To my other GT6

pages

March 21, 2020

Cylinder Head

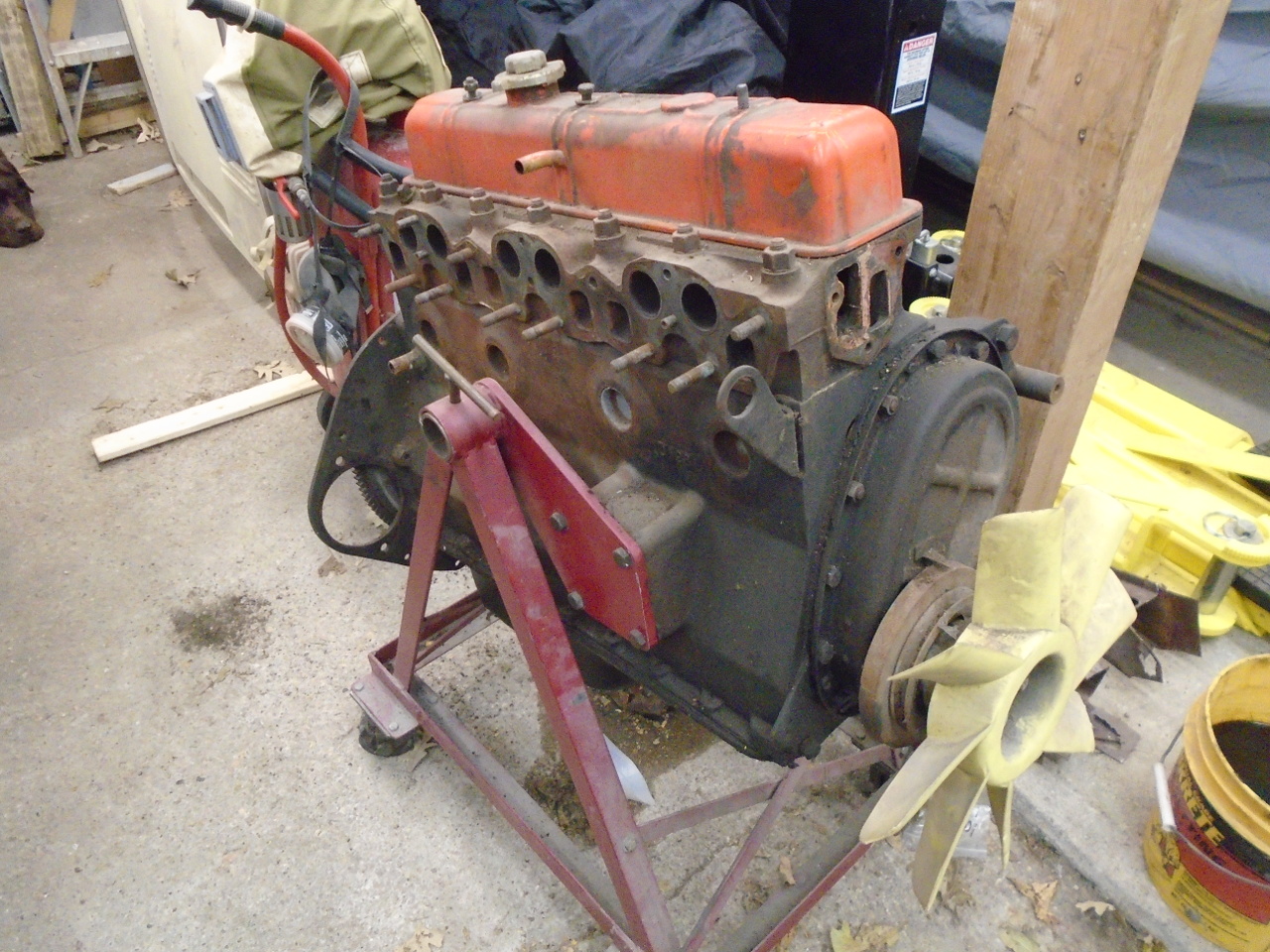

The straight six engine in the GT6 is certainly

outdated by modern standards, and was a pretty mature design

even in its own day. It's a very conventional overhead

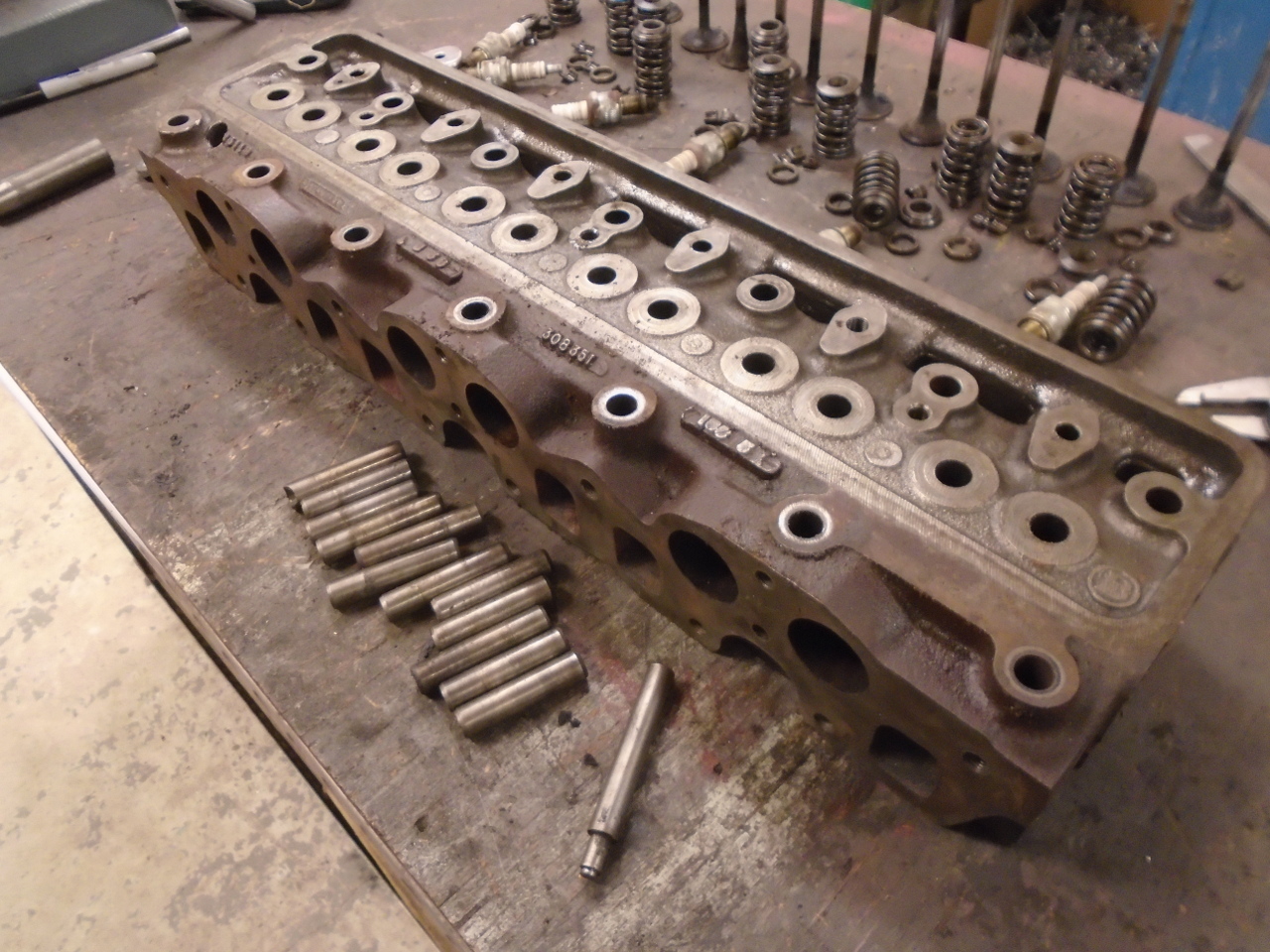

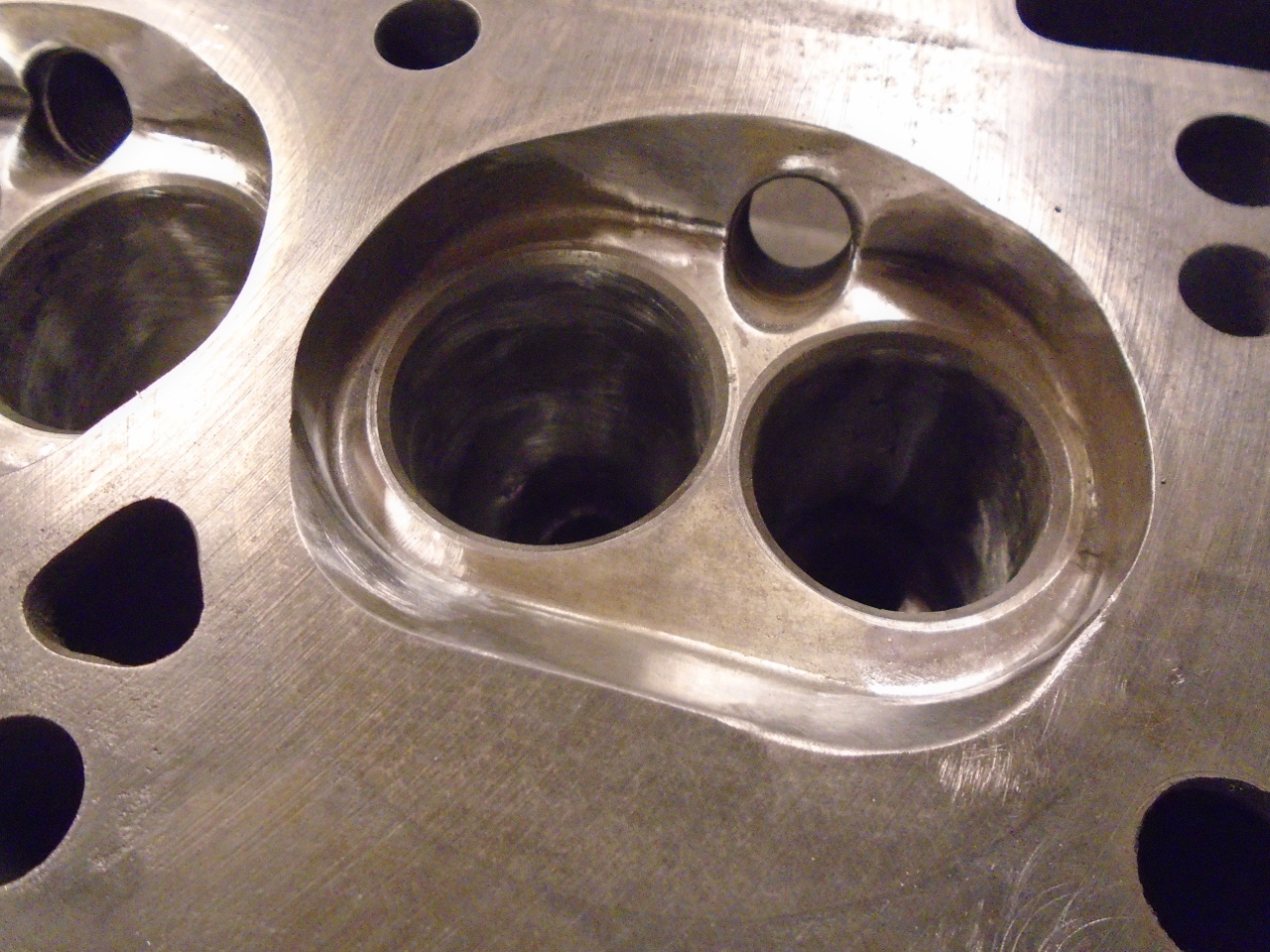

valve pushrod engine. The cylinder head is a beefy

