To my other GT6 pages

December 15, 2022

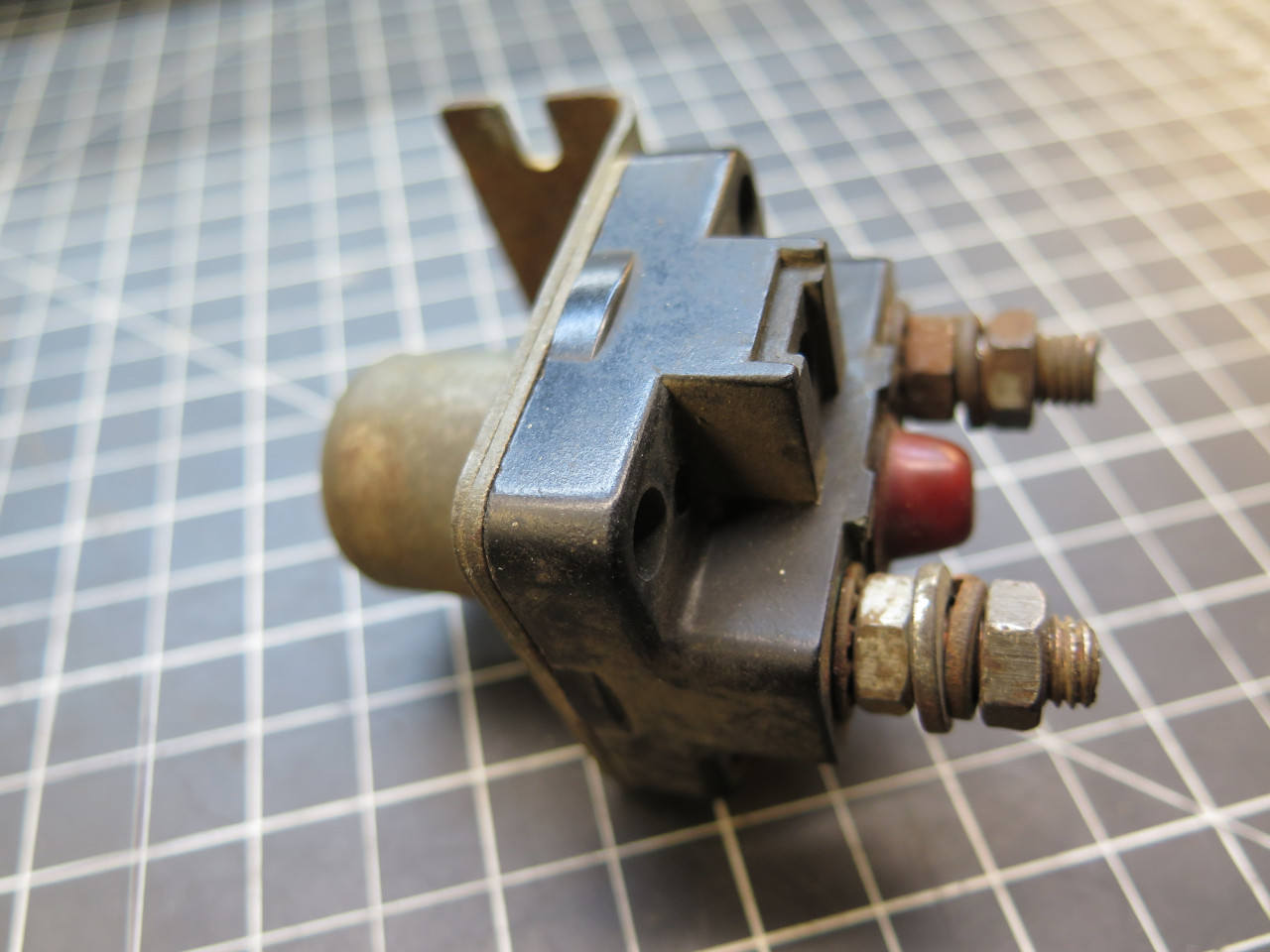

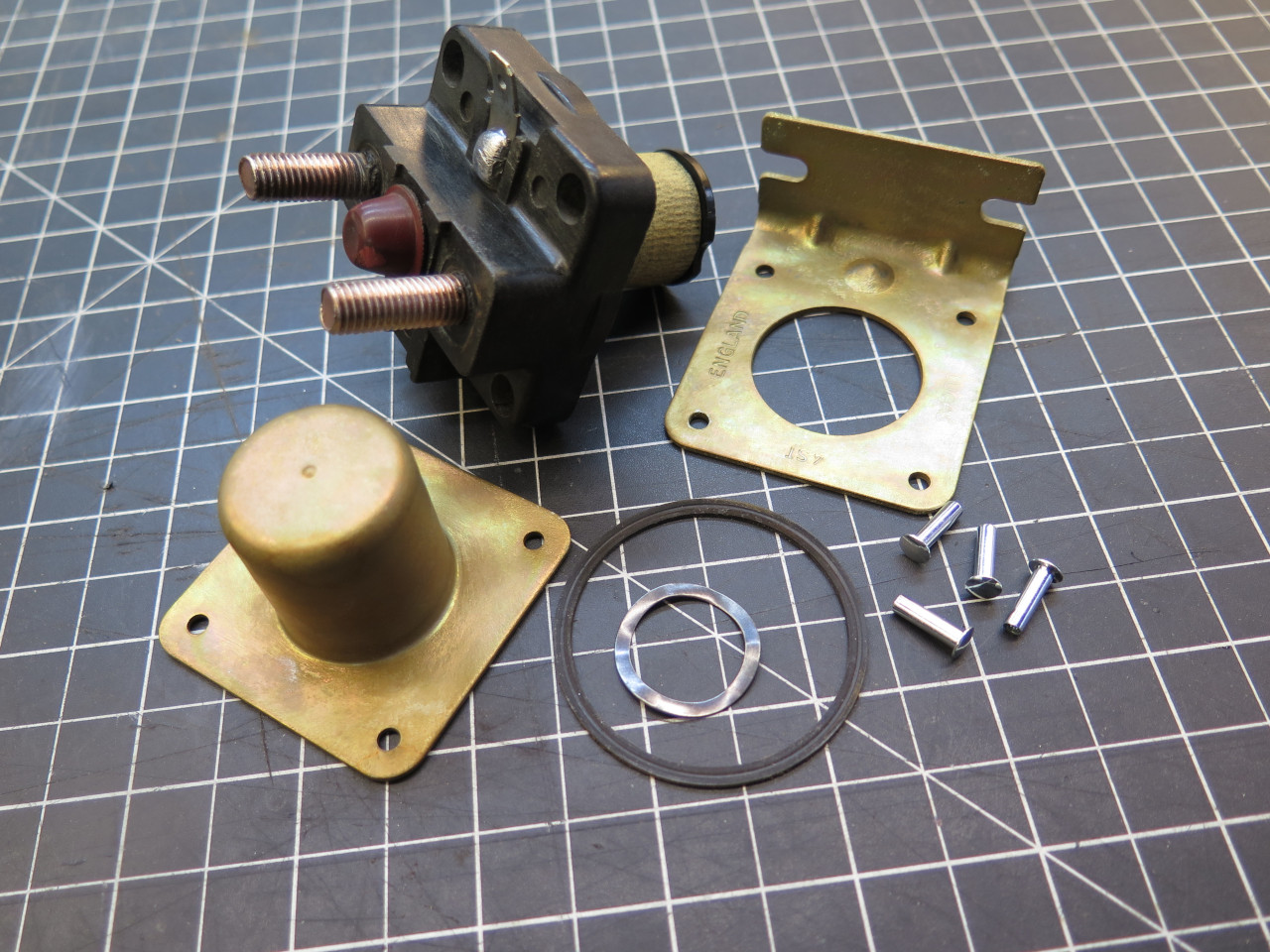

Starter Solenoid

There aren't many parts left in the boxes I filled up when disassembling

this car, but I did come up with the starter "solenoid". I put

"solenoid" in quotes because I believe it's technically a misnomer for

this part.

Though the word solenoid can refer to just an electromagnet, it is more

often reserved for an electromagnet assembly designed to actuate some

mechanical arrangement. An electromagnetic device mounted on or in

the body of a starter that physically engages the starter gear with the

ring gear (in addition to making a high current electrical connection)

would properly be called a solenoid in my opinion. But if it just

operates electrical contacts, it's a relay (or "contactor" for higher

currents), and not a solenoid.

However, since the device is almost universally called a solenoid by our

LBC suppliers, and so also by most owners, I'll bow to the popular

usage.

