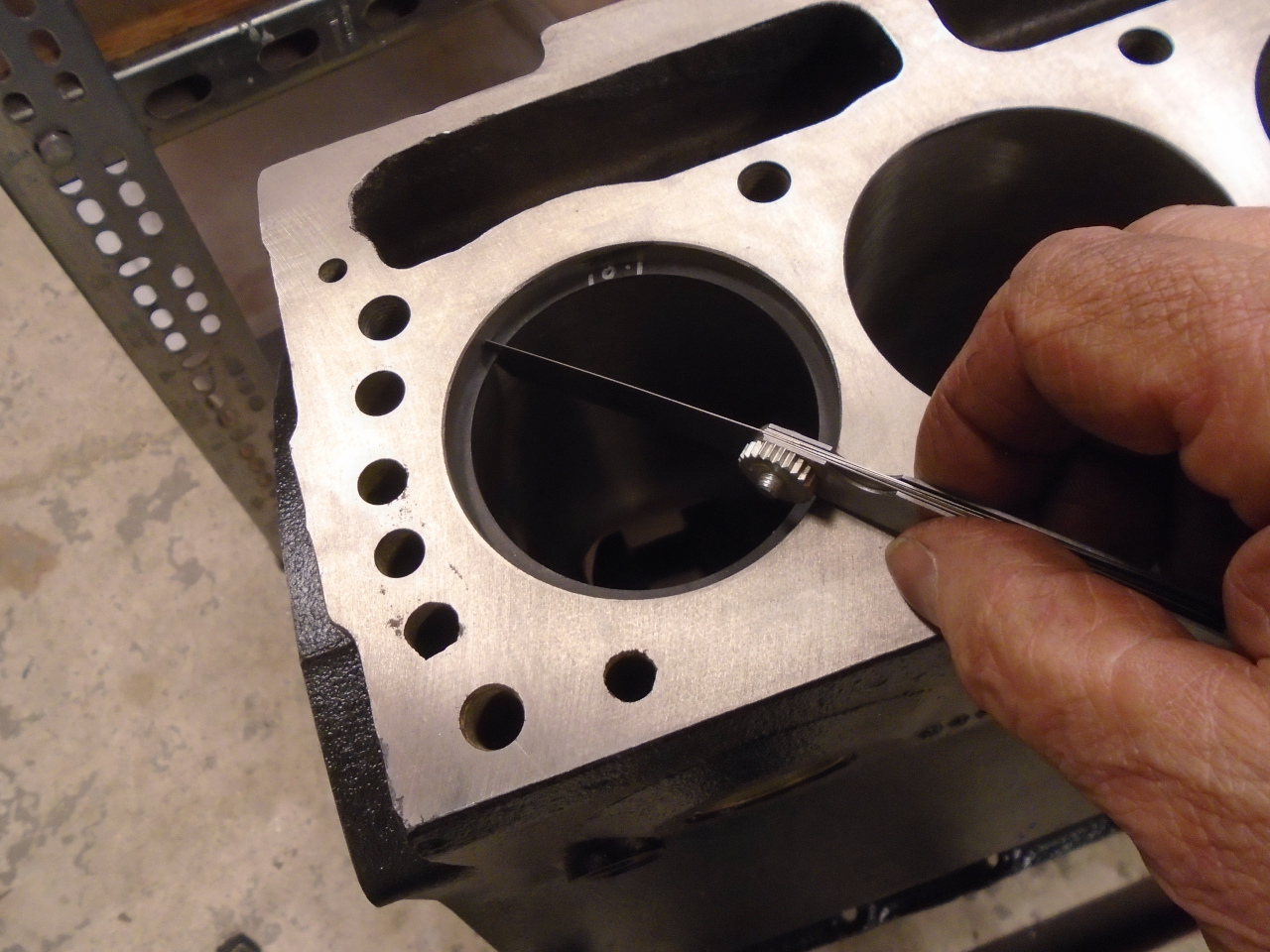

Before installing the rings, I checked the ring gap on a few of

them. They were spot on, so I didn't check the rest.

The assembly process wasn't without a little heartbreak,

though. When installing the rings on the #2 set, I snapped

one of the rings. These are normally only sold in sets, so I

was pretty bummed. I called some vendors. I appealed

to some forums. No one had a single ring to sell me.