60-pound lump of cast iron that holds the combustion chambers

and their two vertical valves each.

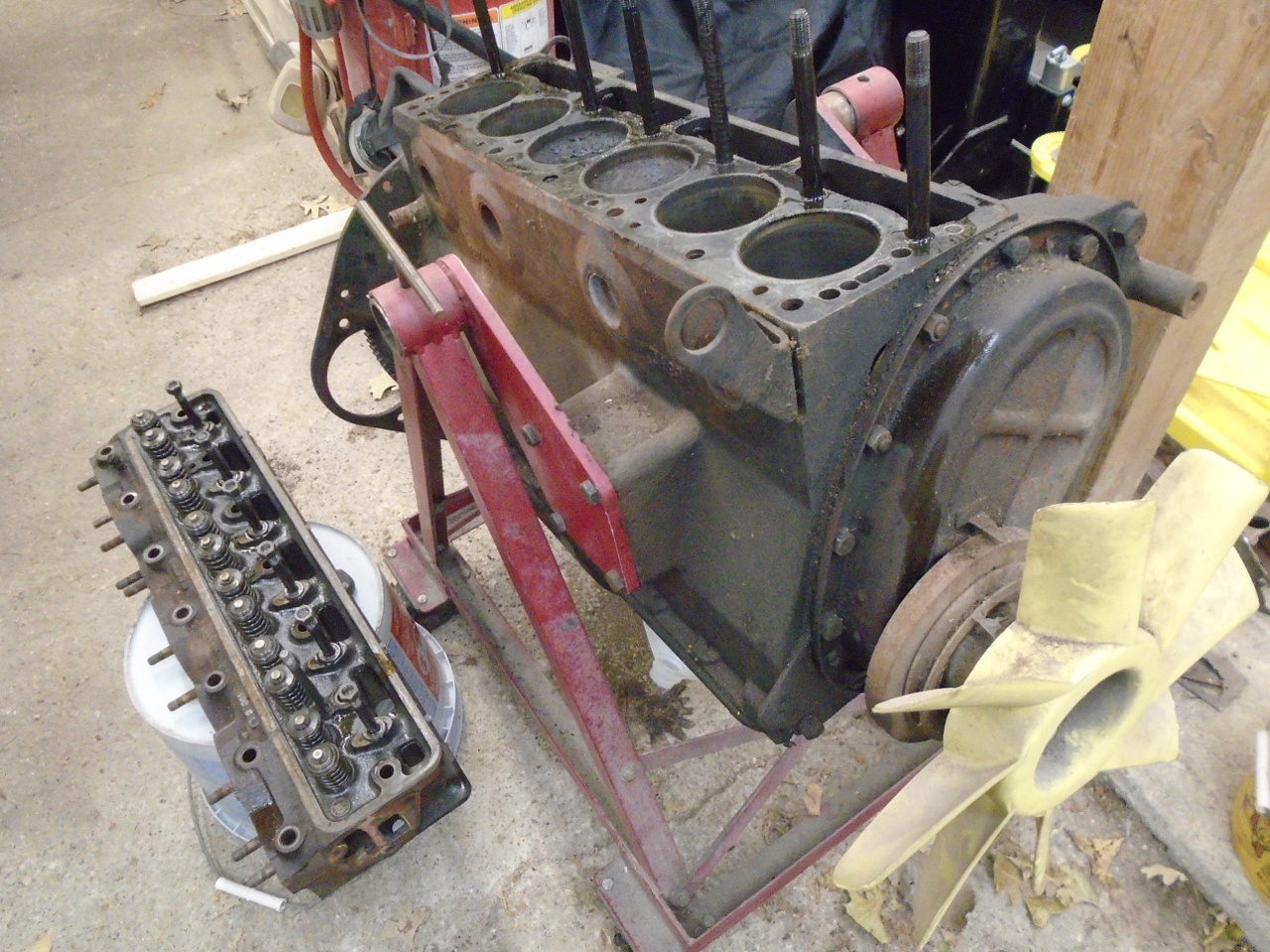

The first task on the cylinder head was to detach it from the

engine. I understand that this can sometimes be difficult,

but in this case, the head came along peacefully.

I cleaned off a bench for disassembly and inspection.

There weren't any big surprises.

