To my other GT6 pages

March 26, 2023

Luggage Floor

The GT6 roof

is of a "fastback" design, which features a smooth uninterrupted flow

from the top of the windscreen to the tail of the car. This design

doesn't offer a traditional boot or trunk, but rather a continuous open

cabin that extends to the rear end of the car. In the GT6, the lower part of

this rear space is occupied by the fuel tank and the spare tire

compartment, and these utility spaces are covered by panels that form

the floor of the rear stowage space, apparently called by the factory

the "luggage floor".

The luggage floor in this car consisted of three panels, each made of a

hardboard material of nominal 1/4" thickness. There are two aft

panels, the left of which is fixed over the fuel tank. The right

rear panel is removable, and covers the spare tire well. these

panels are supported at their forward edges by a crossmember.

There is also a fixed forward panel that spans the car from side to

side, and is supported by the same crossmember at its rear, and another

crossmember at its front.

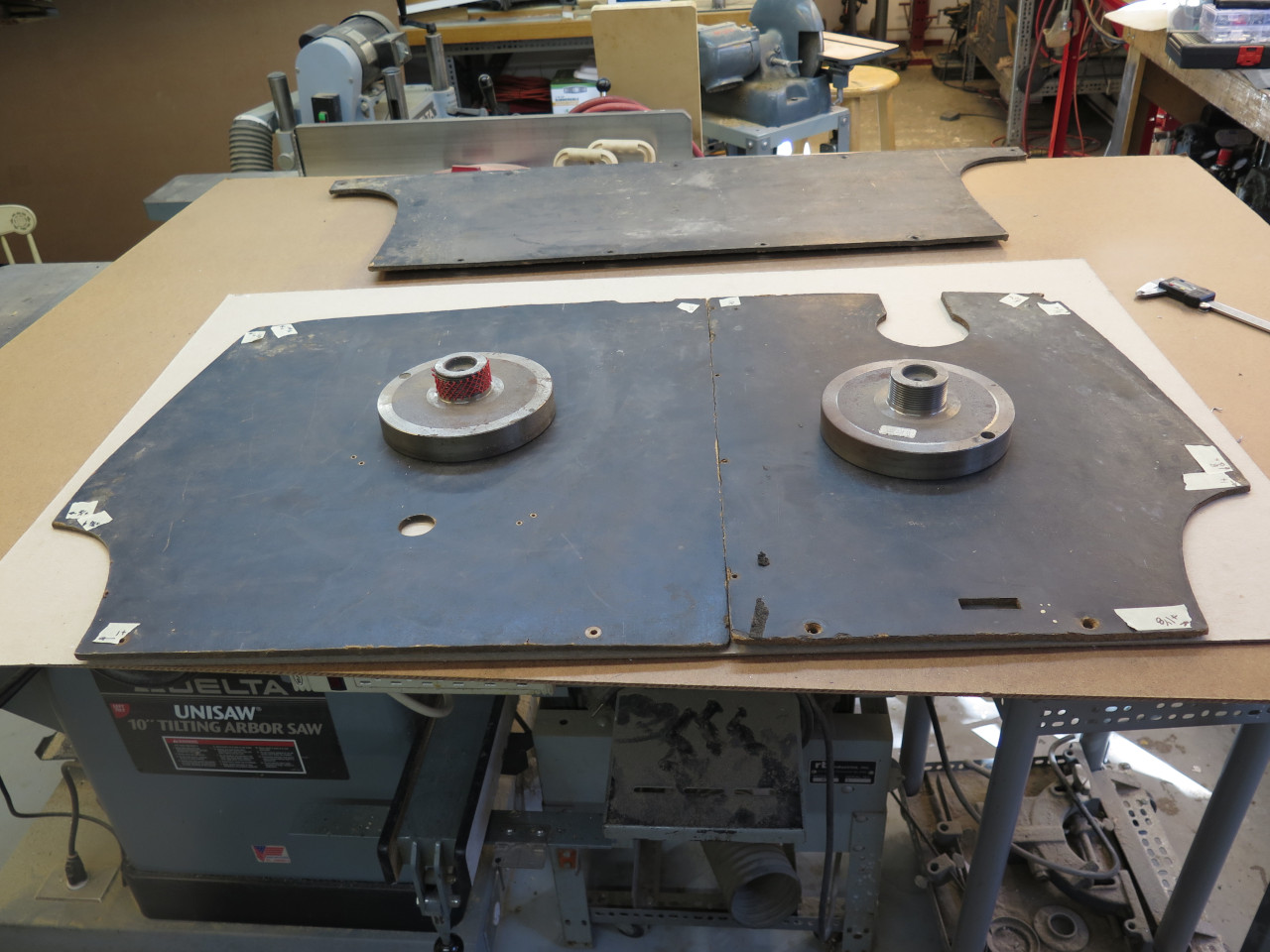

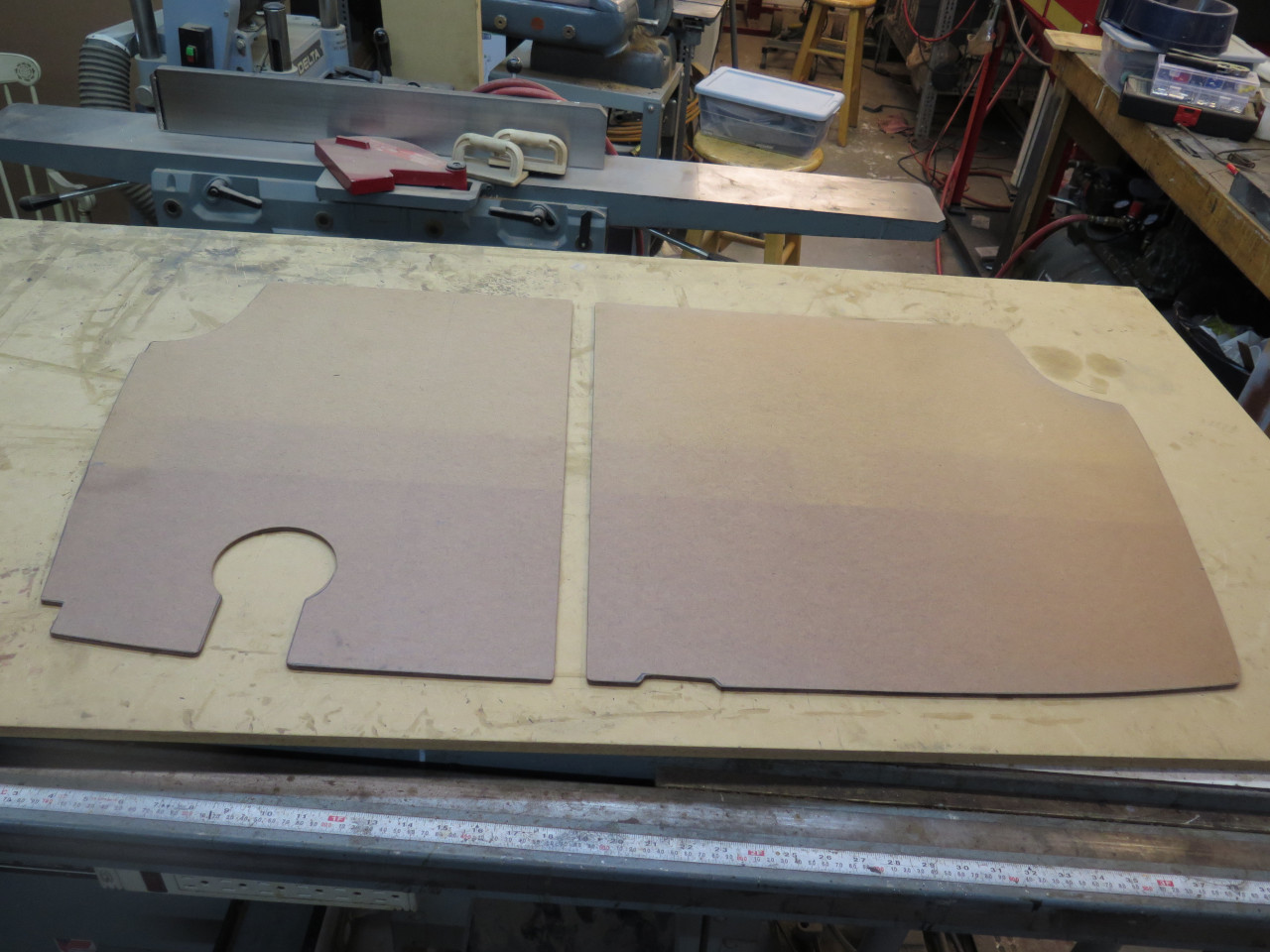

These are the original rear panels. The odd-shaped cutout in the left one is to accommodate the fuel filler neck.

The original panels were beat up, dirty, and frayed at the edges and around the mounting holes.

And they also didn't fit the car very well. There were

considerable gaps around all of the edges. I thought new panels

would be an improvement, but since they are apparently not available

anywhere, they became a project.

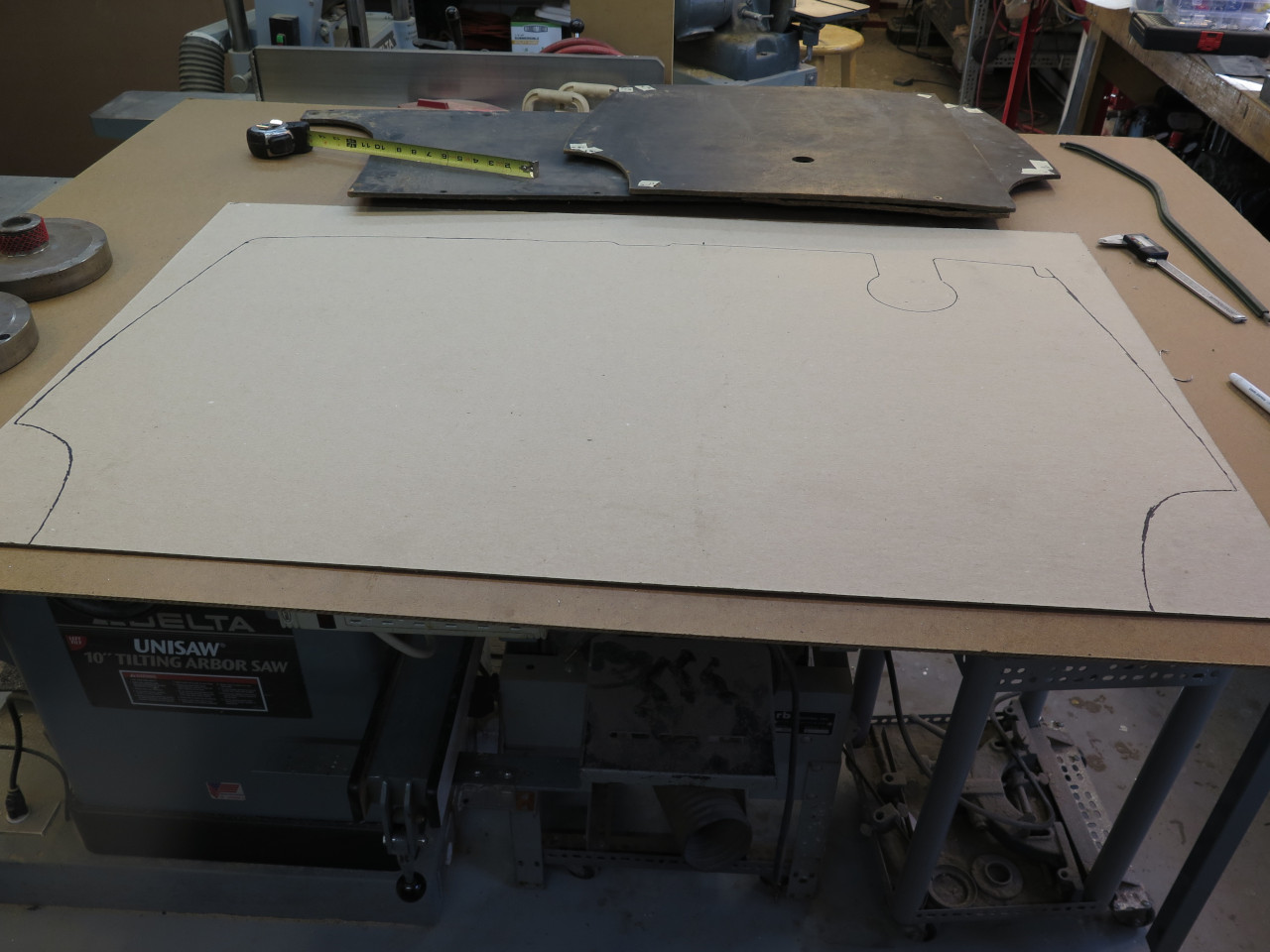

First task was to make patterns that fit better. I marked the gap sizes on the originals.

Then transferred the shape, including corrections for better fit to some

chip board as a pattern. I did the two rear panels temporarily as

a single piece.

I test fit the new pattern in the car. After a few corrections here and there, it finally fit pretty well.