In my research, I found that these devices are easily available, and not

that expensive. However, in keeping with the spirit of this

project, I took a close look at my original. My solenoid was dirty

and rusty in places, but it seemed to work fine, so I didn't see much

reason to think about a replacement. My job was just to make it

look better cosmetically.

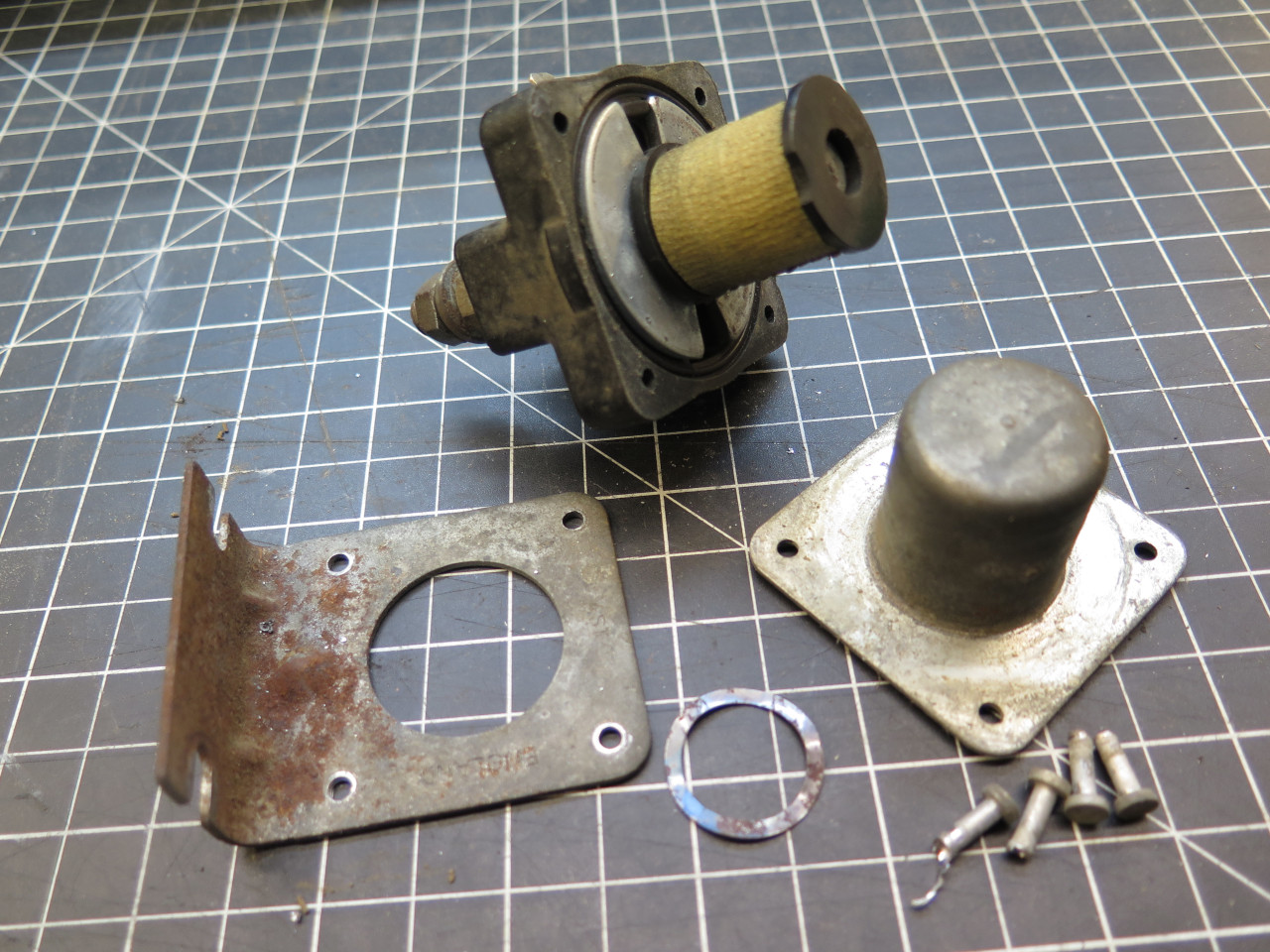

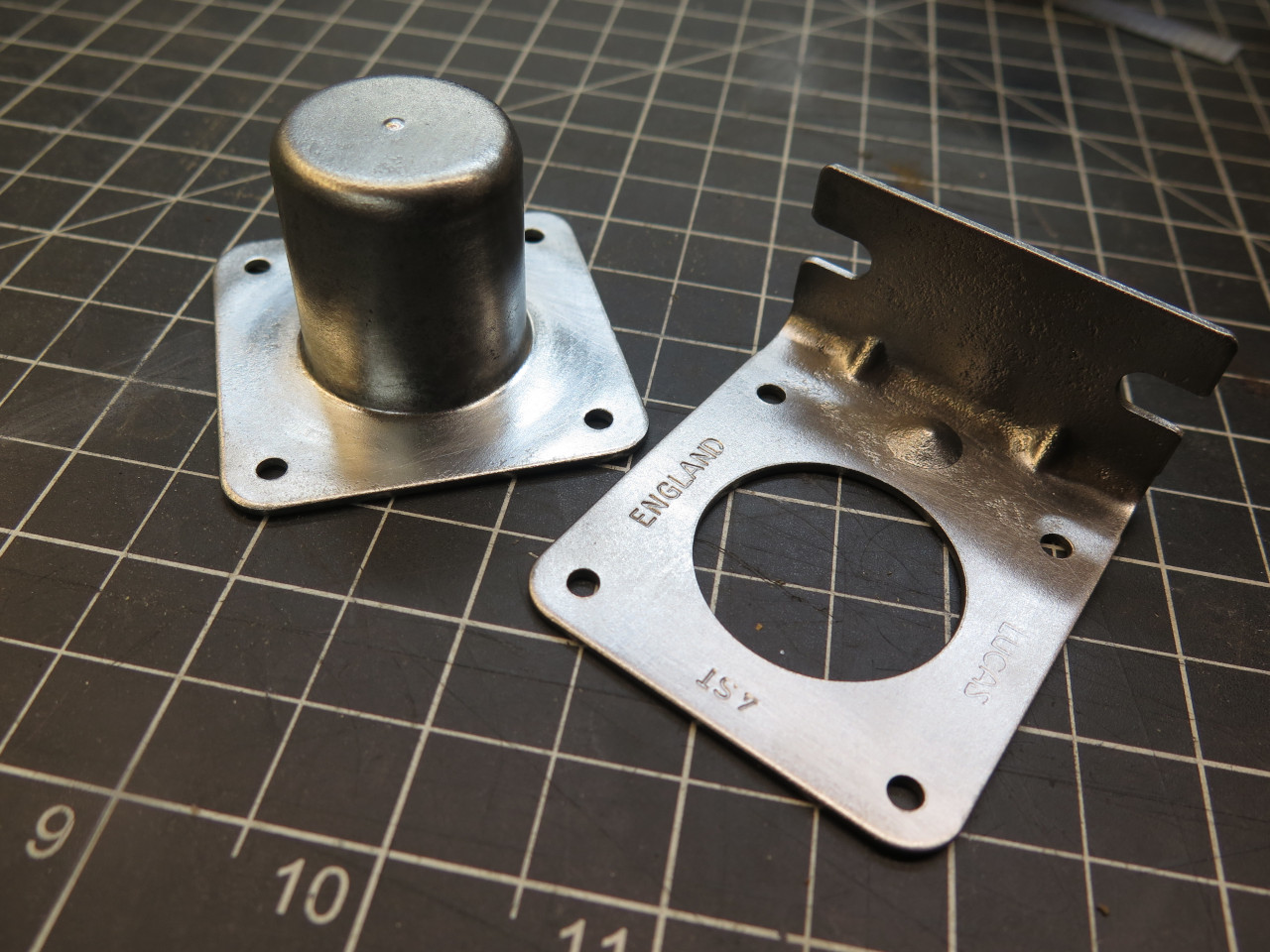

All of the rust was confined to the mounting bracket and the coil

housing. Those were both liberated by drilling out four rivets.