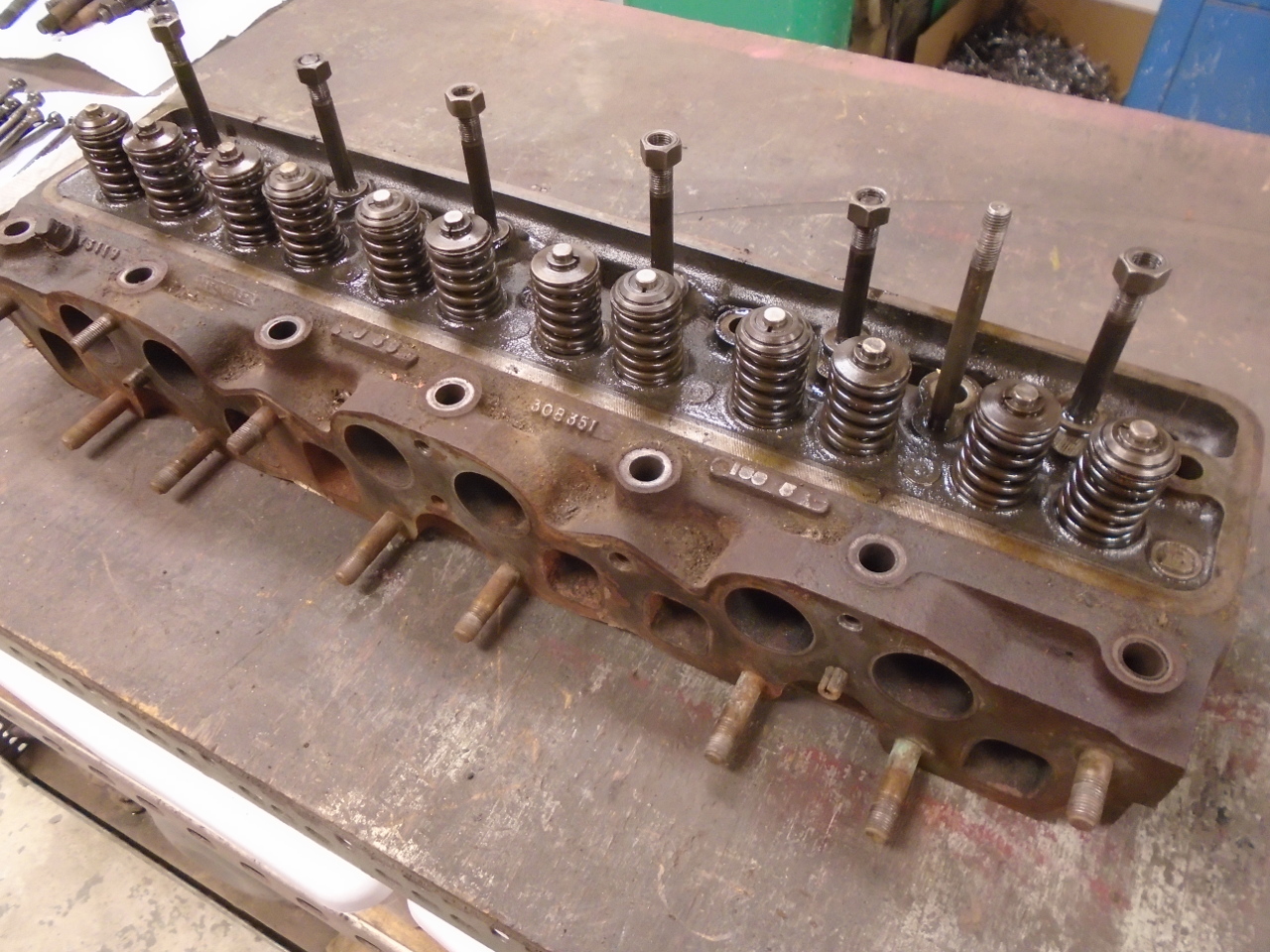

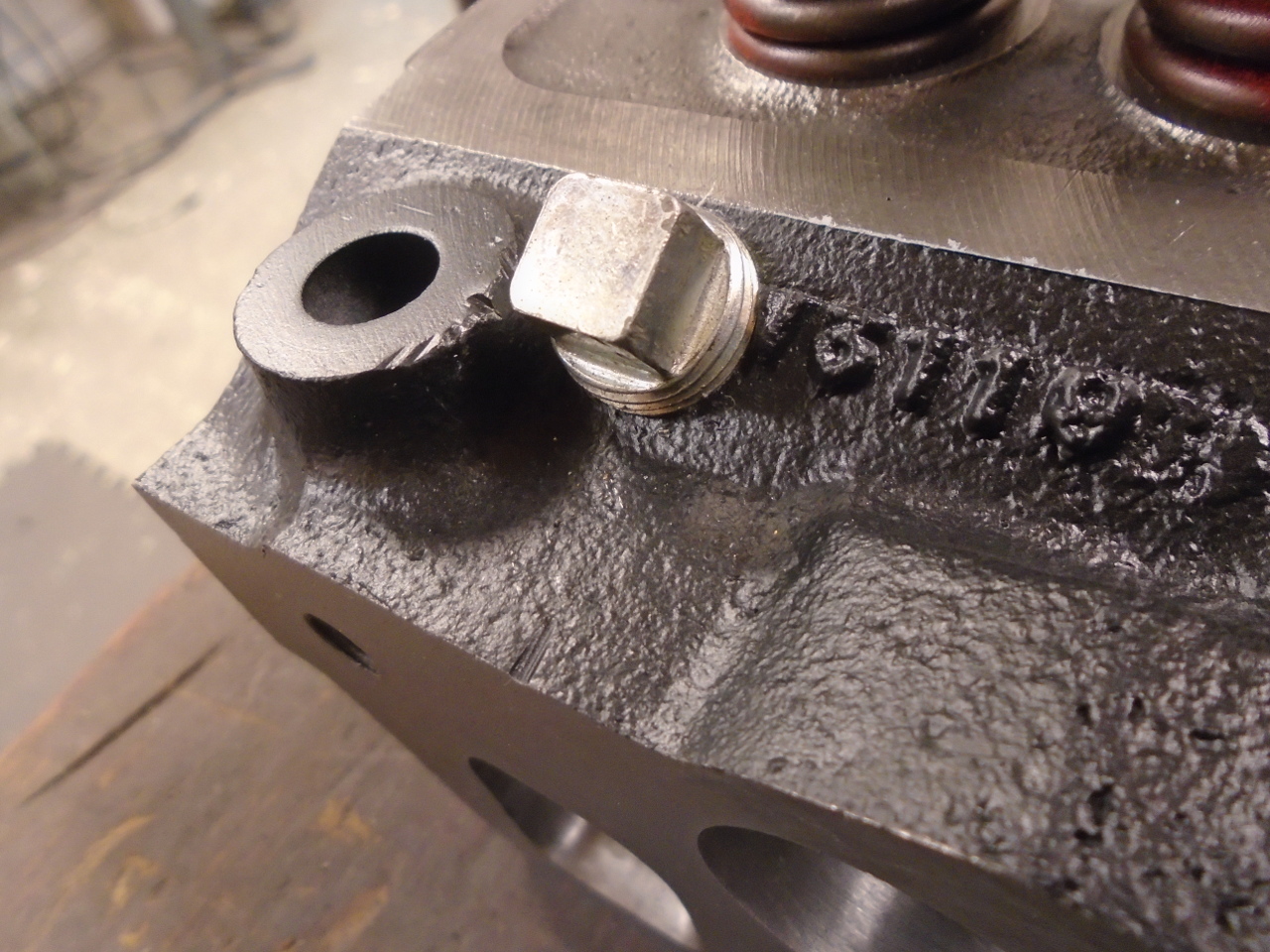

Disassembly was fairly routine. The water jacket plug at

the rear showed a little defiance. I had to drill it out.

Also, the core plugs didn't respond to polite requests.

The remaining studs and valve gear came away without too much

undue violence.

The only remaining removable items on the head were the valve

guides. The valve stems didn't feel too bad in the

guides. The valve stems did measure slightly out of spec

on the small side, but this was compensated for by a "knurl" on

the inside of the guides. According to some notes I found

in my Haynes manual, this is something I had done in the early

80s to address the stem wear. Also, a couple of the guides

were chipped on top.

All of this was enough for me to decide to replace the guides,

so out they came. The piece to the right of the guides is

the drift I used to push them out.

