To my other GT6 pages

December 26, 2022

Door & Wheel Arch Cards

The interiors of Triumph cars of this era were generally pretty

utilitarian, maybe even spartan. Spanning from the A post to the

rear of the car, the door cards and the wheel arch panels were covered

with thin vinyl over some token padding. The base of both panels

was simple 1/8" flat hardboard.

The door cards did have a lower panel of some sort of fuzzy material

that probably did look sort of nice when it was new. There were

also some heat-welded lines, apparently intended to look like stitched

channels or pleats, but I don't think it ever really fooled anybody.

My door cards didn't look very good.

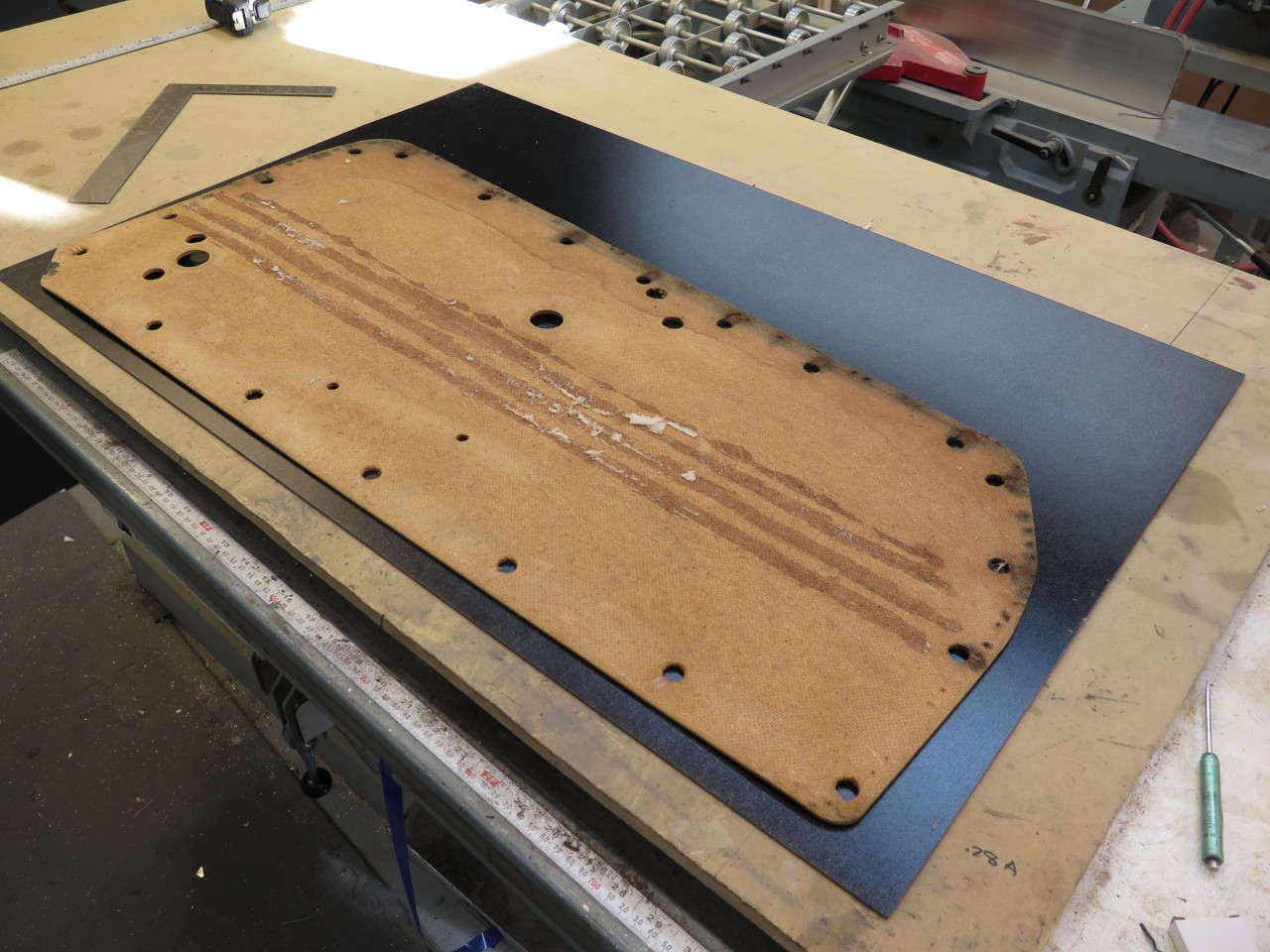

One of my cards had a layer of plastic attached to the backside. I

believe there was originally some "water curtains" in the doors to try

to keep water away from the cards, but I don't think this was the

original curtain. There were signs of significant water damage on

both cards. It looked like wet debris had gotten trapped between

the door and card.

