To my other GT6

pages

July 9, 2020

Rear Wheel Wells

For the 1969 model year, Triumph re-engineered the

GT6 rear suspension from the previous swing axle arrangement to

an improved design using a rubber "Rotoflex" coupling at the

outer ends of the axles. The largish coupling also

required moving the tubular dampers outward for clearance.

Instead of mounting the tops of the dampers on a frame bracket

as in previous models, they were attached to brackets mounted on

the wheel well sheet metal.

Even at the time, this was surely considered a bad idea by many,

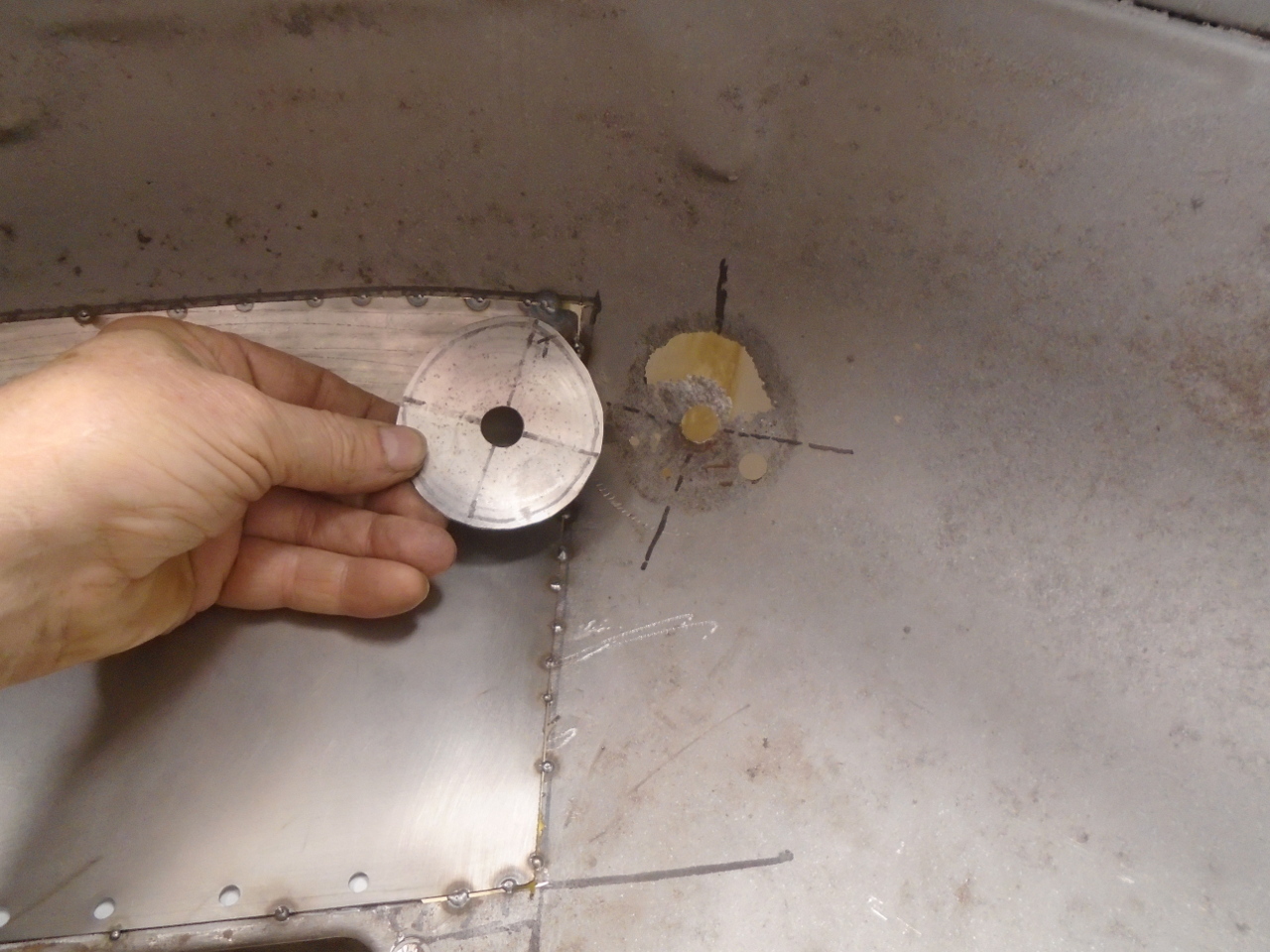

but the actual execution made it worse. The wheel wells

were strengthened by formed doubler plates spot welded to them,

and the shock mount brackets were welded to the doubler.

The brackets also included a bump stop (missing in the picture),

which didn't help any.

The main problem here, at least on my car, was that water got

between the wheel well and the doubler, and went to work.

The result was a total rust through along the top of the

doubler, and at the bottom.

To get at all the rust, I had to remove this cross piece.

On some GT6s, this piece is bolted to brackets on each side, but

on my car, it was welded in.