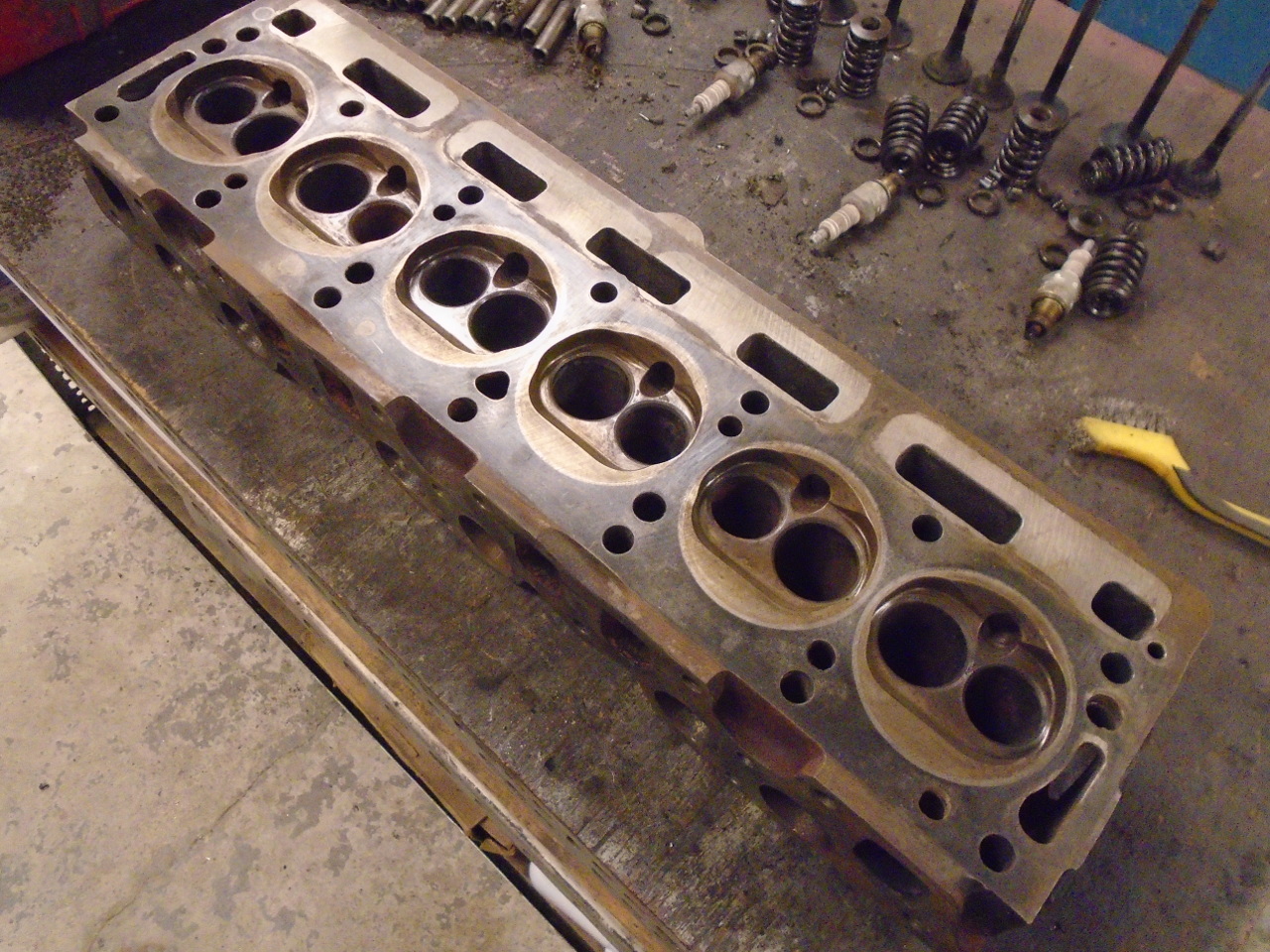

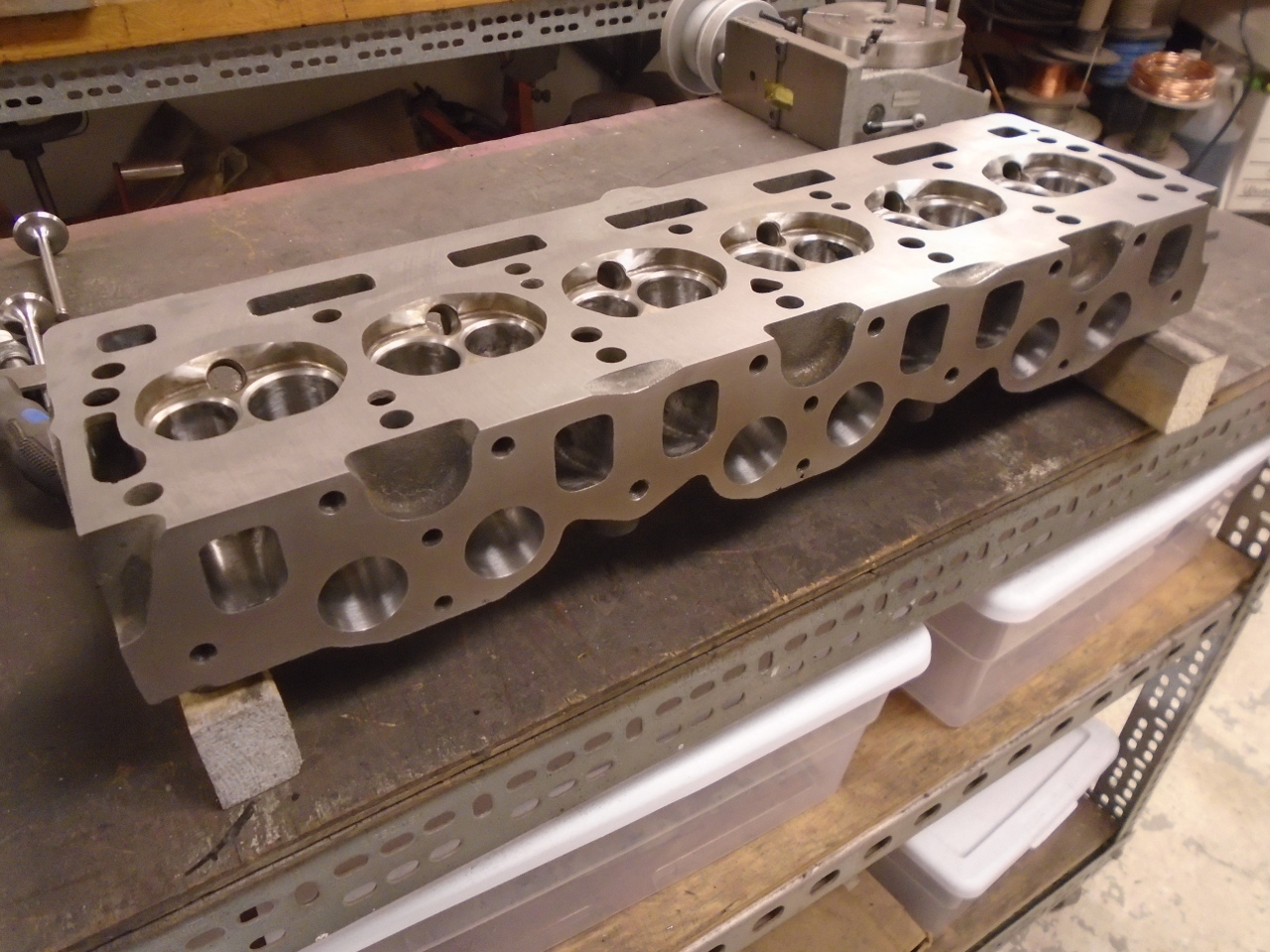

So at this point, I had a bare head, and the usual thing would

be to clean it up. It is common to have the things like

this "tanked", or "hot dipped". These processes are

usually a hot caustic solution that dissolves away the burnt,

caked oil, grease and carbon. I've had it done before, and

was often disappointed. It didn't seem to do much for the

rust, or for the internal scale in the coolant jacket.

With judicious choice of chemicals, I thought I might be able to

do as well or better at home.

I took the head to one of those DIY car washes with the high

pressure hot soapy water to clean off what it could--mostly the

oil and some of the carbon. The rest of the carbon and the

combustion chamber deposits came off pretty easily manually.

What then remained was rust and scale, and these things are

better addressed with acids. I made a box, lined it with

plastic, and put the head in it.

Then added enough phosphoric acid to fill and cover the

head. Though there are stronger, quicker acids, phosphoric

has the advantage of being a little safer to use, and it doesn't

stink.

An hour later, the foaming suggested that the acid was doing

something. Phosphoric acid at this concentration has very

little effect on metallic iron, but does attack other

substances. I left the head in the bath over night.

After a rinse and compressed air dry the next day, the head

looked quite a bit cleaner, especially inside.

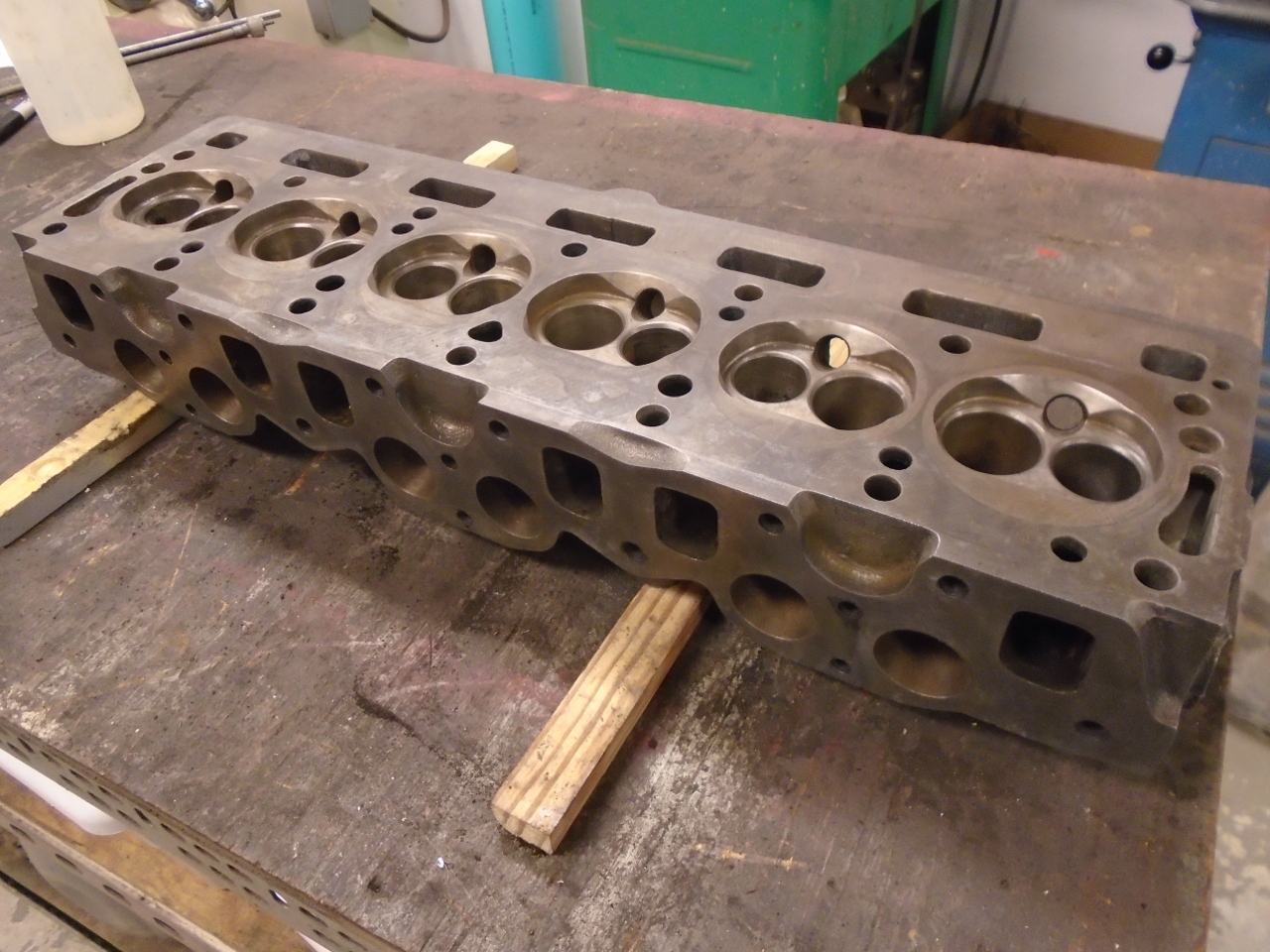

I had been thinking all through this process about possibly

bumping up the compression ratio a little bit on this car.