The vinyl cover was attached to the card by the heat welds across the

center, and by staples around the perimeter. The foam padding was

barely 1/8" thick, and had gotten sort of stiff.

Because of the potential exposure to water, even with water curtains,

I've always thought that hardboard is not the best material for this

application. I know that some folks have used aluminum with

success, but I thought that some sort of plastic sheet would also work

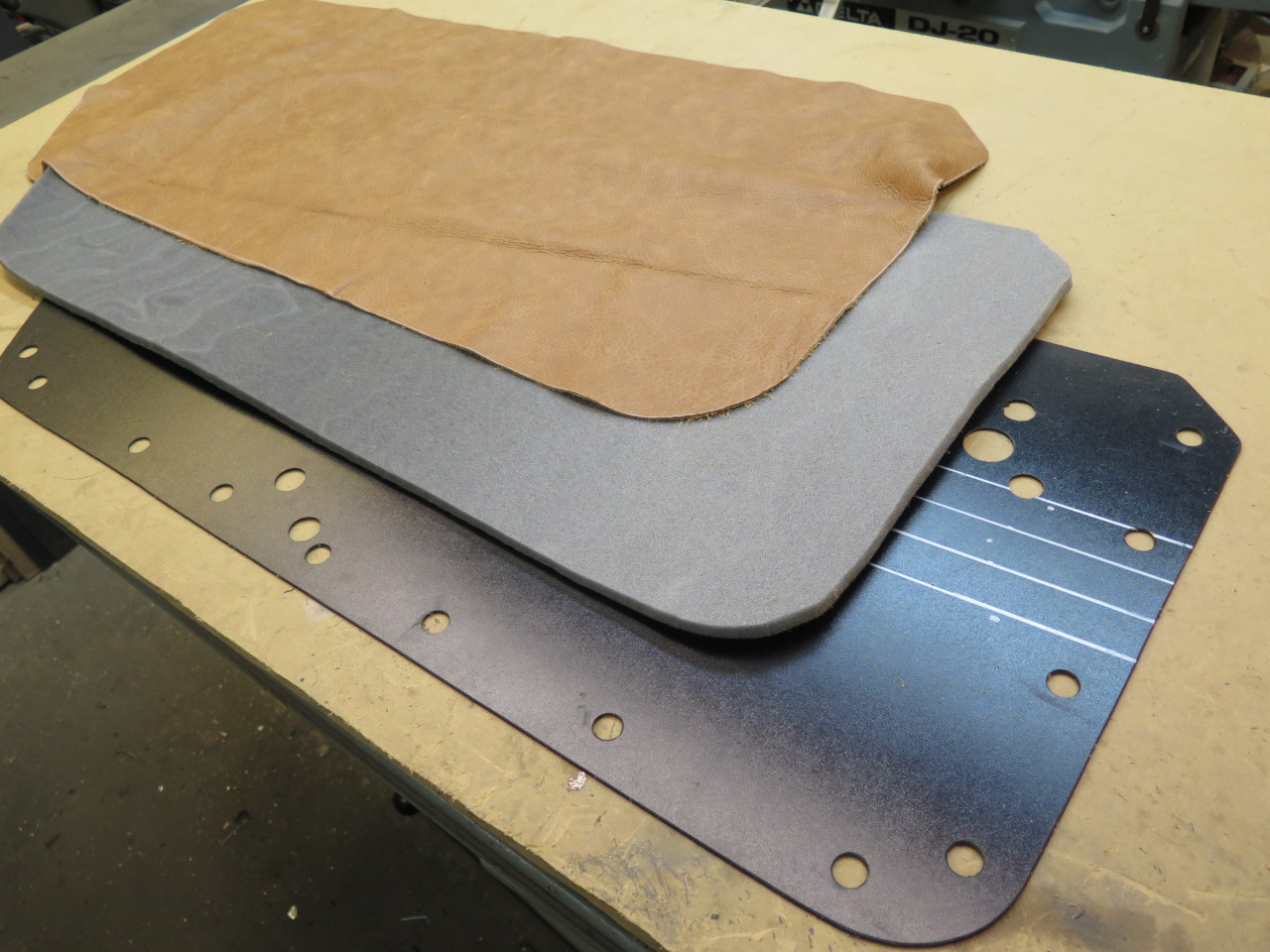

well. This is a sheet of Kydex. It is a PVC/acrylic

composite plastic that is waterproof, very tough, and has low

flammability. It was originally developed for interior partitions

in aircraft.