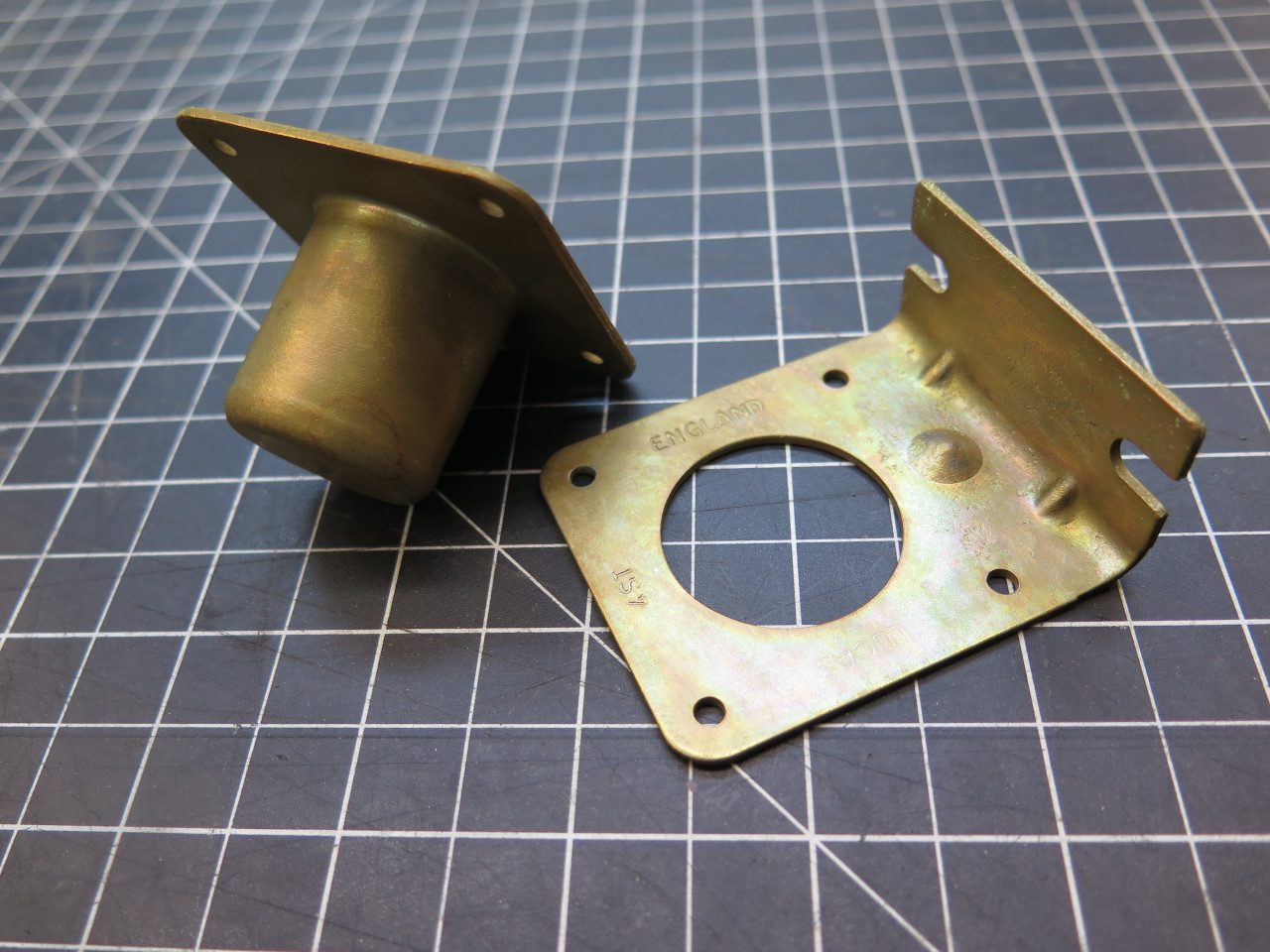

The parts were originally zinc plated, but an acid bath removed the rust

along with the remaining zinc. New zinc and chromate made them

look a lot better. The shallow pitting left by the rust doesn't

really bother me as long as the new zinc covers it completely.

Really nothing else to do before putting her back together.