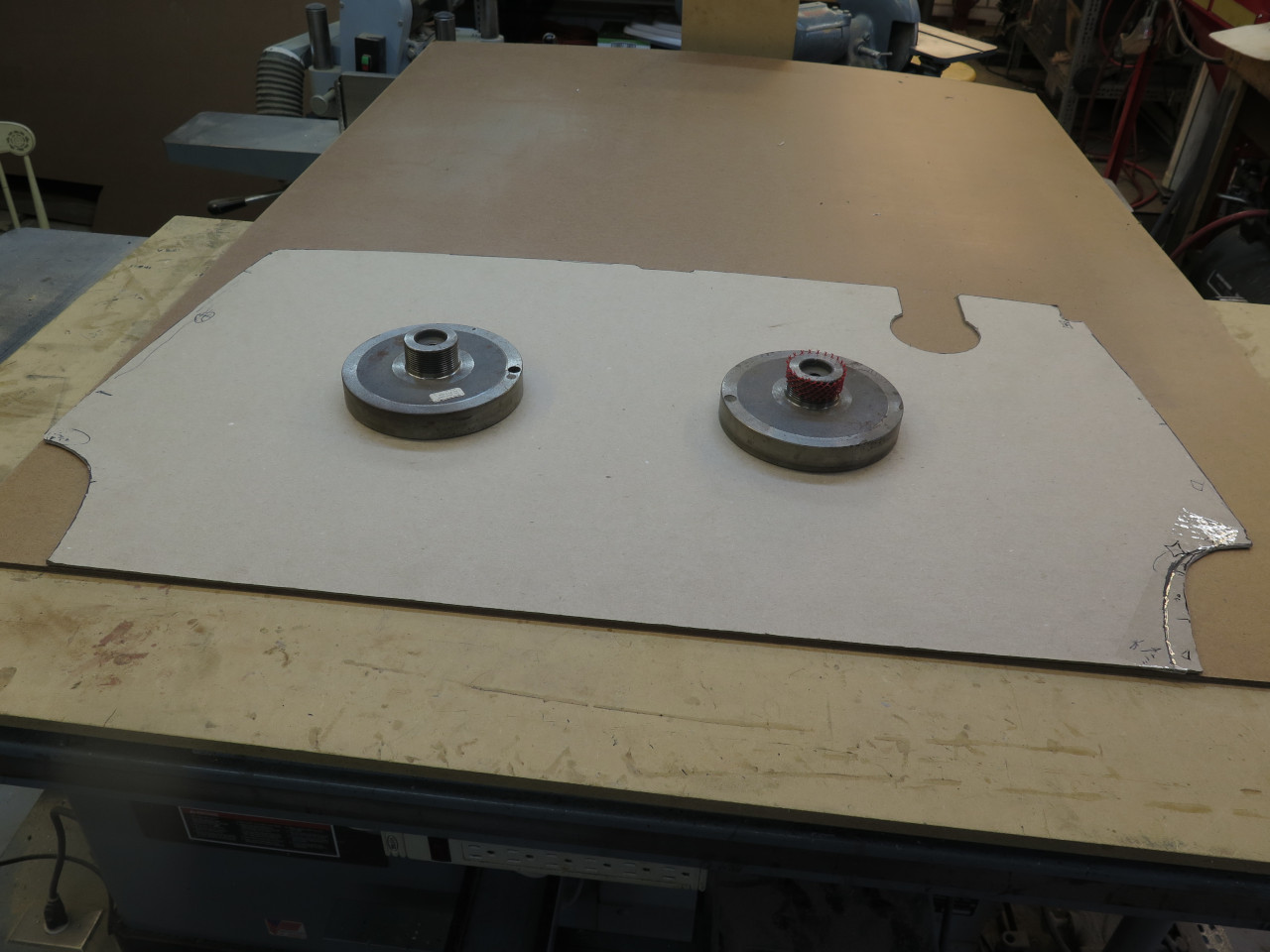

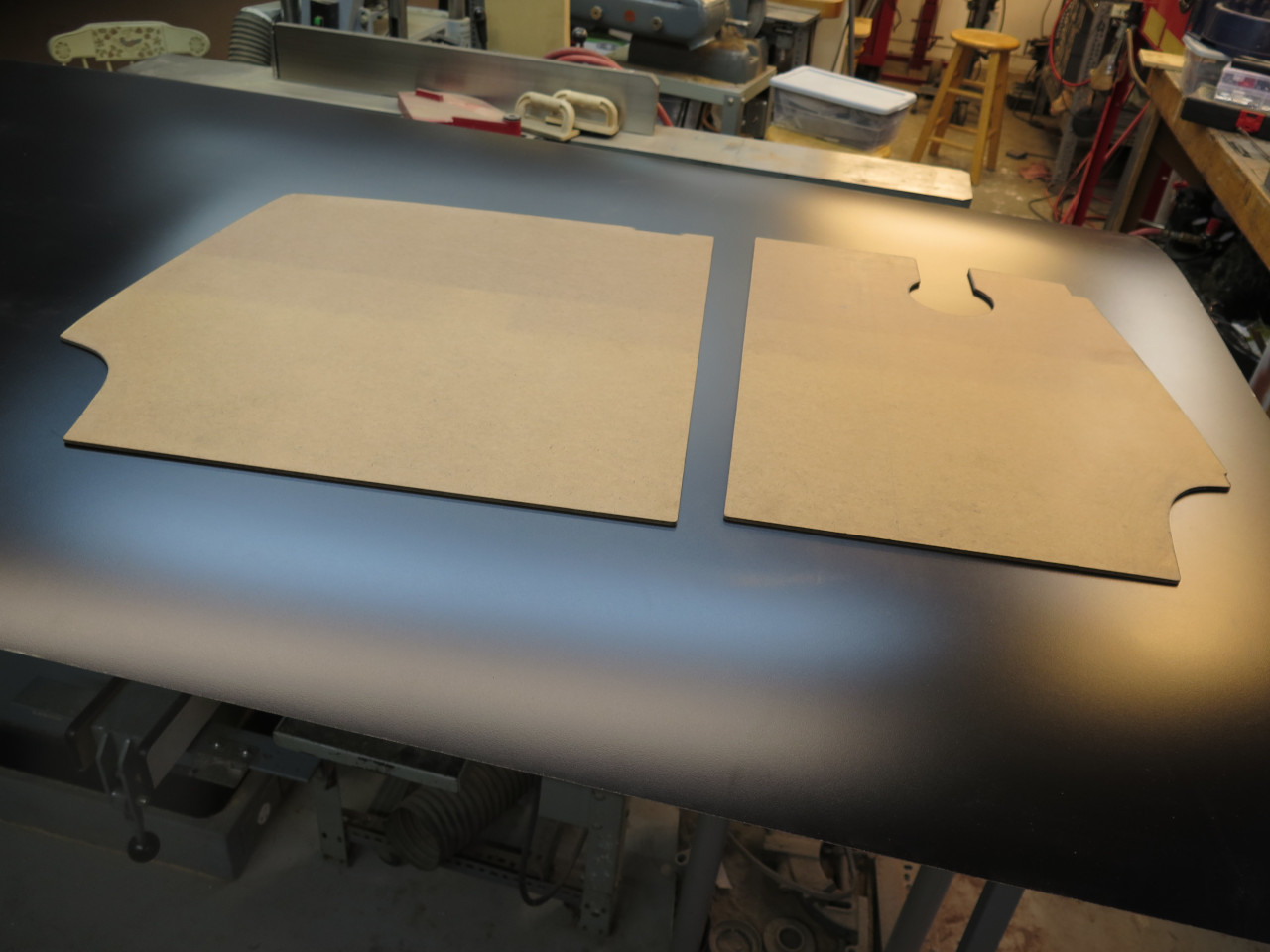

Then transferred the pattern to some new hardboard. It's not easy

to get actual 1/4" hardboard these days. This stuff is advertised

as 3/16", but it's actually only about 0.160", so probably manufactured

as 4 mm.