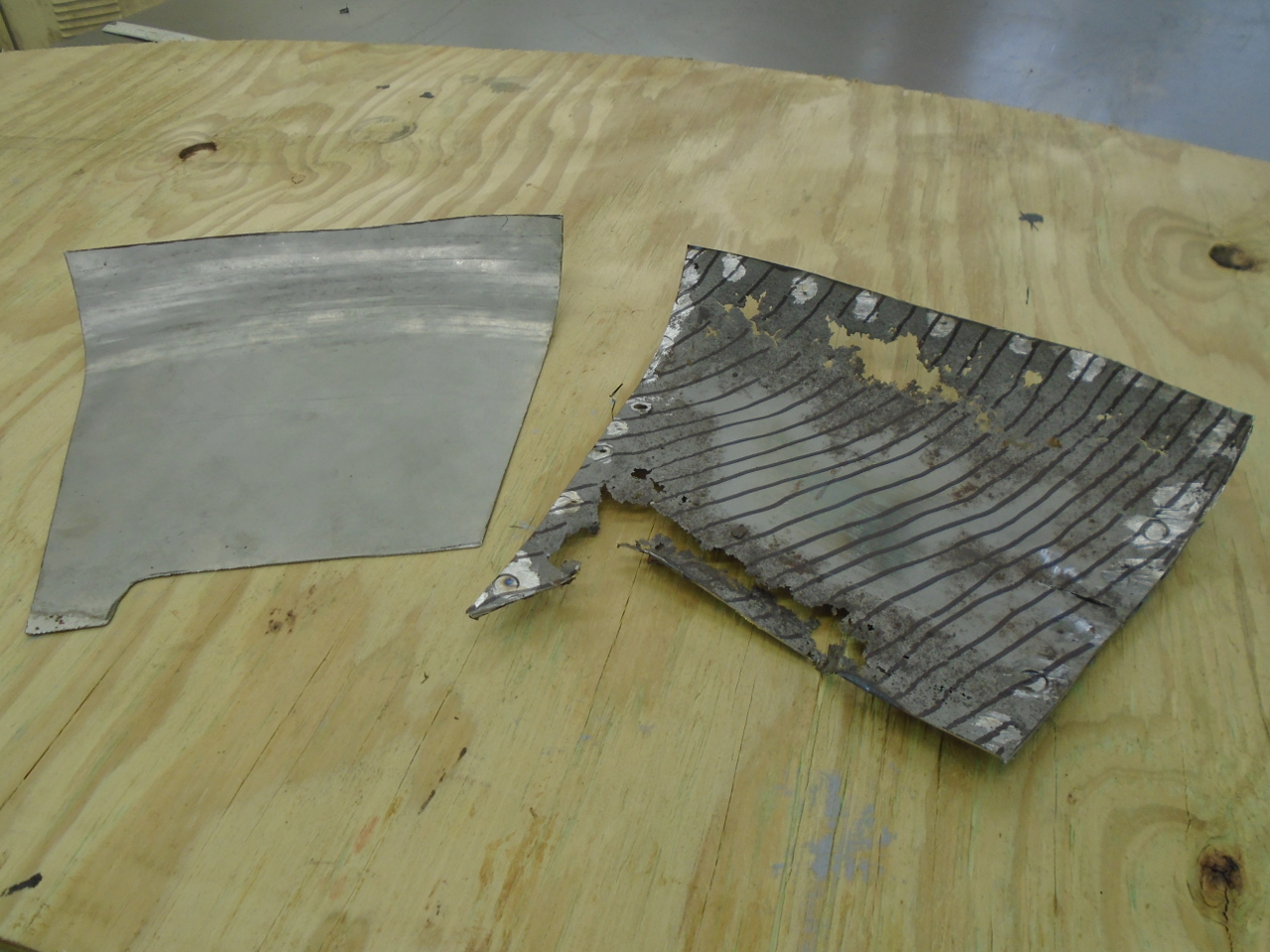

The doubler plate is held by a few dozen spot welds. I

intend to make other arrangements for mounting the dampers, so I

won't be replacing these.