I did some research to try to find out what the stock CR was,

and was met with confusion. The ratio varied not only by

model and year, but also my market. I read figures between

7.5 and 9.5. The only way I saw to be sure was to

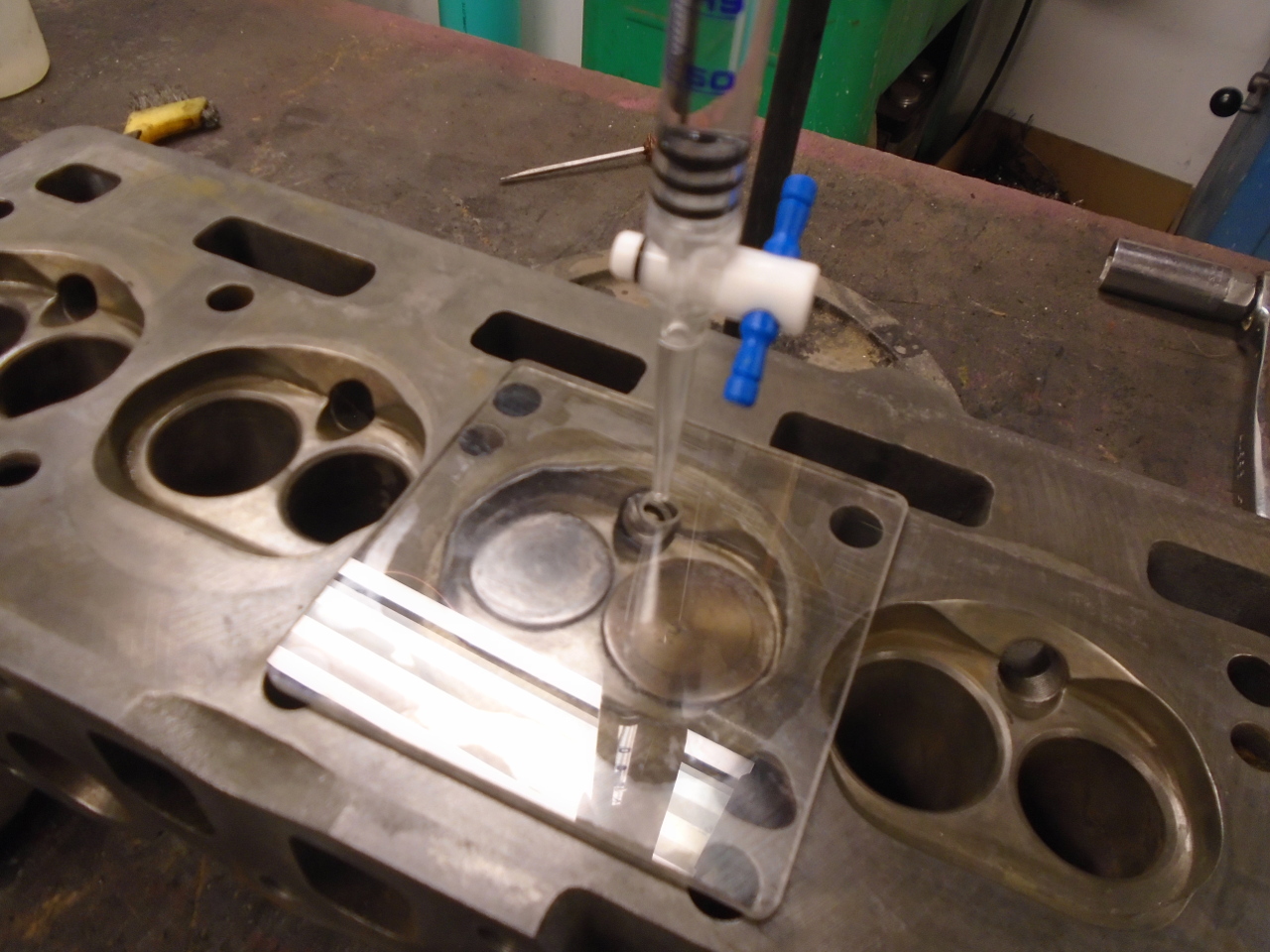

calculate it myself. One of the most important inputs for

this calculation is the combustion chamber volume, and I'd have

to measure it.

This is not frontier science. People have been doing it

for many decades. It just involves measuring how much

liquid it takes to fill the chamber. Typically, the

chamber is covered with a clear panel and the liquid is added

through a small hole until there is no more air in the chamber.

I assembled the needed equipment and checked a couple of the

chambers. The valves and top cover are sealed with

Vaseline.

The subsequent calculation yielded a compression ratio of a

little under 9:1. However, I had some recollection of

having had the head shaved back in the 80s. Some more

research revealed that the stock head for this car should have

had an overall thickness of 3.300 inches. Mine measured

about 3.290", so it appeared that I'd had about 0.010" taken

off. Working backwards, this implies that the stock car

must have had a CR near 8.75:1.

I decided I'd like a CR of around 9.5:1, and calculated that an

additional 0.030" removed from the head should deliver something

close to that. I briefly mulled doing the shaving myself,

but it's a little big for the tooling I have, so I resolved to

send it out. Besides, I certainly didn't have the

equipment to do a three angle valve seat grind, so the head was

going to have to go to the shop anyway.

Before hauling the head to the shop, I took a little time to

address a few small mods to the ports and the combustion

chambers.

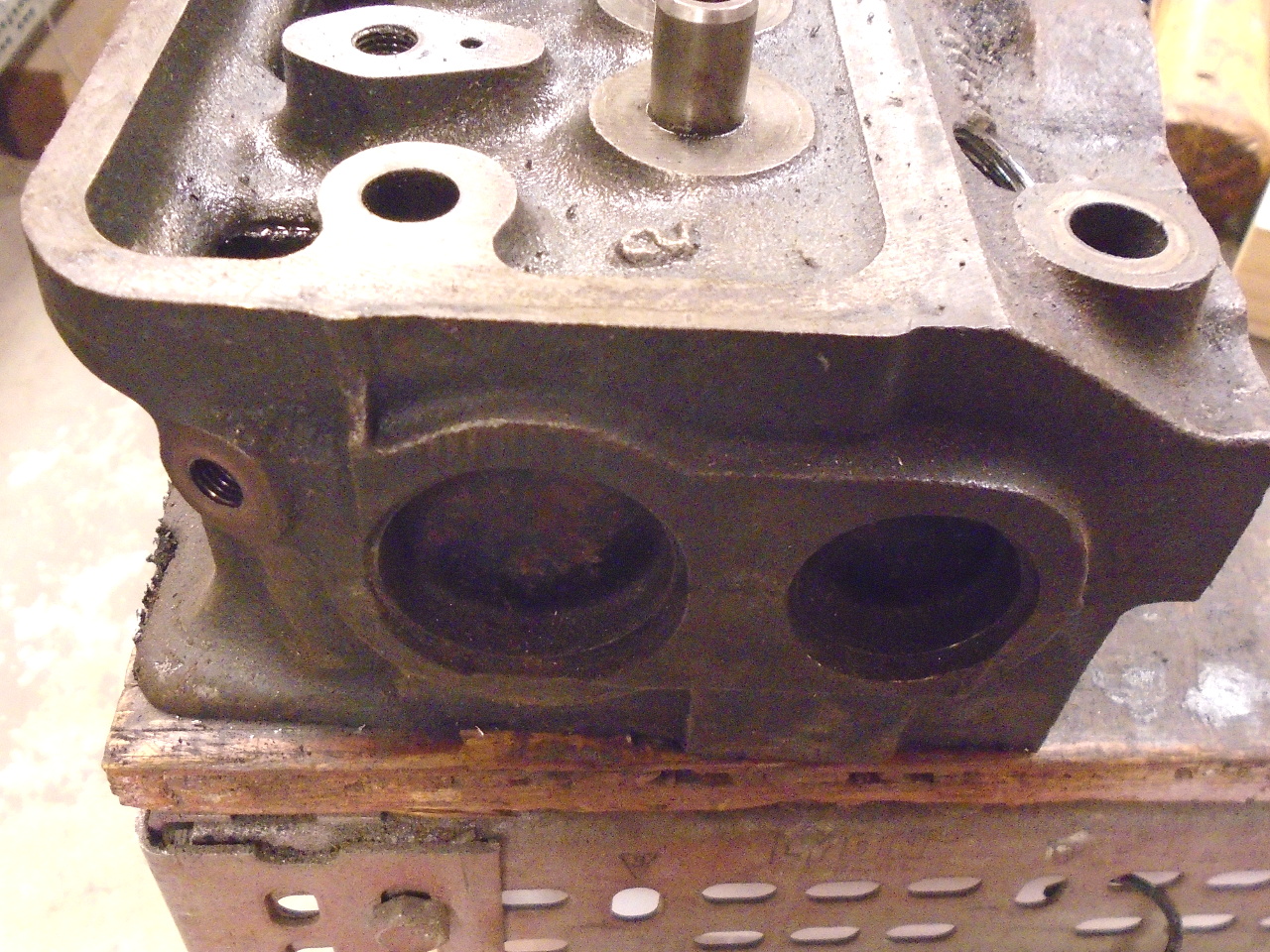

The exhaust ports on this head have a sizeable boss in the roof

of the pocket above the valve. The boss is to support the

lower end of the valve guide. That feature offers some

restriction in flow, and since it is larger than it needs to be,

it's a common mod to reshape it to reduce the restriction.

The exhaust ports also got some minor reshaping to maintain a

relatively constant cross section through most of their

length. This little template, which fits the port opening,

was used to determine where to grind. The idea is that the

template should be able to pass through the length of the

port. Something similar was done for the intake

ports. The amount of material removed was pretty minimal.

The only other grinding mod to the head was to blunt the

"eyebrows" in the combustion chambers. These are sharpish

"creases" on either side of the spark plug opening, and also on

the opposite side of the chamber. These can reportedly be

hotspots in the chamber and lead to premature preignition.