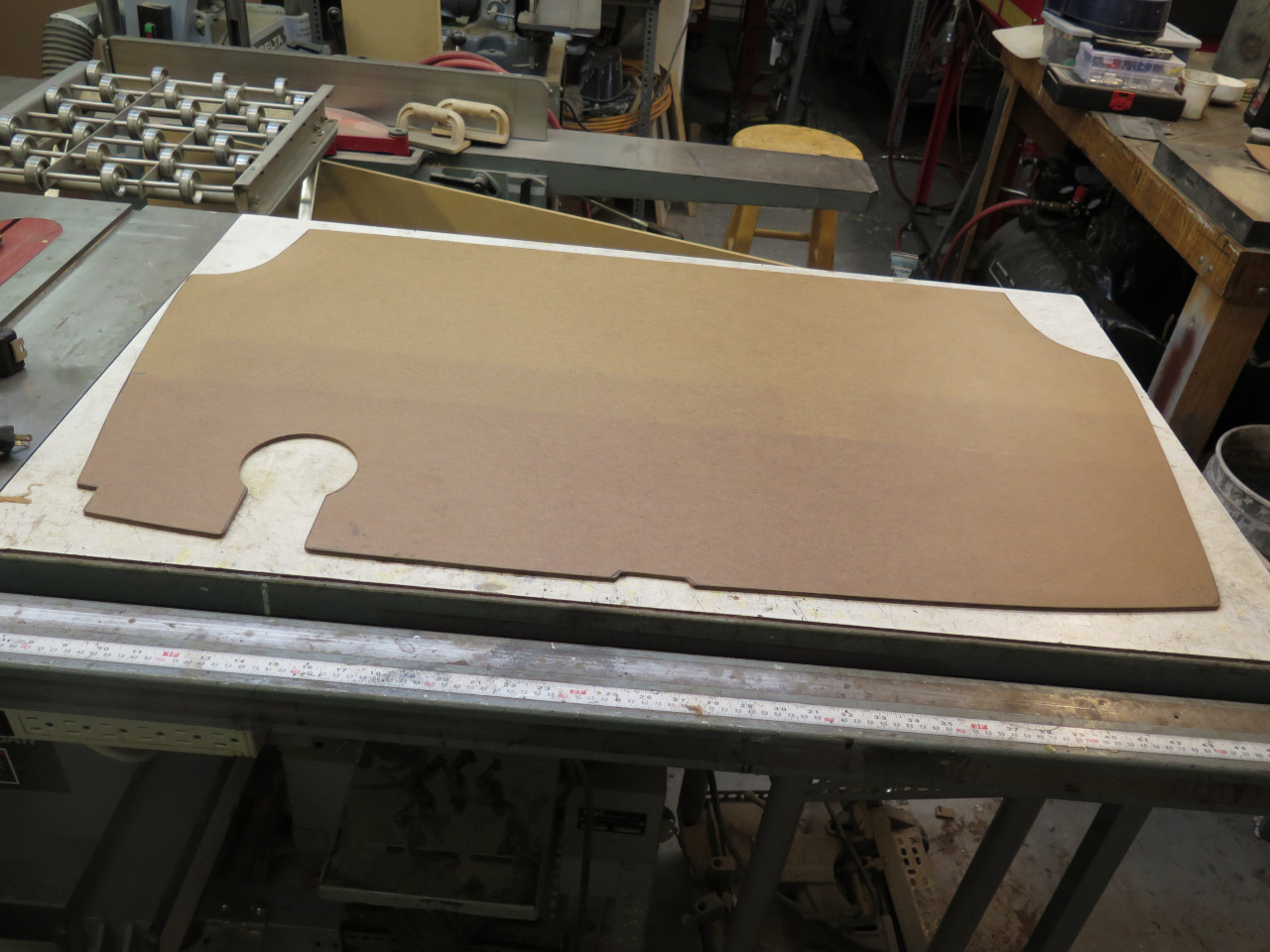

I brought the front panel to the same stage and test fit them both in the car.

The rear panels were then separated with a straight saw cut.

The reason I wasn't too concerned about the thickness of the hardboard

is because I planned to cover both sides with a plastic laminate.

This is Formica brand, but there are others.

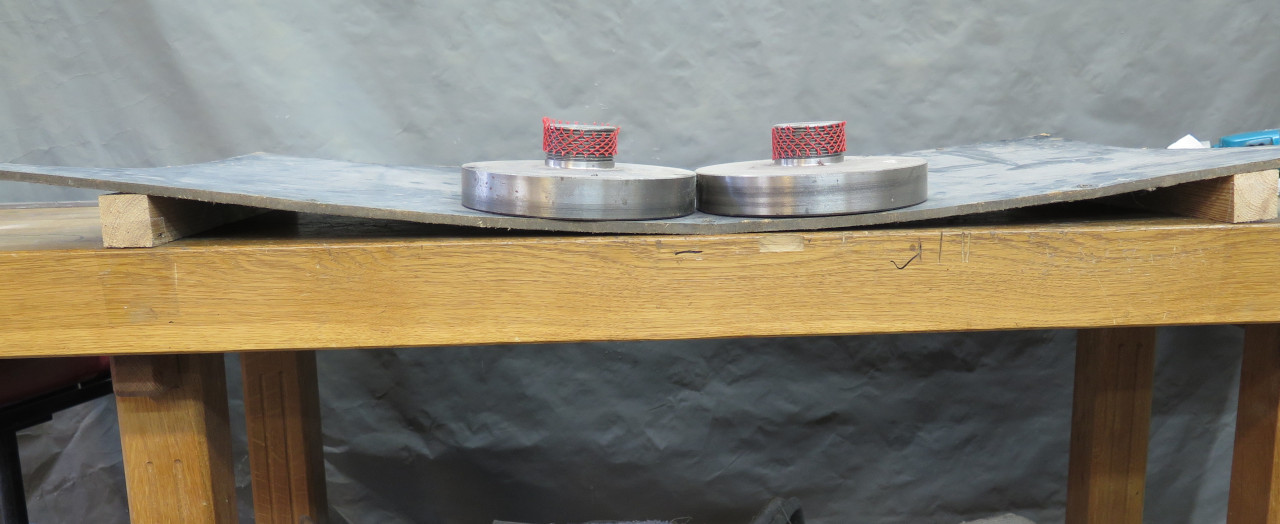

The laminated panels measure at about 0.220", which is still a little

thinner than the originals, but in handling them, they seemed stiffer

than the originals. Concerned that this may have been just some

confirmation bias talking, I decided to do some science. I set up

some supports 30 inches apart, so that the front panel would fit nicely

across them. I then placed 20 pounds of weight in the center of

the span, and measured the deflection. The original panel

deflected the full 1.5 inches to the table, and might have gone a little

further. The new laminated panel deflected a little over

0.5". This tells me that the new panels are around three times

stiffer than the originals. It is possible that the old panels

were stiffer when new.