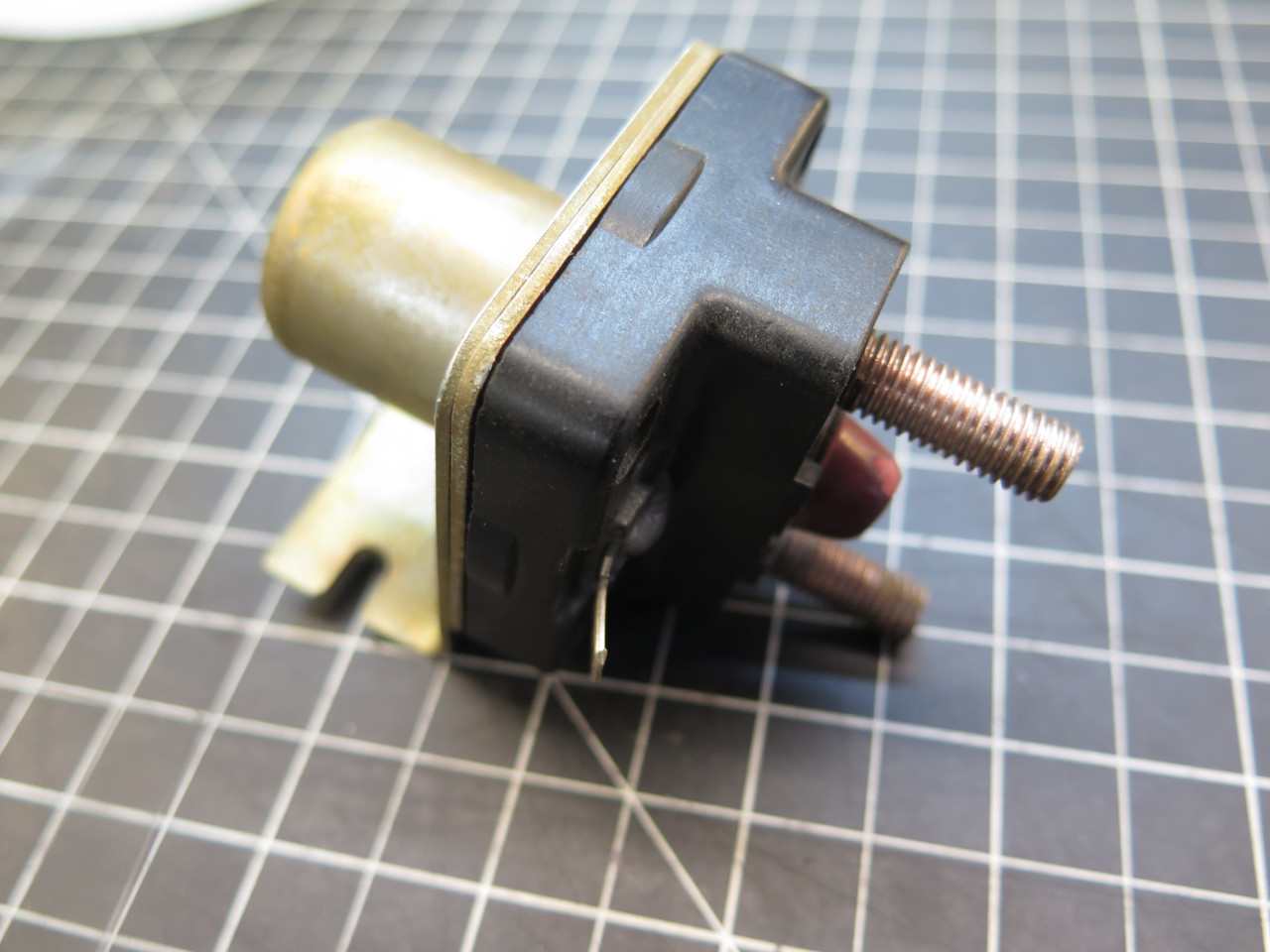

I took a look at the nuts and washers that were on the copper

studs. Oddly, the star and lock washers appeared to be copper or

brass, but the nuts looked like steel. Checking with a magnet, I

found they were all steel, and the washers were just copper

plated. This was mildly disappointing, since I really prefer

fasteners on electrical contacts, especially those carrying large

currents, to have good conductivity, not to even mention the dissimilar

metals issue.