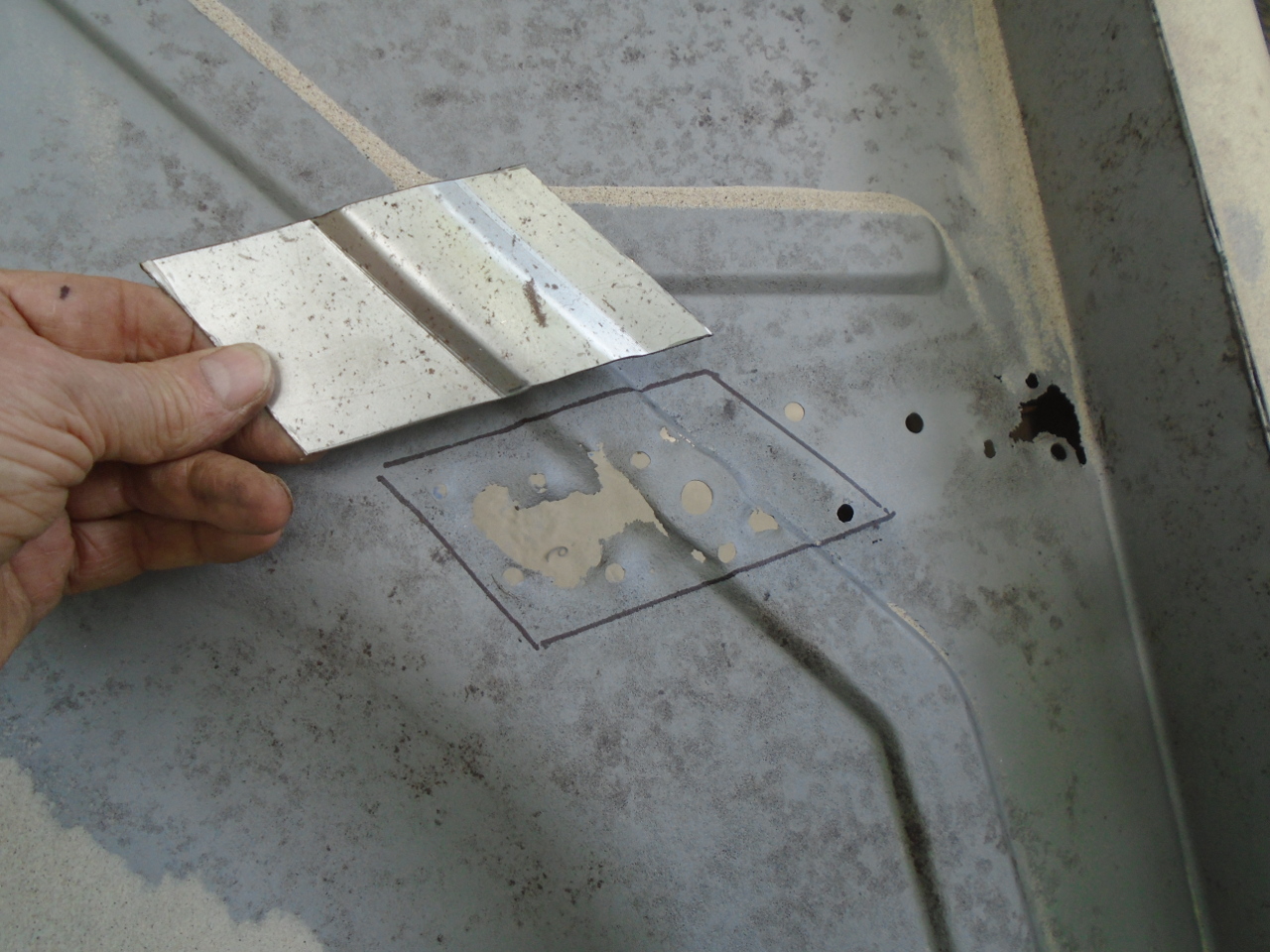

A lot of rust underneath. Sandblasting it away helps to

see the real damage.