Kydex typically comes with a smooth and a textured side. I put the

textured side as the backside of the card, reasoning that glue will

grip better. I cut it by scoring it, like plastic laminate.

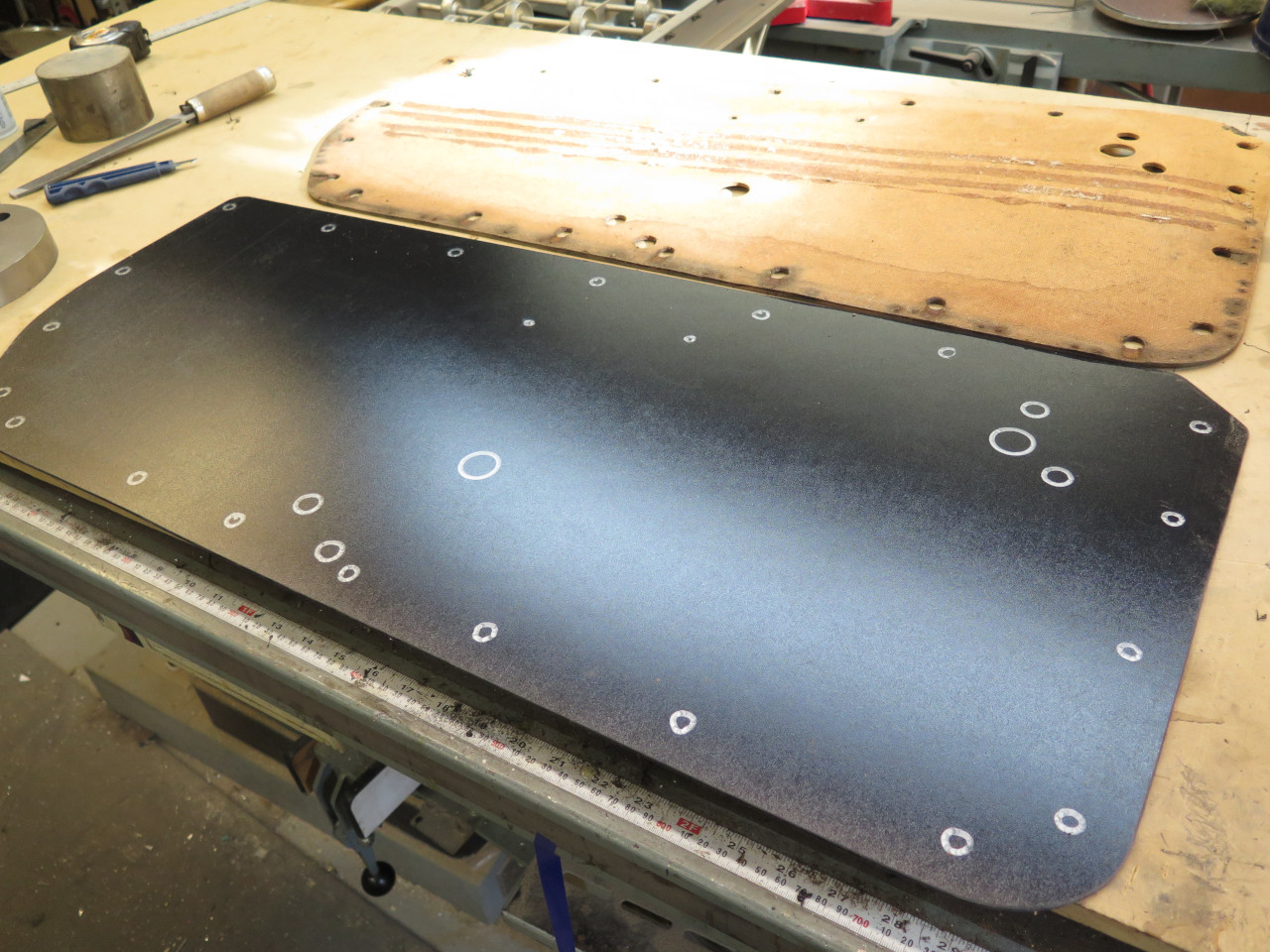

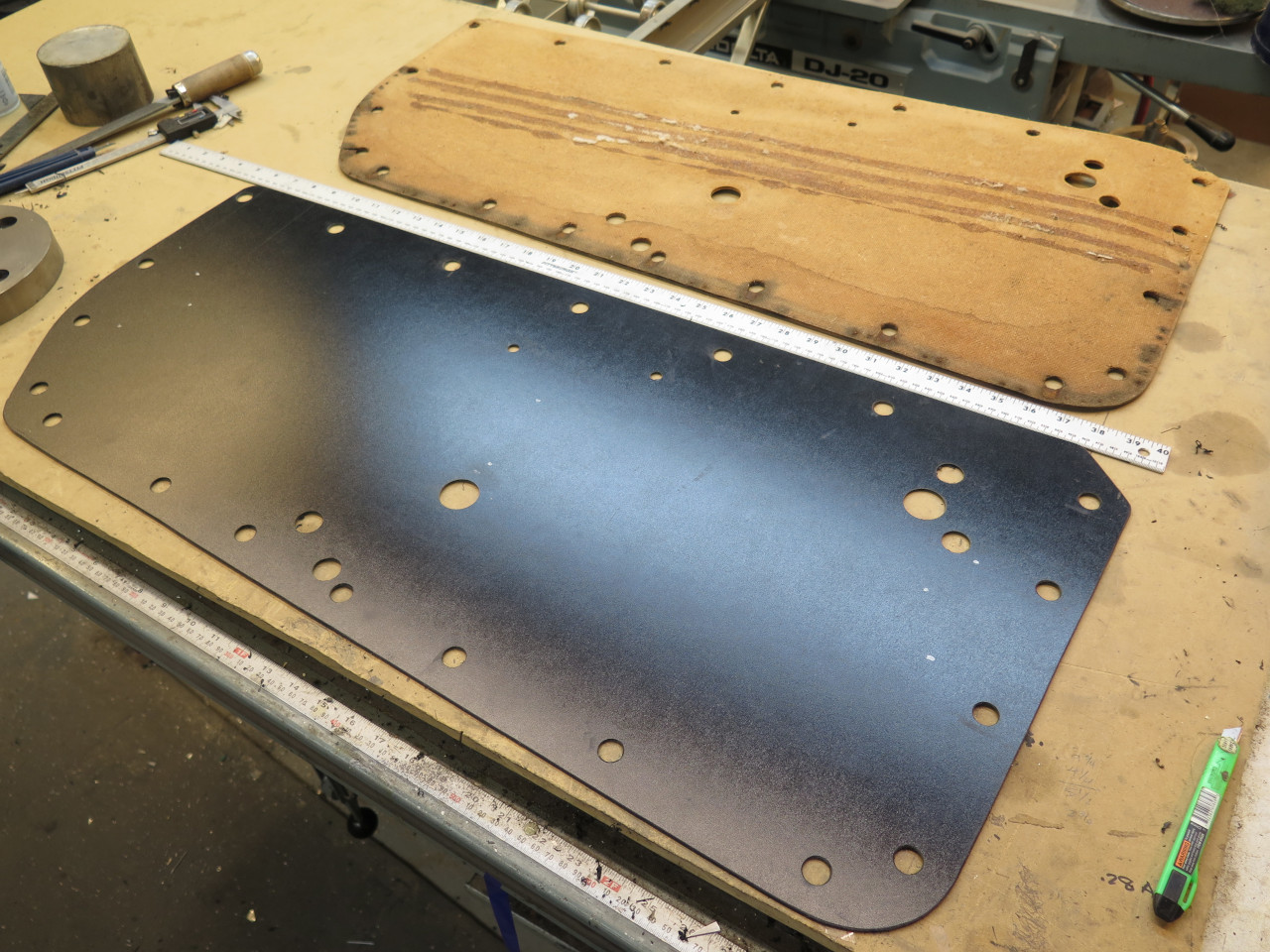

Cut to shape, then all the various holes were marked and drilled.