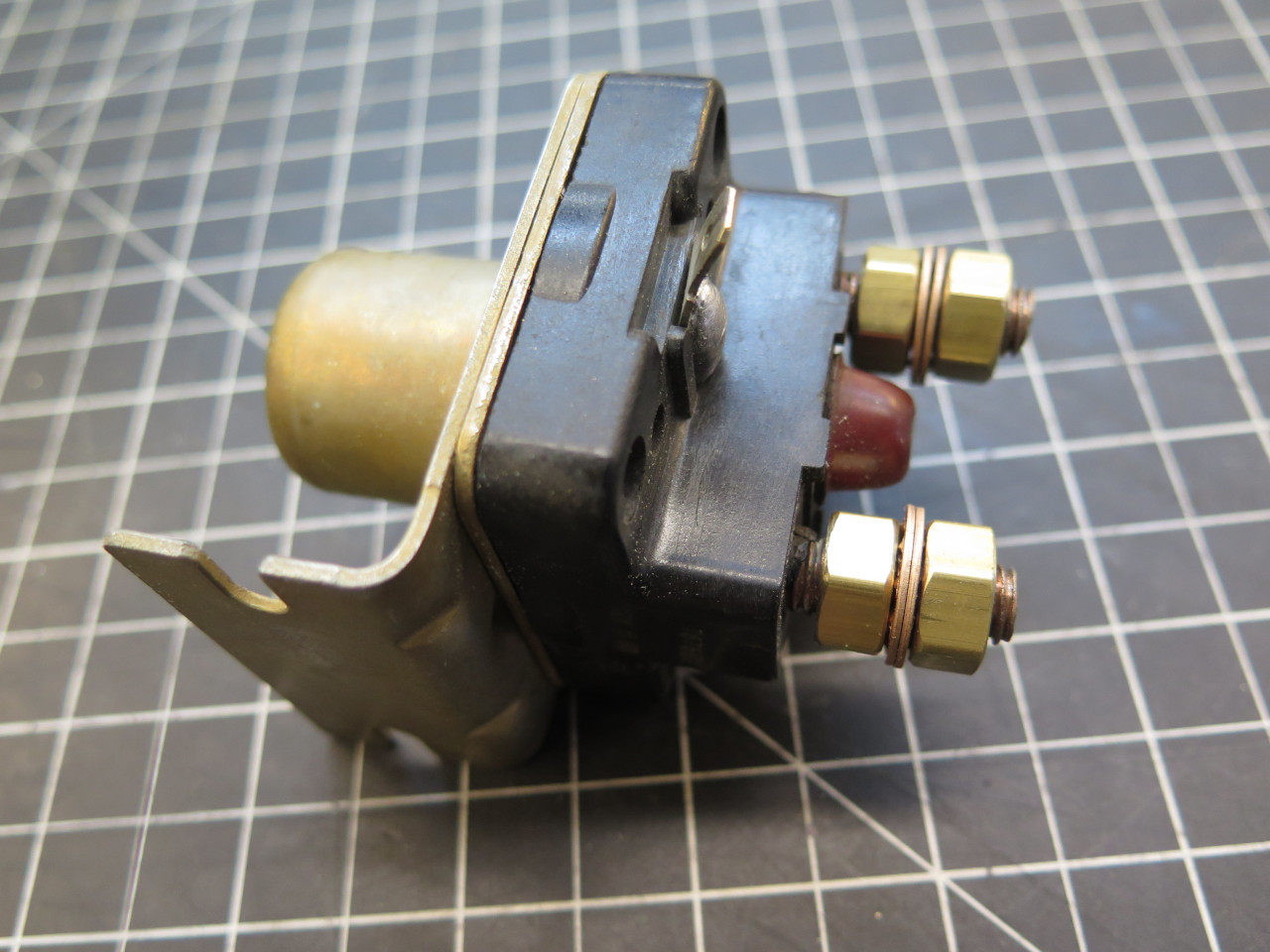

So, I thought, I think I'll just go get me some 5/16-24 brass nuts and washers to match. So that's what I did.

Then, tragedy struck. The nuts didn't seem to want to go on to

those studs. They started, but bound up right away.

Well, it turns out that the designer of his part saw fit to use not

5/16-24 studs, but instead 5/16-22 studs. 5/16-22 is actually a

British standard, BSF.

So now my problem was to find some 5/16-22 brass nuts. I could get

them from the UK, but shipping and delay made that option

unattractive. A couple of things I COULD easily get in the US

though, were a 5/16-22 tap, and some 1/2" brass hex rod.

Ready for show time...

I like these little low-risk projects. Even the drama with the

nuts wasn't that stressful. The brass rod and the tap came to less

than the cost of a new solenoid (which may not even include brass

nuts).

Comments to Ed at elhollin1@yahoo.com

To my other GT6 pages