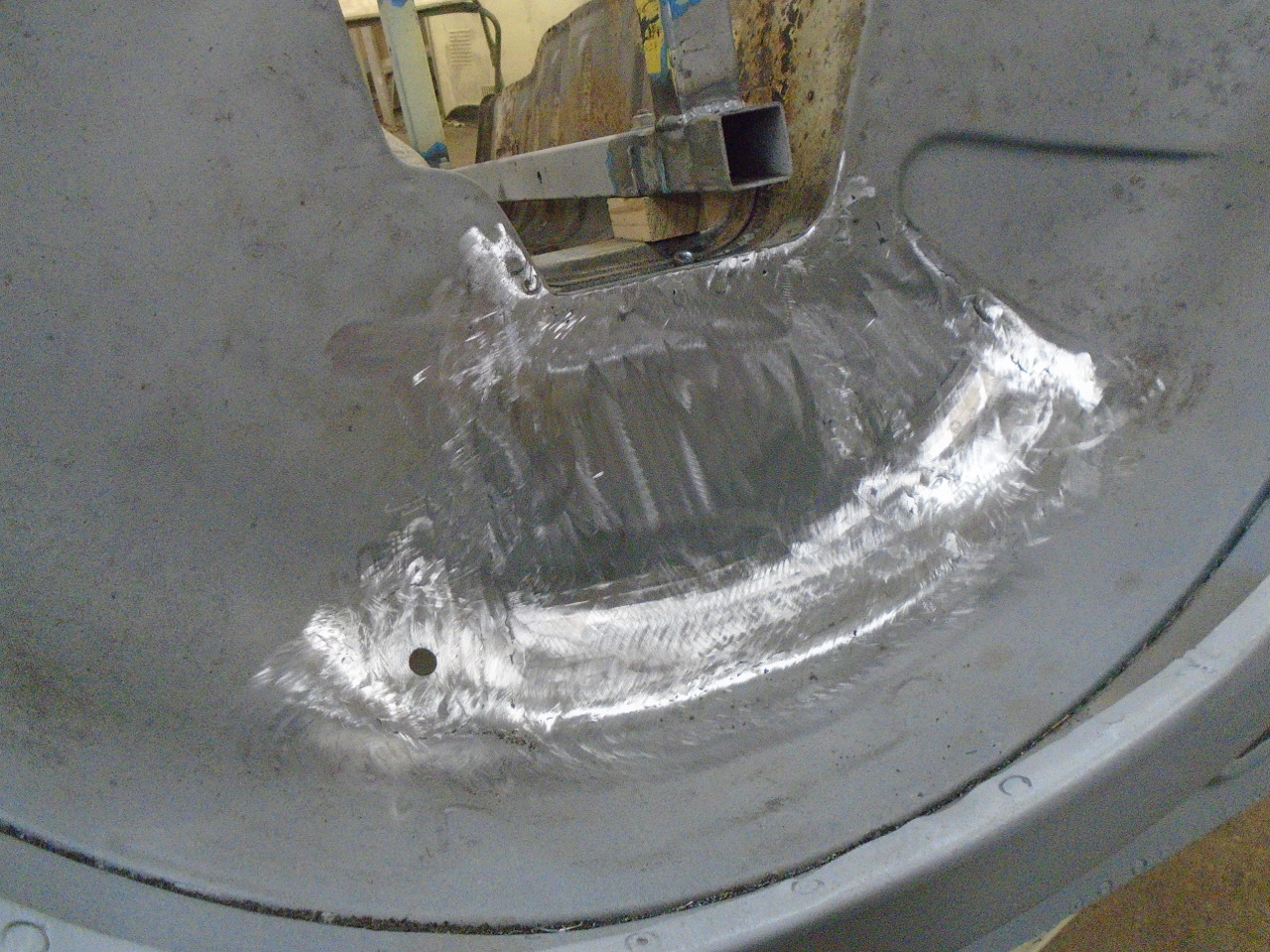

I decided to fix the bad area with two patches. I was

pretty freaked about the compound curves, and didn't think I had

the skills to do it all in one go. There seemed to be a

subtle curve change near the middle line of spot welds, so that

is where I joined the two patches.

This is the large patch. The compound curve at the top was

roughed out with multiple passes through my bead roller with a

soft bottom roller. It took a lot of hand tweaking after

that.

Cut out the bad area...

...and tack in the new piece.

The smaller patch was similar.

The other side was almost identical.

One side also had a lot of rust behind a welded nut. I

think it's for a seat belt anchor.

Finished the welding. I did it from the outside because it

took less contortion.

Then cleaned up the welds.