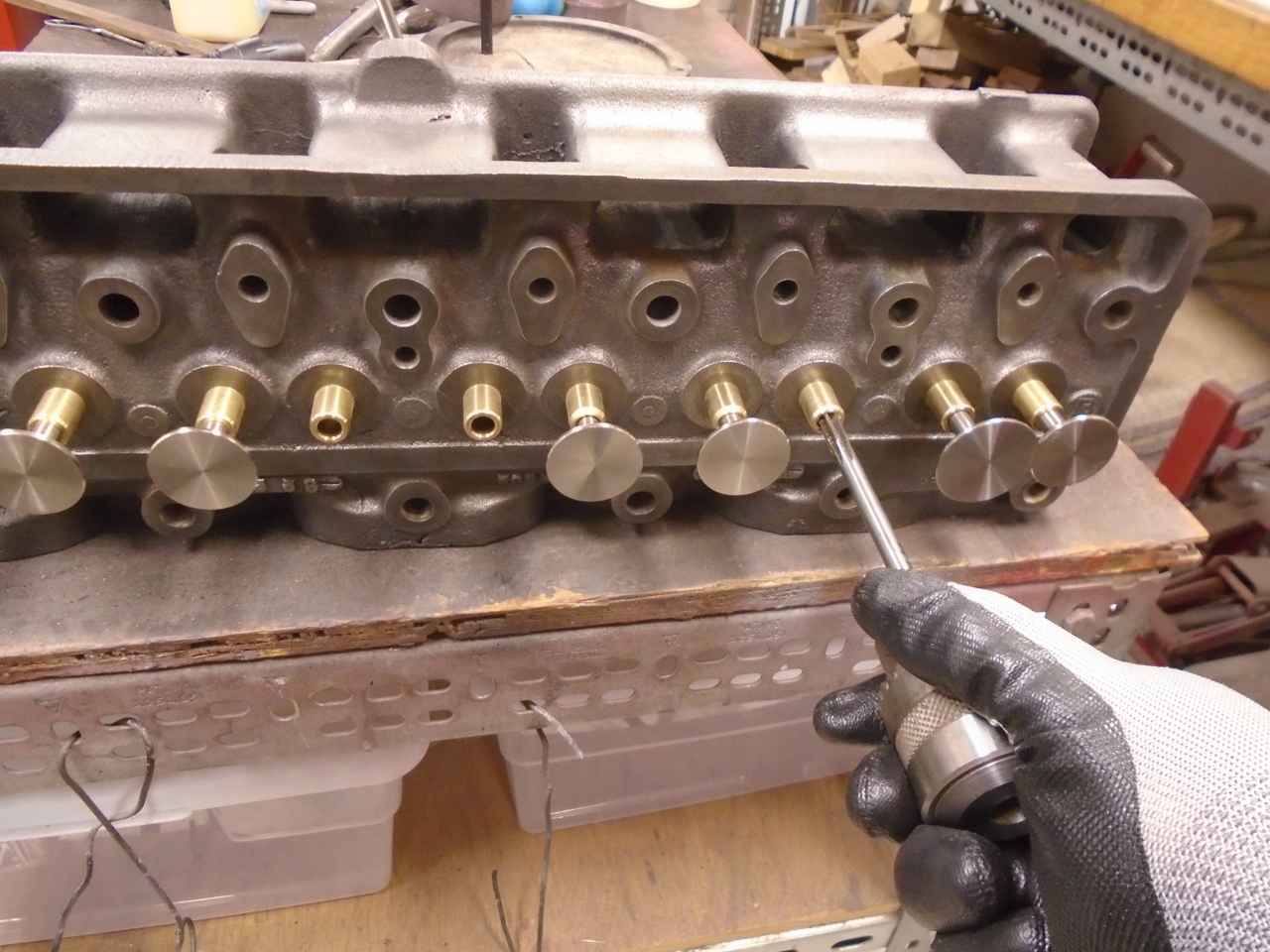

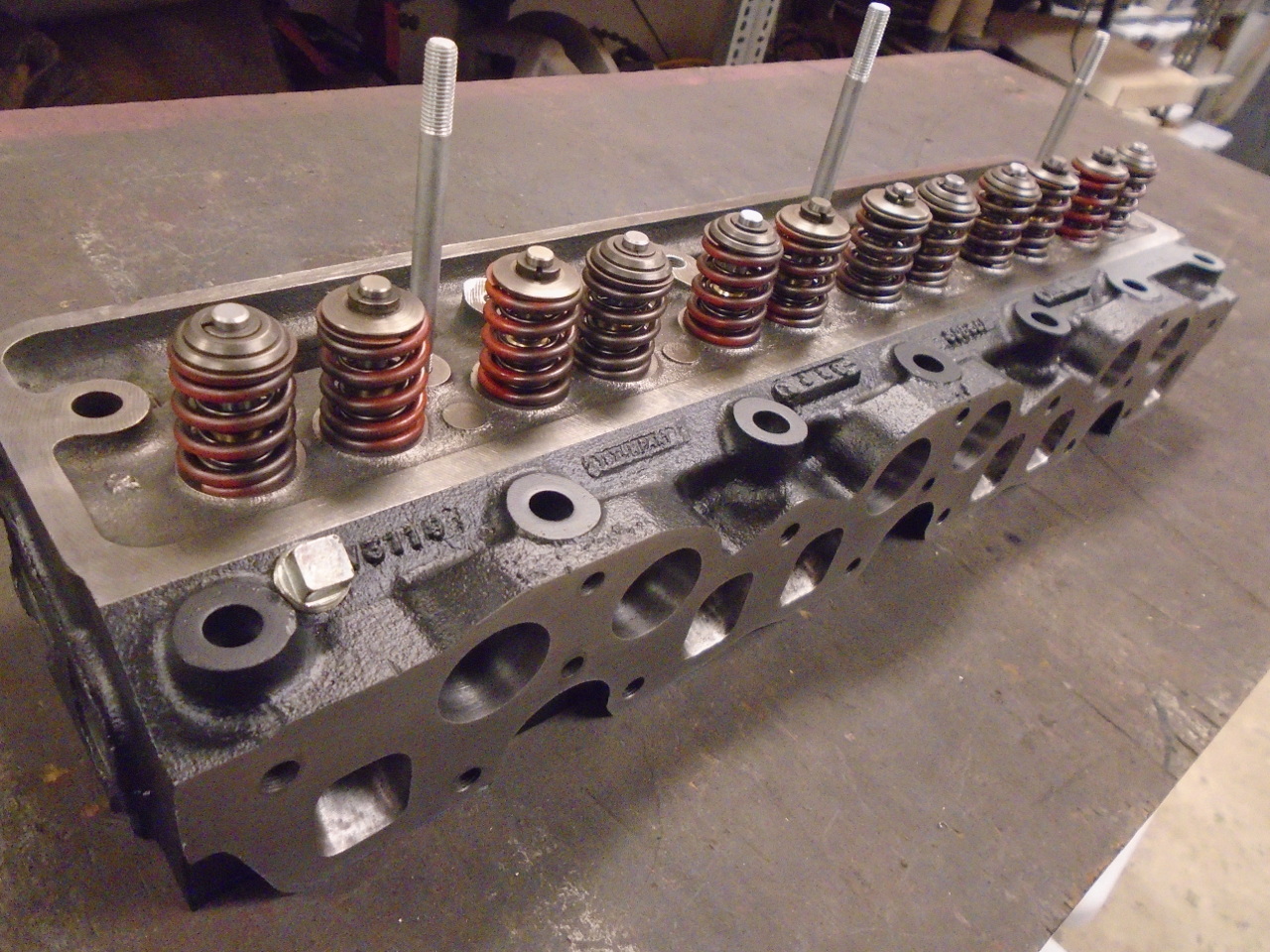

So, it was then time to get the head to the machine shop.

They would need the valve guides installed to to the seat

grinding. I opted for bronze guides because I like the

color.

I consider my Triumph Workshop Manual an indispensable resource,

but have learned that some of the specifications in it shouldn't

necessarily be regarded as gospel truth. For example, the

WSM lists the length of the valve guides as 2.72 inches.

The stock guides on my car were much shorter, and the intake and

exhaust were different lengths. The replacements I bought

matched the stock ones. Also, the protrusion of the guides

above the top of the head face is shown in the WSM to be

nominally 0.750", but my stock guides all had a protrusion of

about 0.630".

So, I departed from the WSM when I installed the guides.

The first pic shows the drift I used, and on the left, a collar

to limit how far the guides got pressed in.

Because of the valve stems being out of spec, I also ordered new

valves. The exhaust valves are stainless steel.

I checked the valve stems in the installed guides and found that

they were all very tight. I fixed this by hand reaming the

bores. Inexplicably, the inlet valve stems are about

0.001" larger than the exhaust stems (the WSM has this correct),

so it really needs two different sized reamers. The

closest I could come was a 0.3120" reamer for the exhausts, and

a 0.3125"for the intakes.