This made me happy, so I pressed on in preparing the panels for installation.

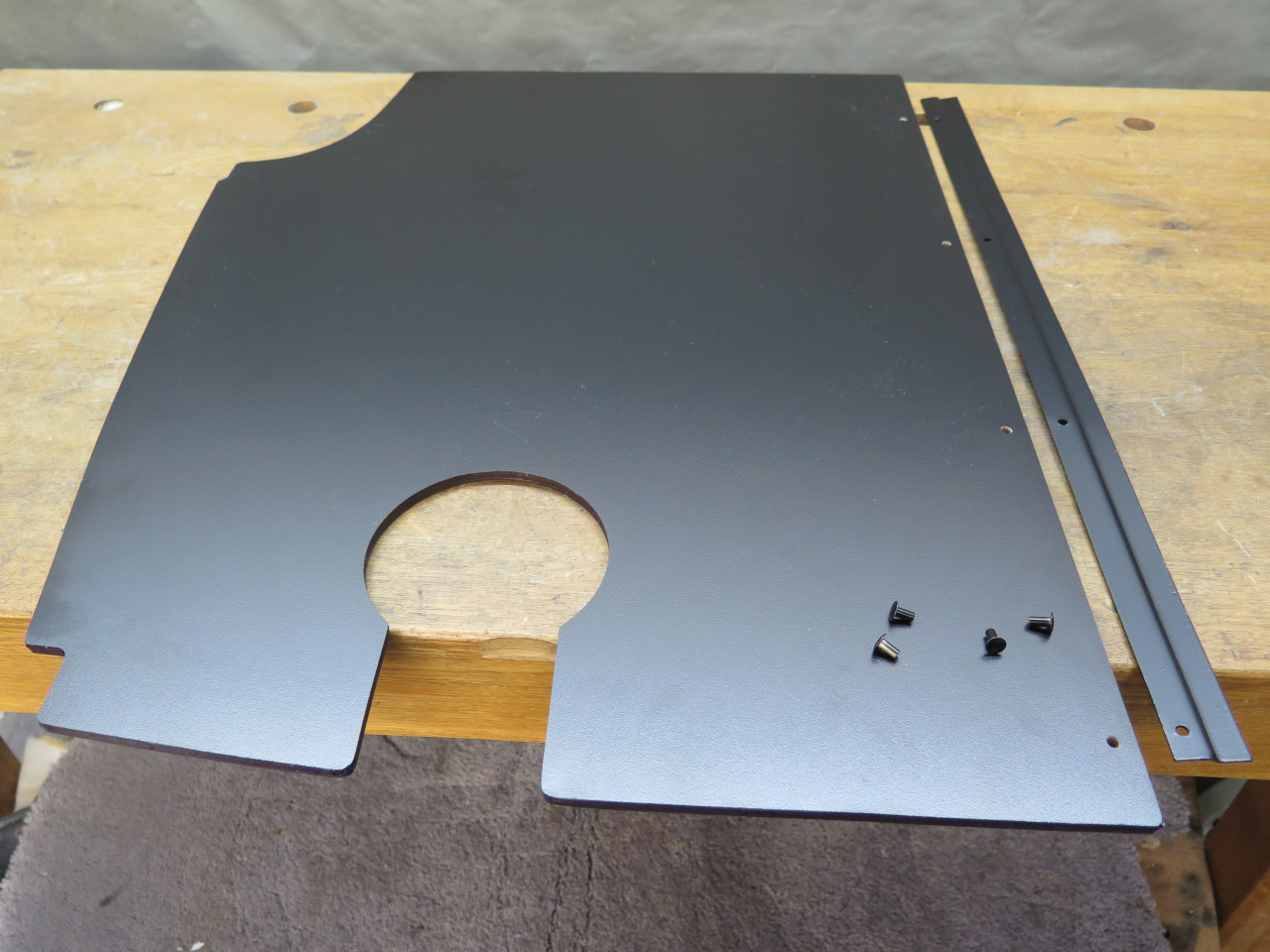

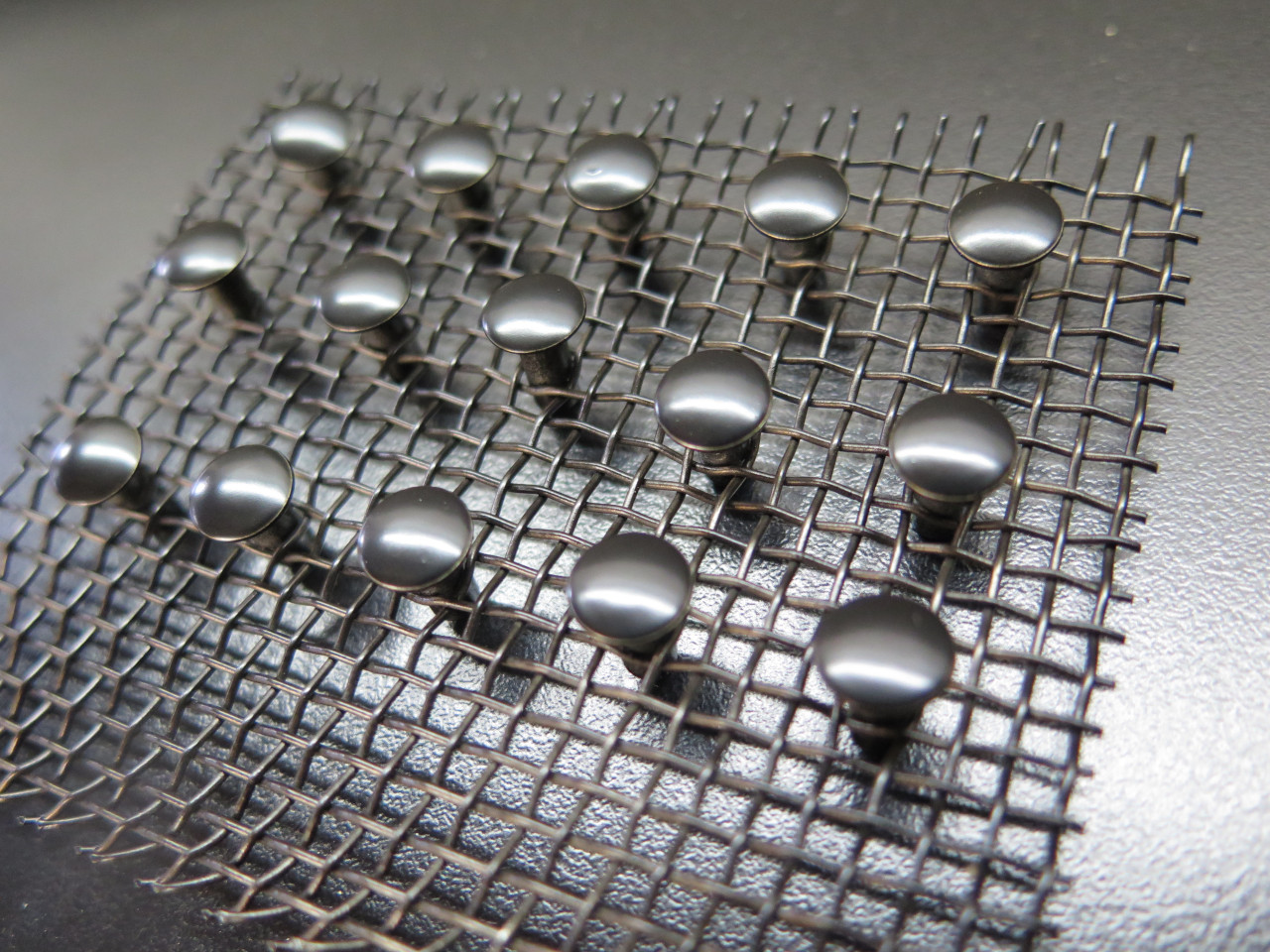

The fuel tank cover gets a stepped metal strip riveted to its inboard

edge. This strip serves as a flange for the removable spare tire

cover panel to rest on. Rivets were standard semi-tubular type,

but I powder coated the heads to duplicate the originals.

The bottom side of the panel is very close to the fuel tank, so to

prevent rattles and to provide some support, there were felt strips

glued to the underside. The support strip also gets a felt layer.

For a time, I was baffled as to why the outboard edge of the fuel tank

cover appeared to be unsupported. I finally realized I was missing

a part. Rummaging through he shed, I finally came up with

it. Maybe this support flange had to be removable to get the gas

tank in and out.