Finally, I called Grant Rings, who appears to be the manufacturer

of the rings. As of this writing, I think I have the ring on

the way.

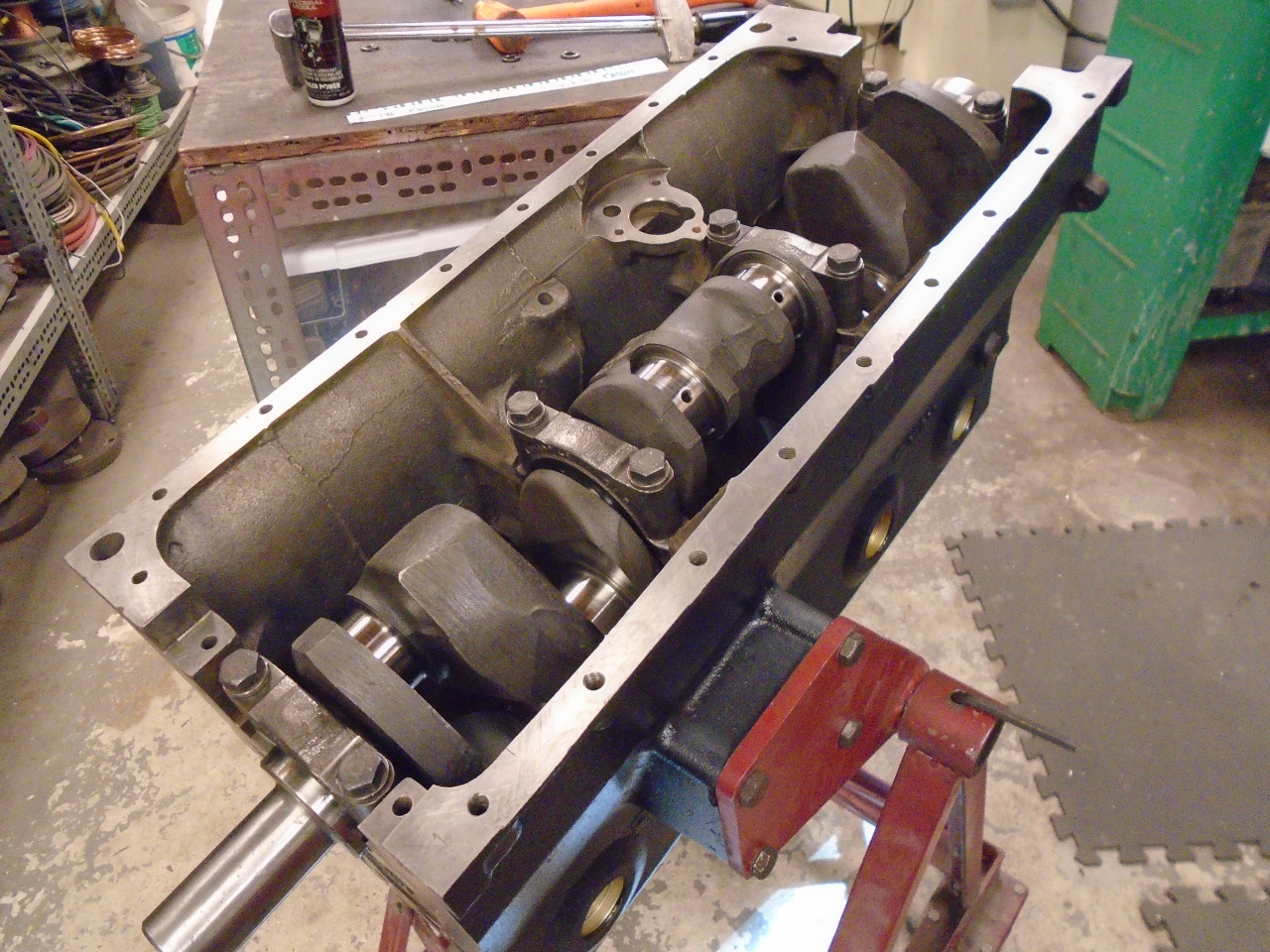

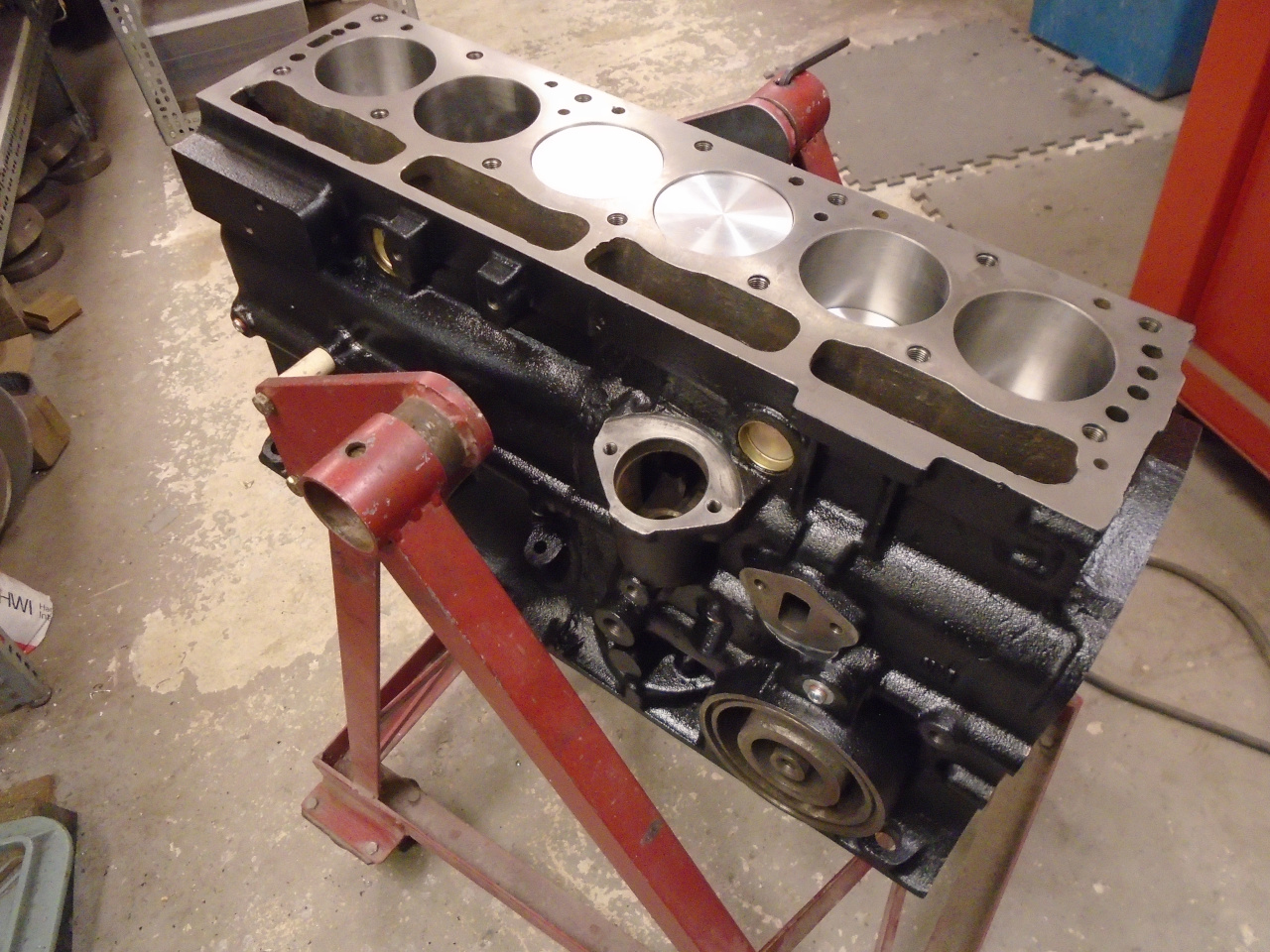

Since I was on a roll, I decided to go ahead and install the five

complete piston sets. I think there are other types, but the

cheap sleeve type ring compressor has always worked well for me.

Before buttoning up the first big end to the crank, I

checked the clearance with Plastigage. Like the mains, it

was a little under 0.002". I'd prefer 0.0015", but I can

live with this.

With each piston, rotating the crank got a little harder.

With five installed, I can barely move it by bare hands twisting

the ends of the crank.

So here we are, tapping our foot, waiting for that last ring.

Jobs like this seem like real progress. It was a fair amount

of work, of course, but only around $300 for the pistons and

rings.

Comments to Ed at elhollin1@yahoo.com

To my other GT6

pages.