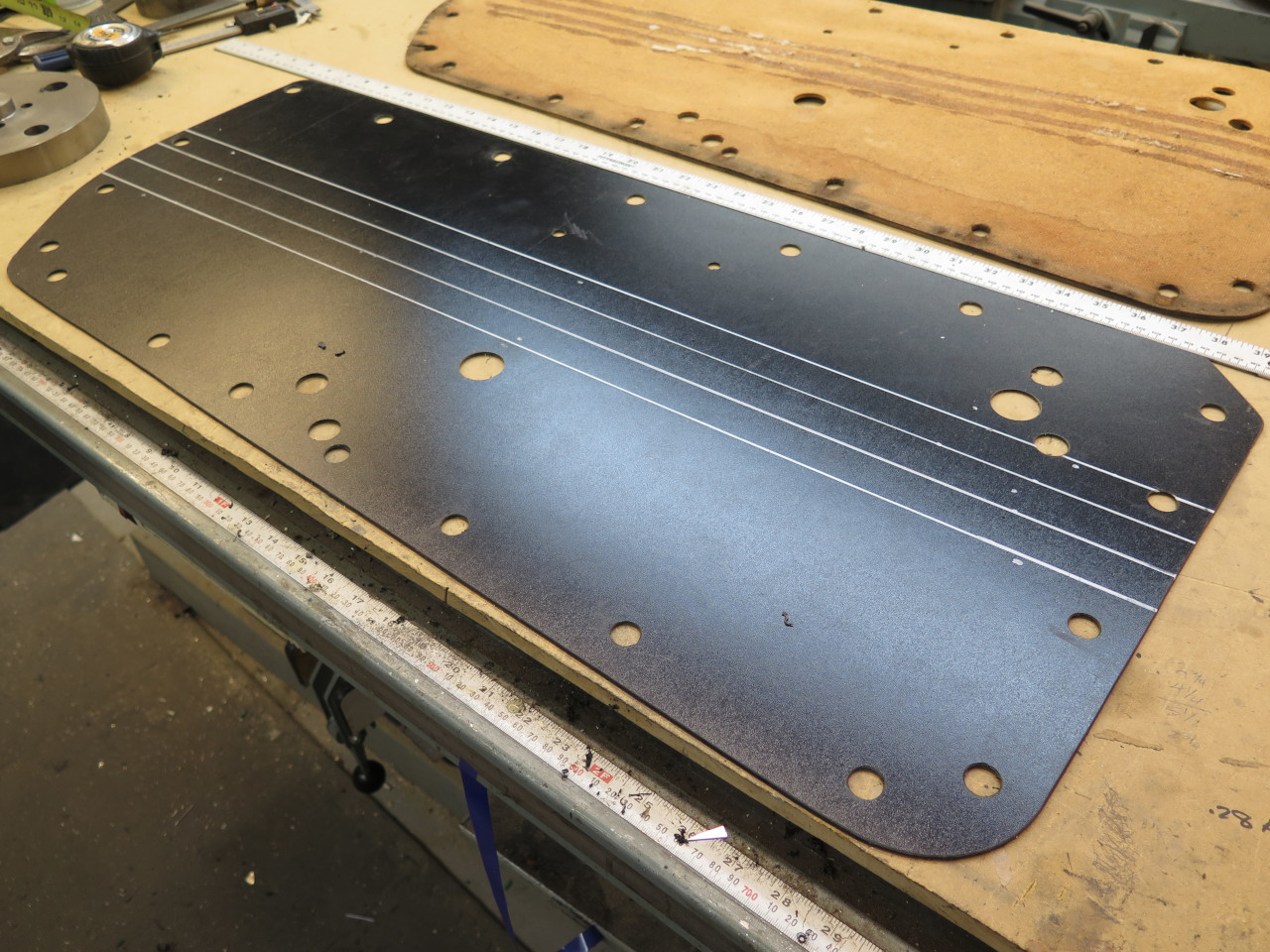

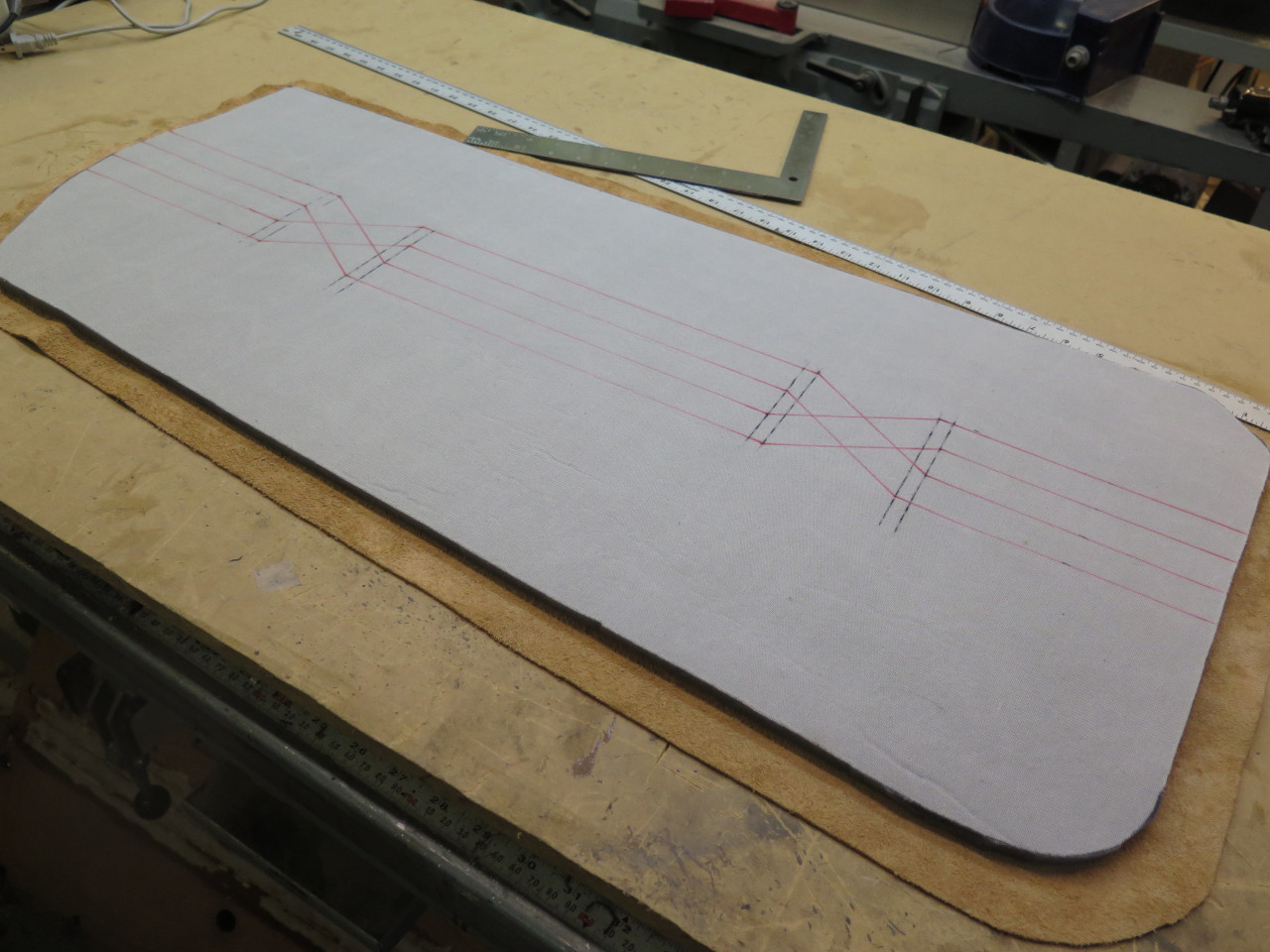

I then started laying out for some sort of stitched design on the

panel. I wanted it to reflect the original parallel lines, but

maybe with a twist.

Cut some leather and some foam to fit. That is "sew foam" or

"scrim foam". It has a fabric bonded to one side so that it will

hold stitching. I used 3/8" foam to try to lush the interior up a

notch. I used 1/2" on my TR6 door cards, and they look really

good, but the door handle and window crank drag on the vinyl, and will

eventually probably leave a mark. Not sure if 3/8" will have the

same problem.

This is the stitching pattern I came up with. It's similar to a

pattern I used on the TR6. I guess it's a little link between the

cars.

Getting ready to mount the leather/foam to the panel. The white

donuts are to bring the thickness of panel up to the same as the

original, so that the panel clips will fit properly. The Kydex is

0.080" thick, so I needed another 0.040" or so. Standard plastic

laminate (e.g. Formica) worked great.

Glued the covering to the panel, sort of stretching slightly as I went.

When there is a pair of items, especially for jobs I don't do often, I

typically do one at a time in case I need to refer to an original.

The second one always goes faster.