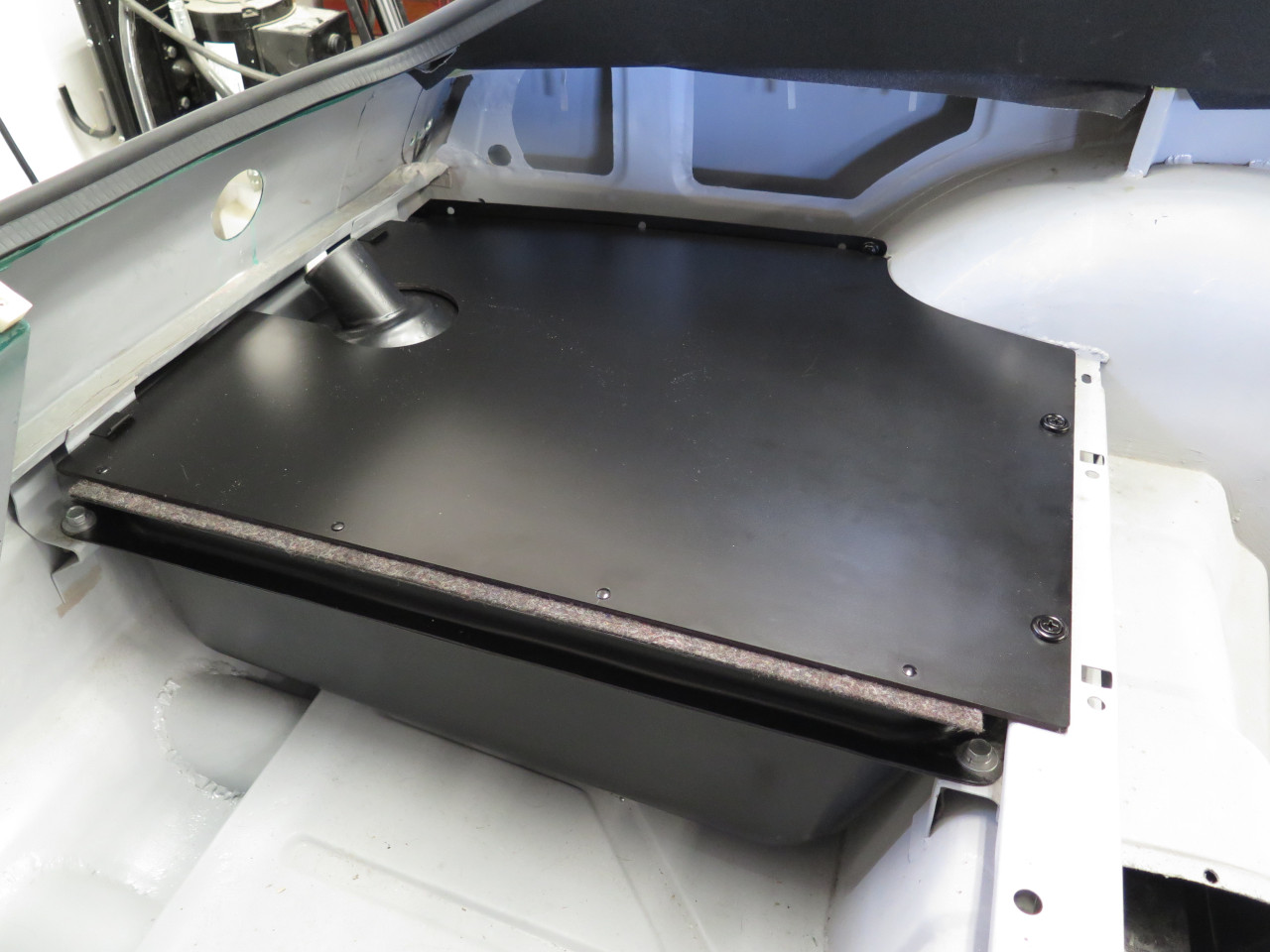

Then took the panel home. I discovered just before installing it

that it also needed felt strips on its mounting surfaces around the

perimeter except at the rear edge, so I added those. I used some

largish powder coated finish washers around the fasteners to spread the

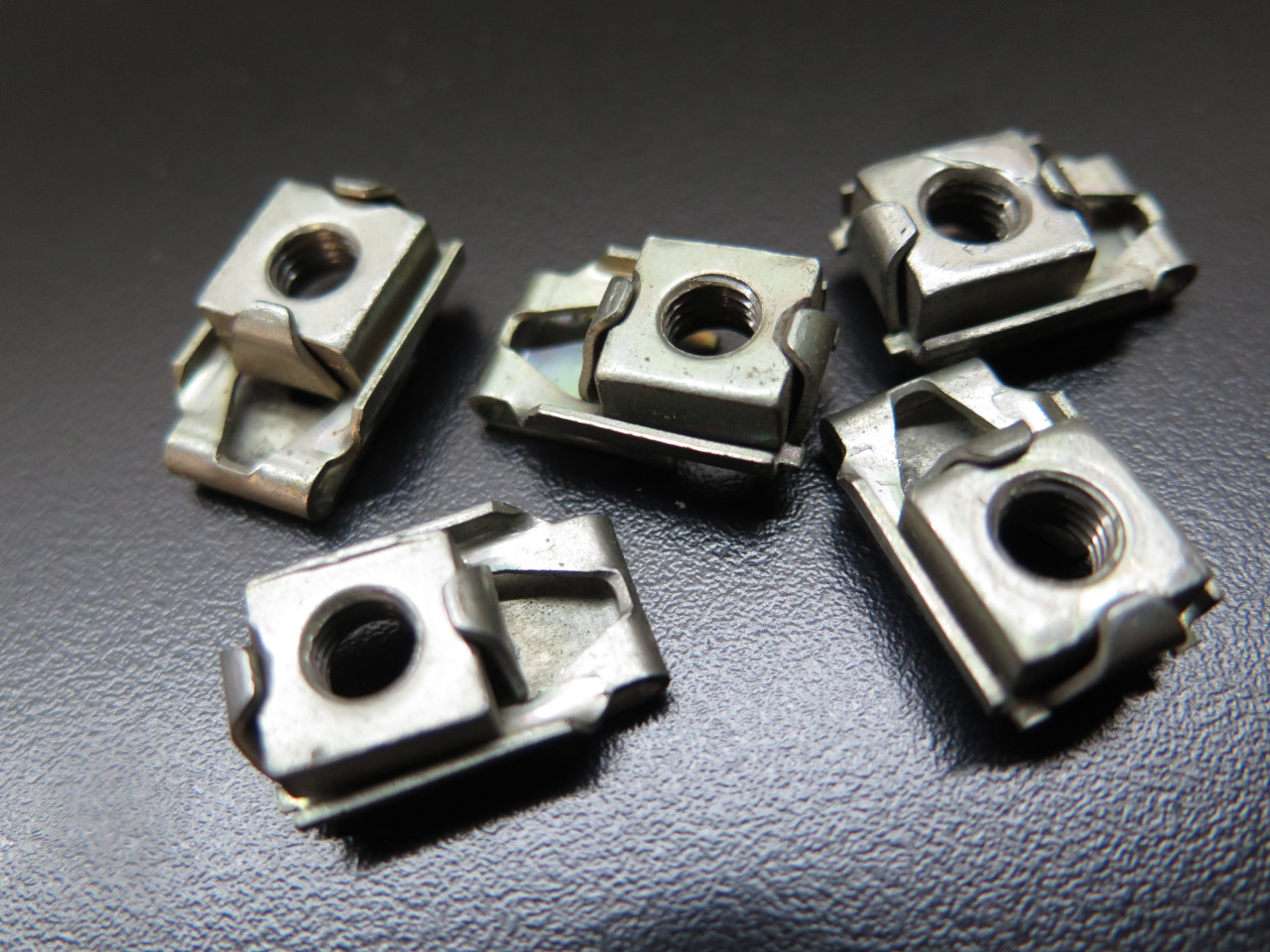

stress. Right most image shows the spring nuts that go in the

crossmember.

The spare tire cover also has various attachments. A couple of

spring clips are riveted on to hold the crank handle for the jack, and

there are the "spire studs" that go on the leading edge to mate with

spring latches in the crossmember, holding the panel in

place. The pic on the right shows the spring latches.

One thing of note on the spire studs: What appears to be 8-32

fasteners are actually British 2BA. The Brits do like their odd

ball threads.

There is a finger hole in the panel to allow for removing the

panel. I thought it a nice touch to provide a little finish ring

to the hole. This one is 3D printed (after three previous

iterations that didn't look right or fit snugly).

Felt around the edges to stop rattles.