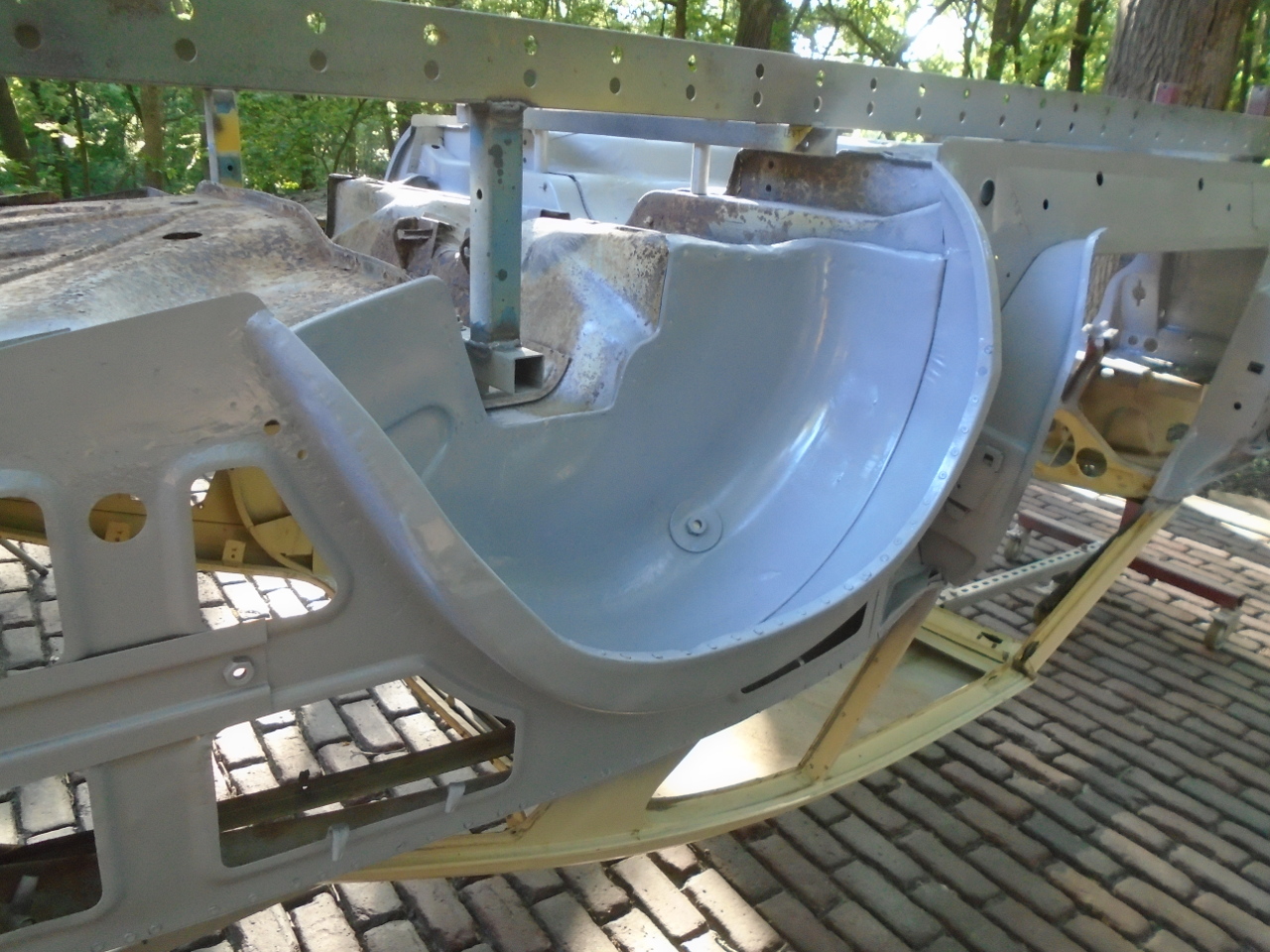

Blasted everything for a nice tooth...

...And sprayed on a nice epoxy primer to lock it in against our

wonderful Midwest humidity.

This is the end of all the rust repair on the car that I know

about. I know that when I go poking around, I'll probably

find more.

UPDATE--July 15, 2020

I blasted and primed the floor between the wheel wells.

This went fine, without any heartache.

Then turned to the crosspiece that supports the finish floor

panels at the rear. I had blasted and primed it previously

since it would be hard to get the bottom side with it

installed. Re-installing the crosspiece should have been a

simple job, but sadly, I found that in the week or so since I

removed it, the piece had shrunk by about three-quarters of an

inch. The gap was about the same on both sides.

I suppose this was just because the shape of the new wheel wells

is a little different than original. To fix it, I just

flattened the wider side tab on each end, and re-bent it further

out. For the narrow tab on the top, I cut it off and

welded in a new piece that extended further.

That made it fit pretty OK.

So I welded 'er in.

This of course messed up the primer on the inside of the well,

so I took the opportunity to weld in the original seat belt

anchor nut on top of the patched area.

At this point, the only area of floor left to do was the

boot. When I blasted the rust and paint off, it uncovered

a couple of rust-through areas right on top of a bottom-side

stiffener for the spare tire hold down.

Removing the stiffener revealed that it needed to be patched.

Then the floor itself. Unfortunately, the damage included

one of these strengthening ribs, but on hte other hand, the rib

is the same size as the ones on the forward floors, so I could

use the same tooling to make the patch.

Patches welded in, and the stiffener replaced.

Then primed the floor.

I feel like I've gotten somewhere now.

This seems like a small milestone, and I hope the worst of the

rust damage is now behind me.

Comments to Ed at elhollin1@yahoo.com

To my other GT6

pages