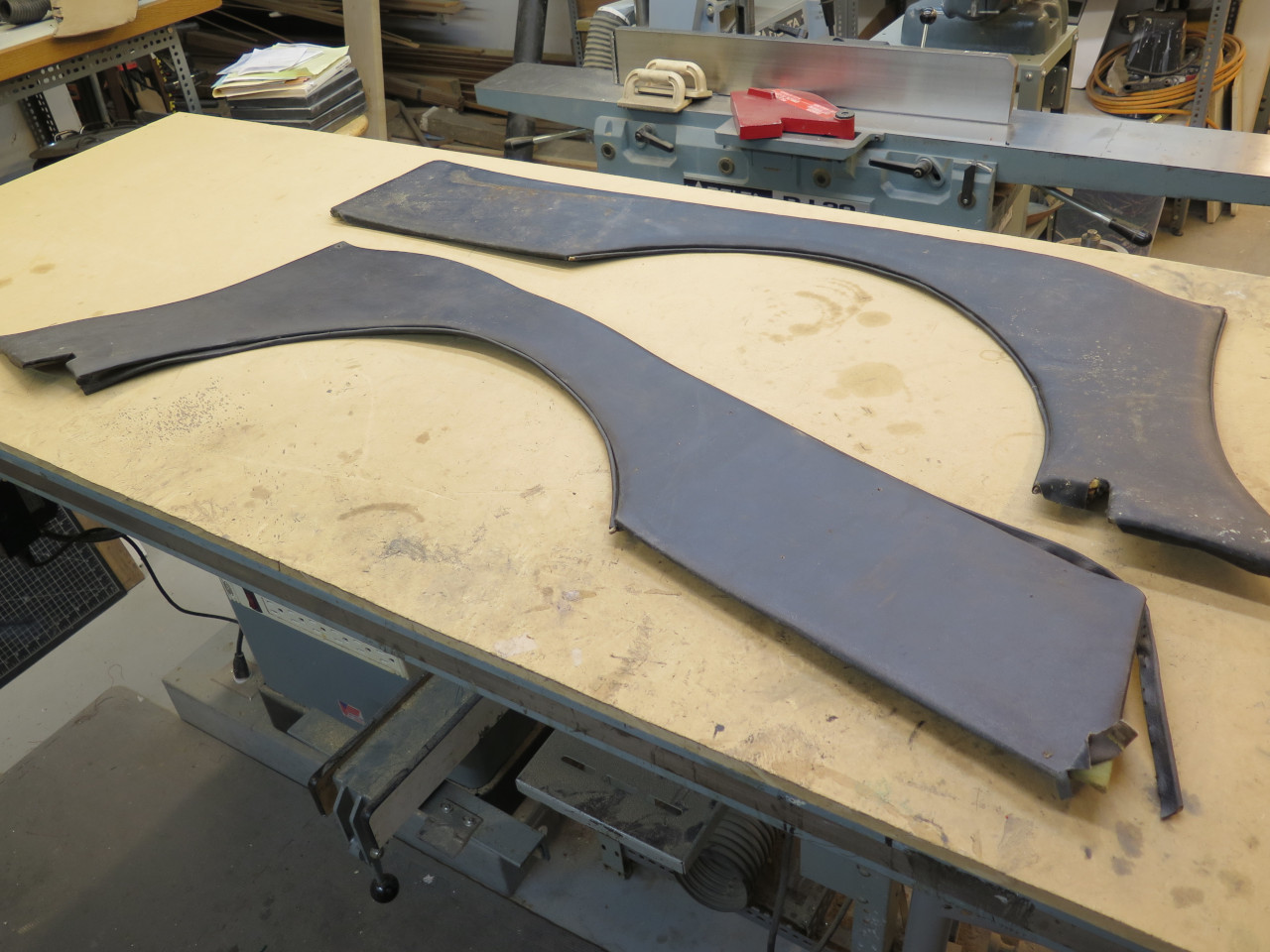

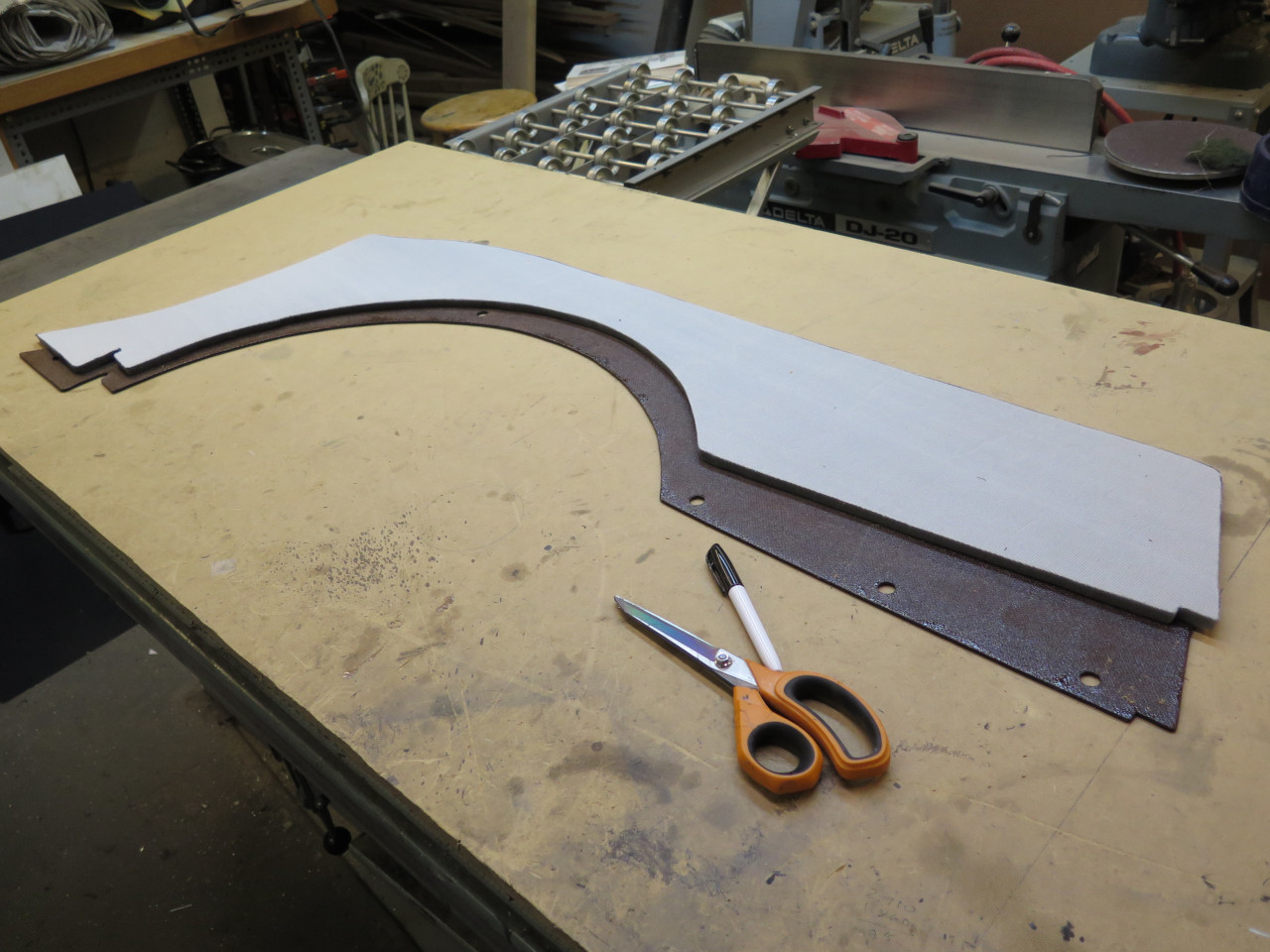

The wheel arch cards were even more nondescript--just flat hardboard

covered with thin vinyl and 1/8" foam. The hardboard was in

relatively good shape, but some of the mounting holes were damaged.

Since there was no evidence of water exposure on these cards, I didn't

feel that the extra expense of Kydex was justified, but I did opt to

make new hardboard panels.

As a hedge against airborne moisture and condensation, I did apply 5-6

coats of urethane varnish to the panels before cutting foam and vinyl to

fit.

Then, just to add a smidge of character to these plain parts, I stitched

some lines that should line up with those on the door cards.

Then put it all together.

A little over a week's work, spread over a month or so.

Not sure what else has to match.

This was a perfect pass time for the warm shop during our recent

sub-zero weather. This wasn't a cheap project, though. It

took most of a leather hide at around $200, and maybe $60 worth of

Kydex, though I have a fair amount left over.

Comments to Ed at elhollin1@yahoo.com

To my other GT6 pages