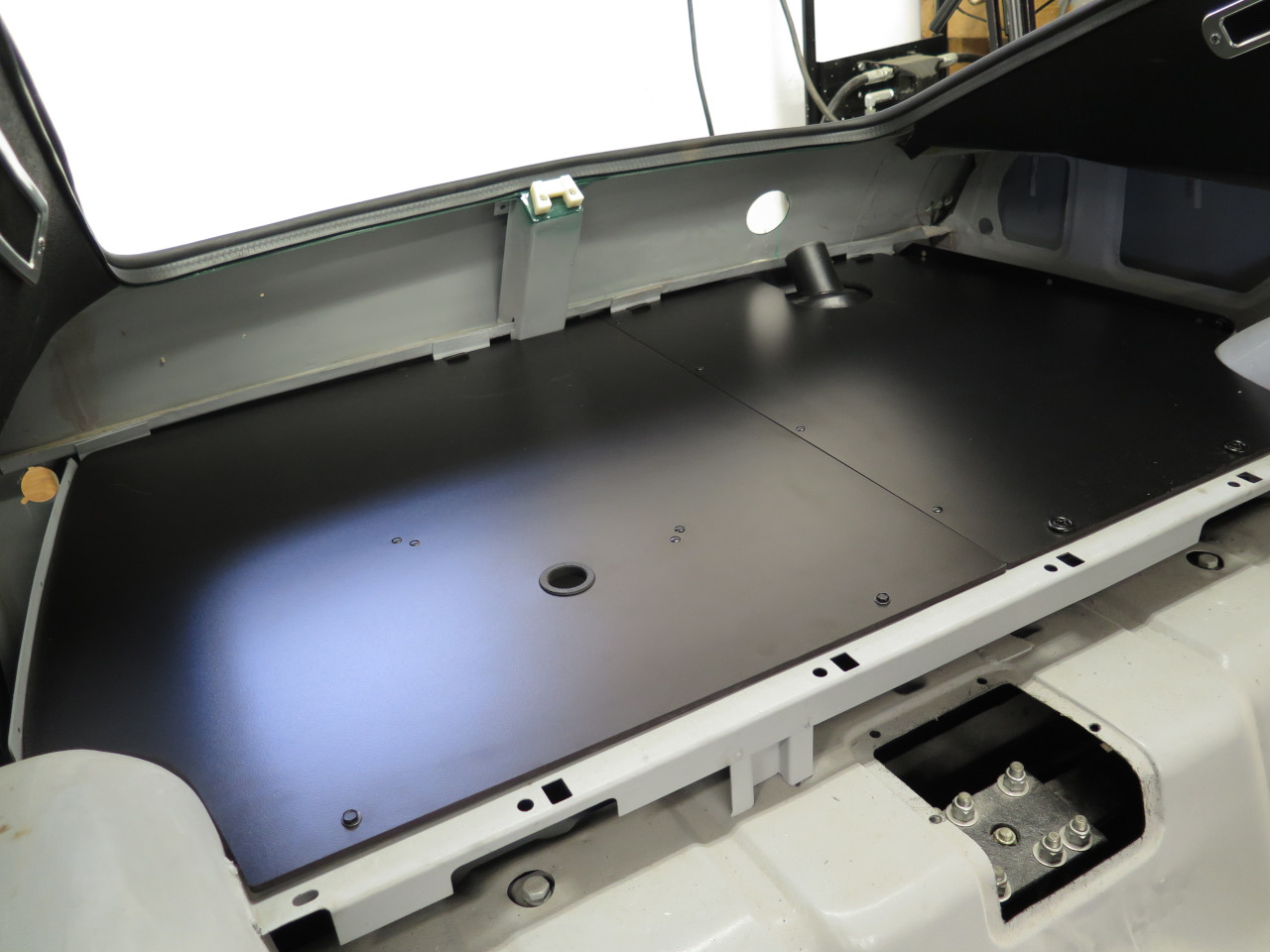

The two rear panels installed. There are some spring clips that hold the trailing edges of the panels in place.

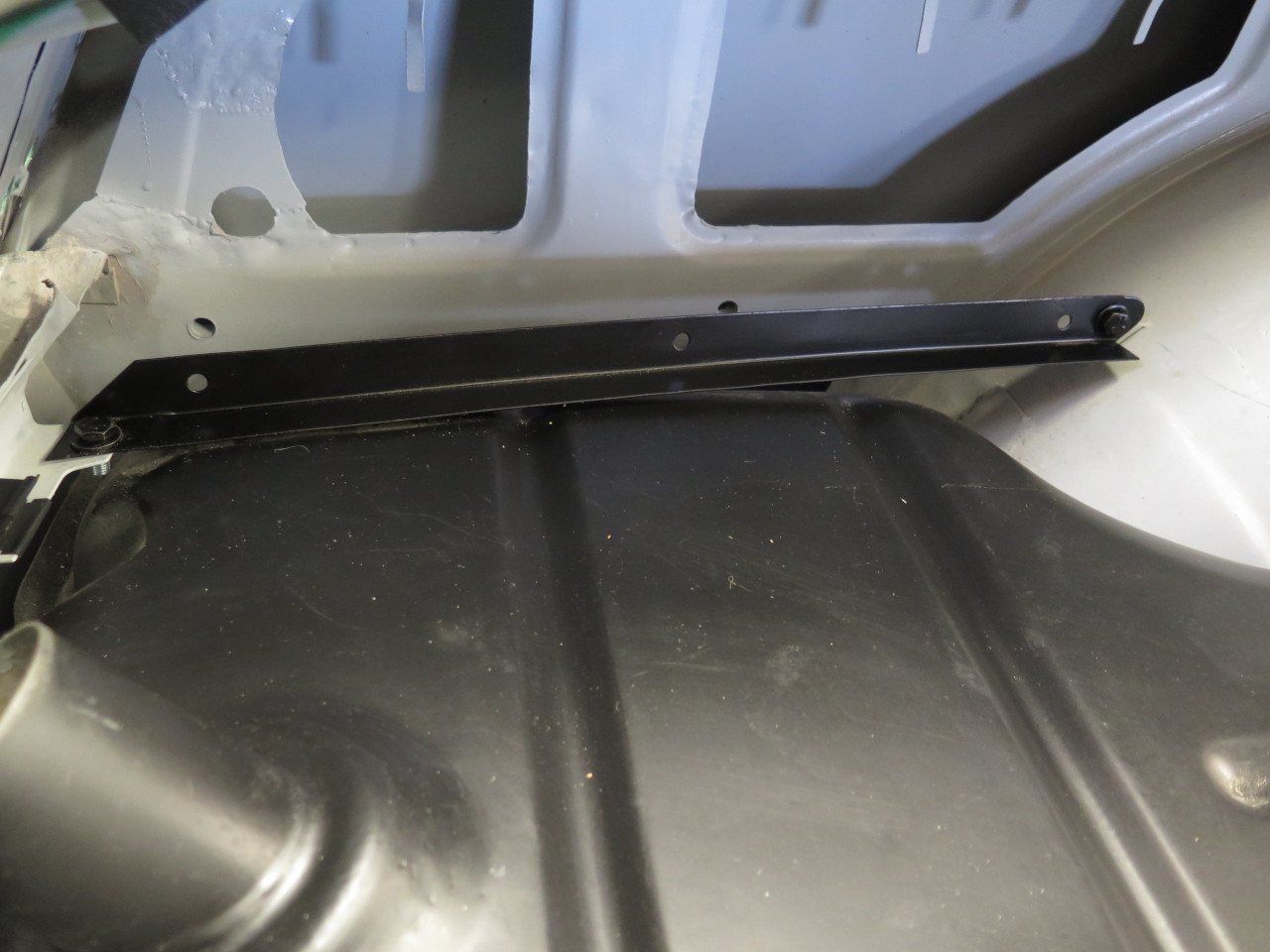

The forward edge of the front panel is supported by a removable

crossmember. This was originally just a sheet metal angle, and

when I got the car decades ago, this piece was buckled. I replaced

it at that time with a much beefier chunk of proper angle iron. I

believe the original angle was installed such that the vertical flange

of the angle was turned down, but I thought at the time that it would be

more useful if the vertical side were turned up to serve as a lip on

the forward edge of the floor. This might keep things from rolling

off. All of this still seemed like a good idea, so I decided to

keep it.

While I was at it, I decided to also add a couple of additional support

struts for the front panel that would bridge between the two

crossmembers.

For some reason, the original front panel didn't use felt on its

supports like the other panels did. I added some anyway.

And finally took it home. The result is a deck that is much

sturdier and much more durable than the original. An "upgrade", I

guess.

This little project took a while, and these panels were a little awkward

to repeatedly install and remove, mainly because they fit so much

tighter than the originals. I like it when a project makes a

relatively large scale visible difference, though. This all has to

come out again, along with the fuel tank because I want to paint the

spare tire well BRG. Should have done this earlier.

Cost of this little passtime was around $100, mainly for the laminate and hardboard.

Comments to Ed at elhollin1@yahoo.com.

To my other GT6 pages