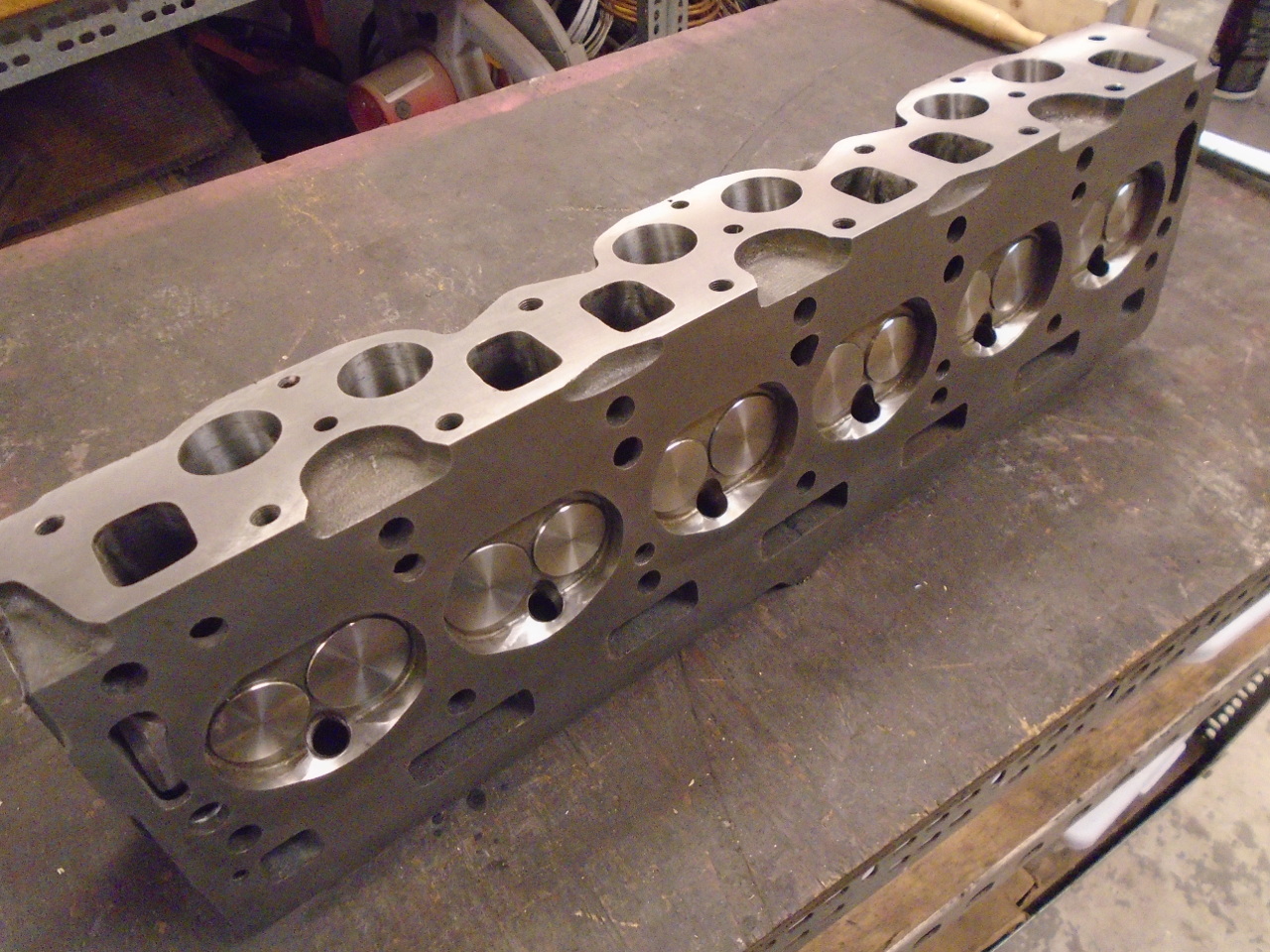

Then, it was off to the machine shop for the shaving and the

seat grinding. Turn around was really fast.

At this point, since I had all of the chamber "cc" stuff handy,

I checked all of the chambers. They were all within about

0.3 cc of the same volume, which is less than 1%. Since

this will be a street car, I didn't stress about the

variation. The new compression ratio calculated to be a

shade over 9.5:1.

The newly machined surface of the head looked really good.

Unfortunately, it made some of the other machined surfaces look

a little shabby by comparison. The manifold mating surface

had dings, scratches, and dents that were suddenly bothering

me.

Since it is a much narrower surface, and I've never tried it

before, I decided to face that side of the head.

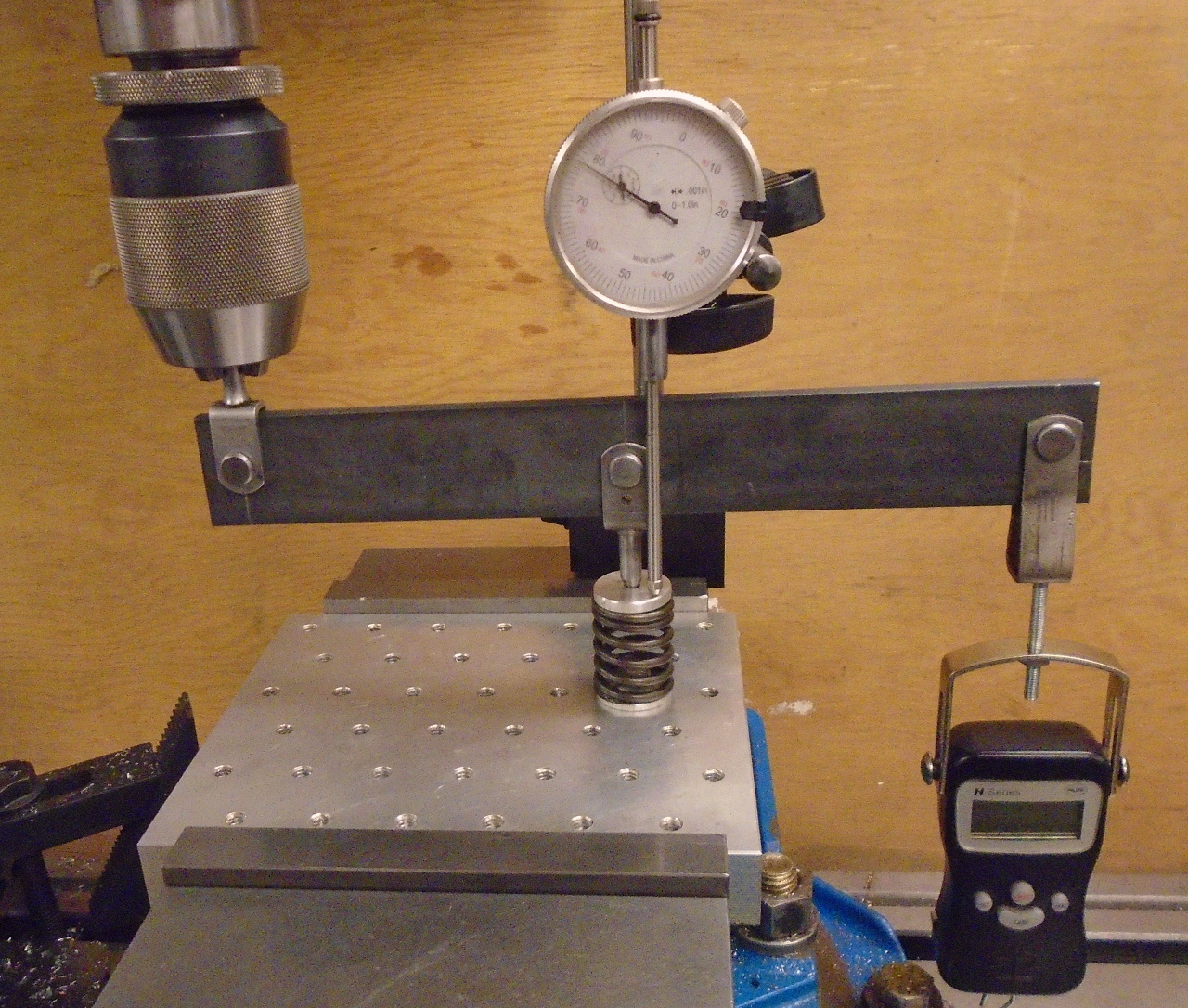

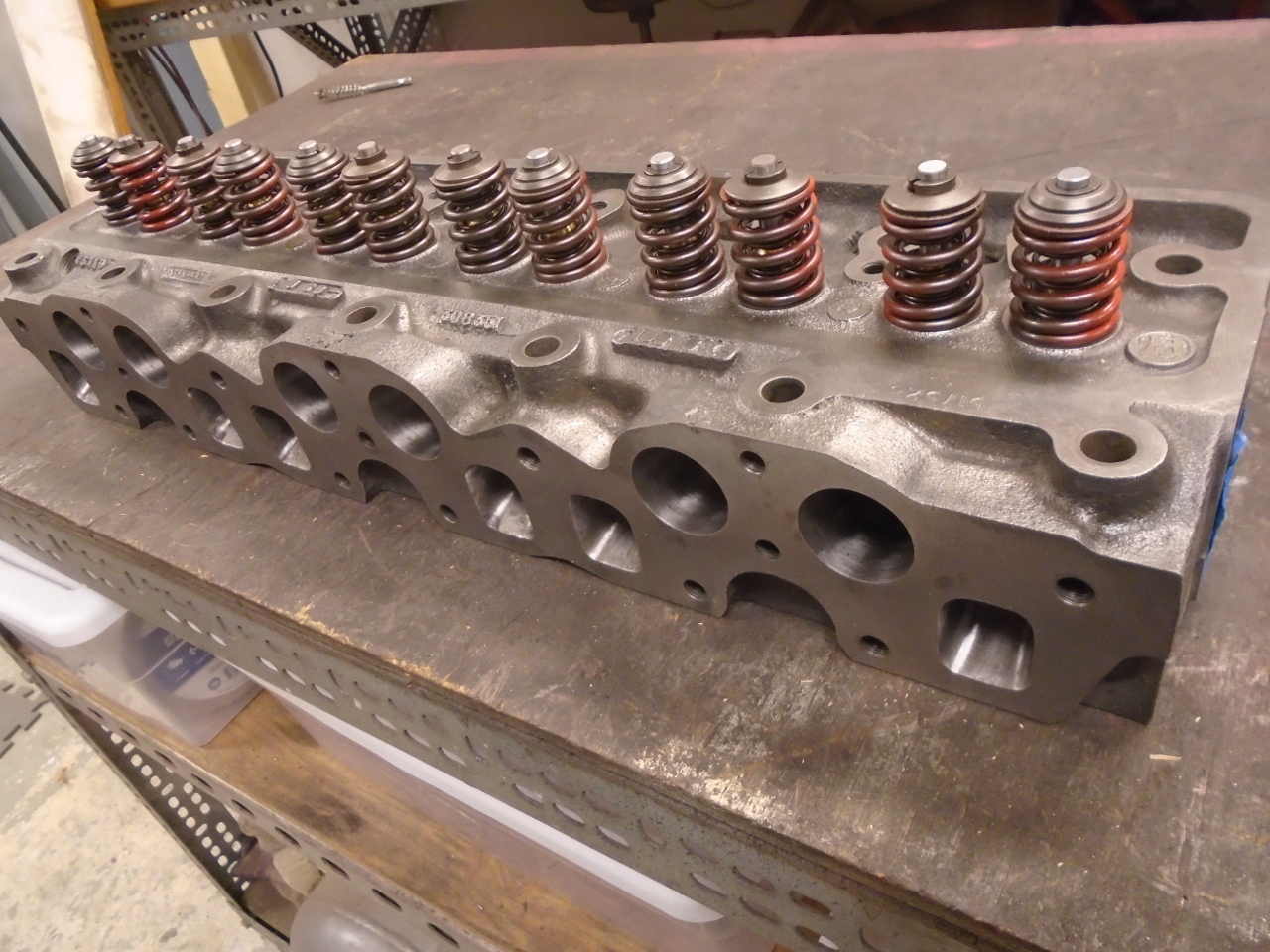

In anticipation of final assembly, I checked out the original

valve springs, and here is another place where the WSM let me

down. It appears that the WSM has the free length specs

for the inner and outer springs reversed, and the installed

length of the springs didn't match my head, either.

Looking past that, I measured the "seat" load of the springs,

using an impromptu lever arrangement.

Given the unreliable length specs, it was a little hard to know

what the load really should be, but I concluded that the

measured load was low for both the inner and outer

springs. So I ordered new springs. The new springs

will offer quite a bit higher load than the old springs.

Total seat load form both springs will be about 50 pounds.

This is still low my modern standards, but about 13% above the

WSM spec. Most of the extra load comes from the new outer

spring, which has thicker wire and fewer coils than the original

spring (and is wound the opposite way, oddly).

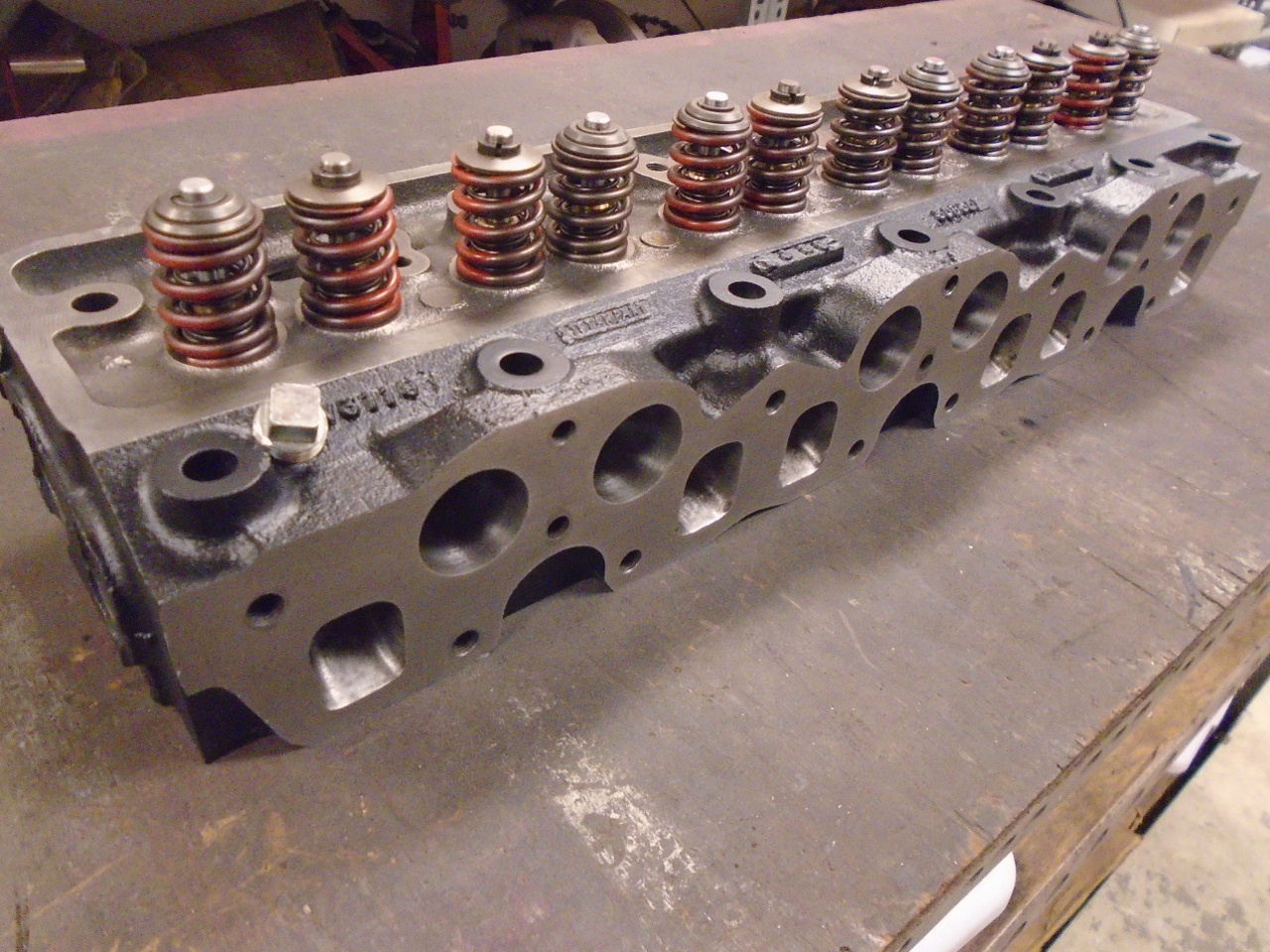

So, assembly time, but first, lap the valves. This ensures

a tight seal.

There are over a hundred parts here...

...but they all found a home.

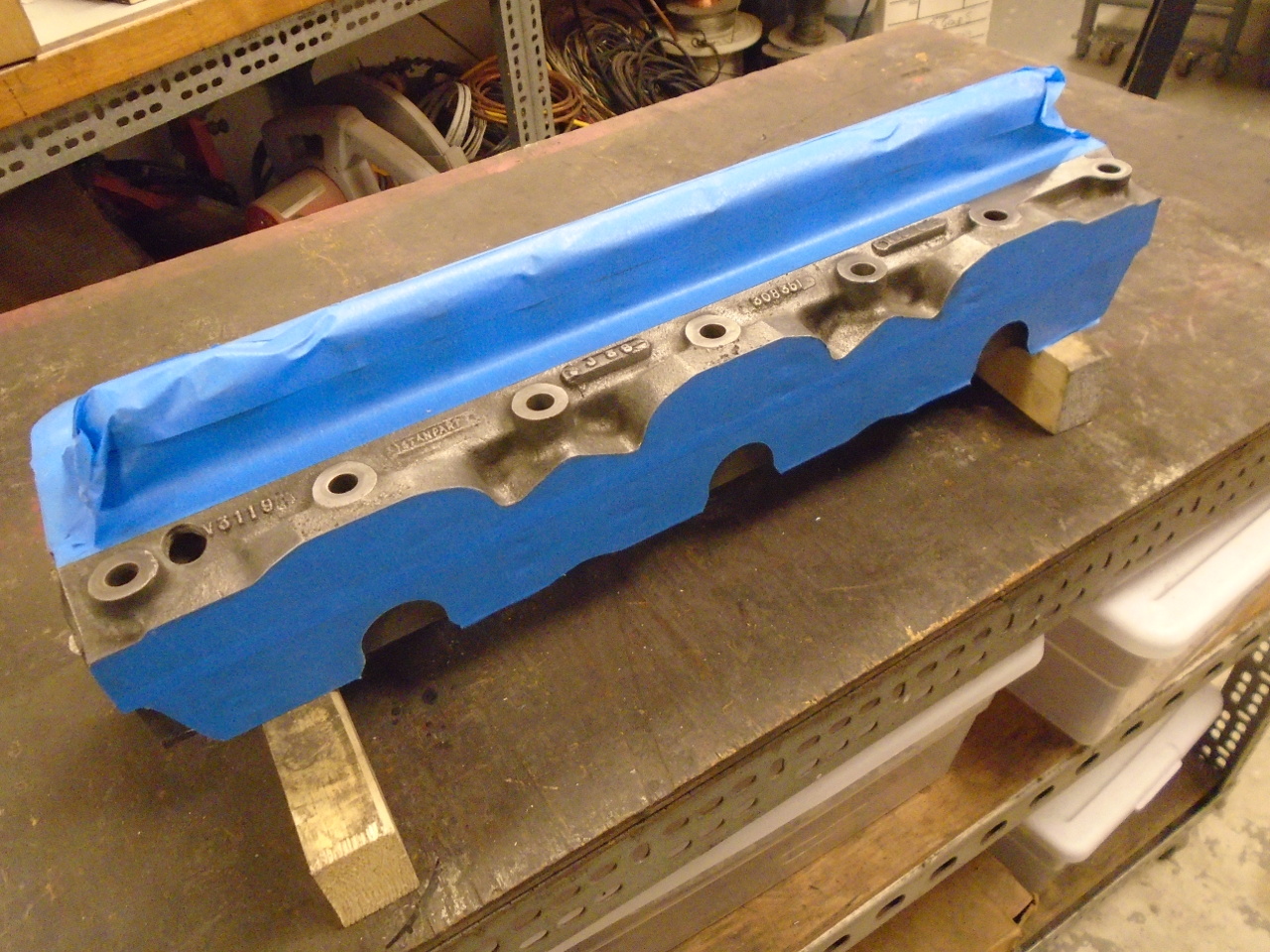

And some paint to make her look pretty.

One of the three valve cover studs had long ago been replaced by

a long bolt, so this was my chance to make it right.

And then to take care of a couple of details that I almost

surely would space off before first startup.

On the shelf until I'm ready for it.

A lot of steps in this project, and a lot of repetition.

Also, one of the more expensive ones at around $350 for the

valves, springs, guides, and the machine work. Can't wait

to install it.

Comments to Ed at elhollin1@yahoo.com

To my other GT6

pages