To my other GT6 pages

December 4, 2022

Side Mirror

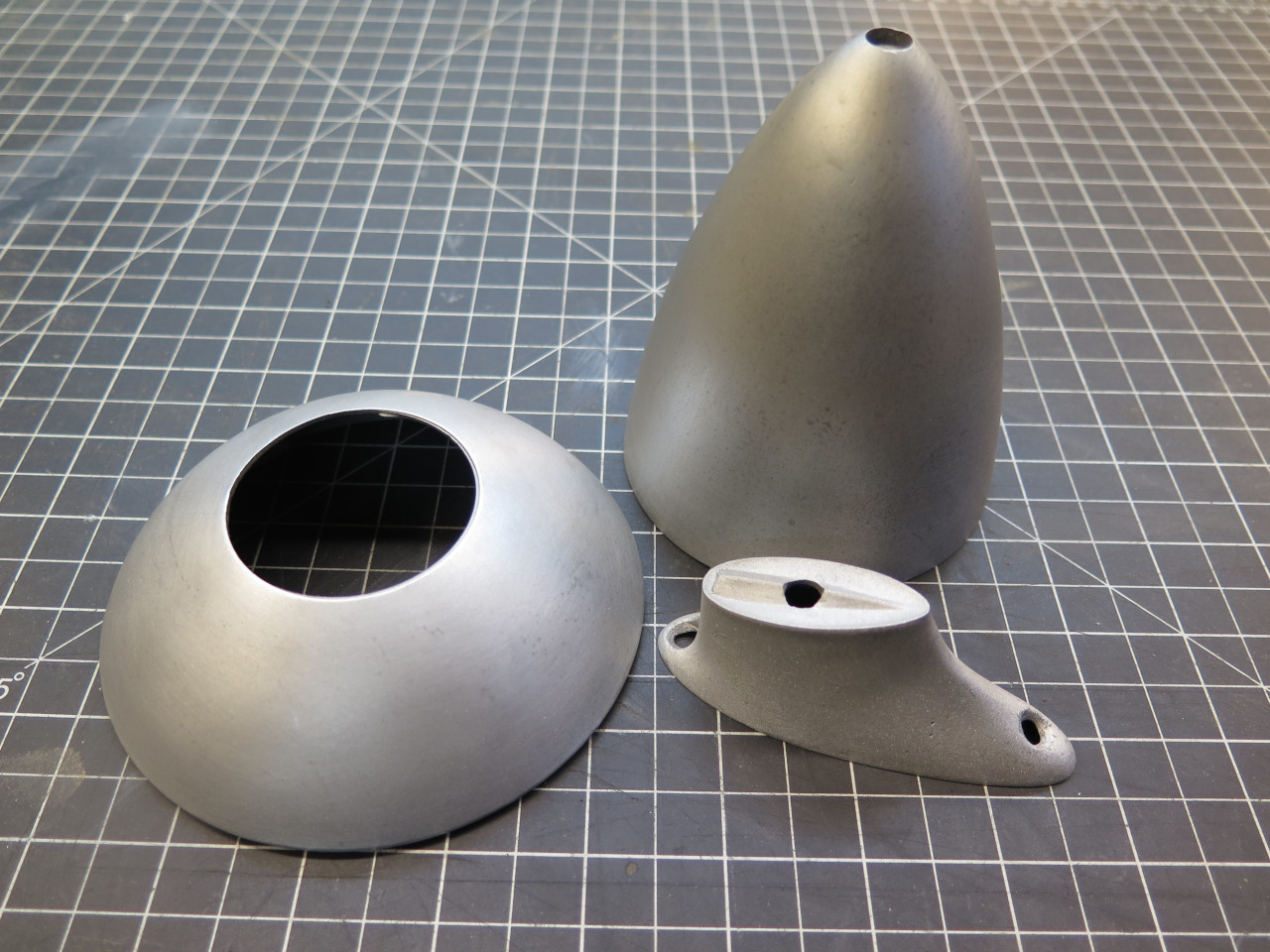

The side mirror that was on this car when I bought it was a black bullet

type. It appears to be the same mirror that was on my 74 TR6, so I

assume it was common on Triumphs of the era. I've read that side

mirrors may have been dealer installed items, but I don't know if the

factory supplied them, or if the dealer sourced them locally. At

any rate, I believe this mirror to be original to the car.

It was cosmetically in pretty bad shape. The actual mirror

glass was missing.

It appeared to be salvageable though, so I disassembled it.

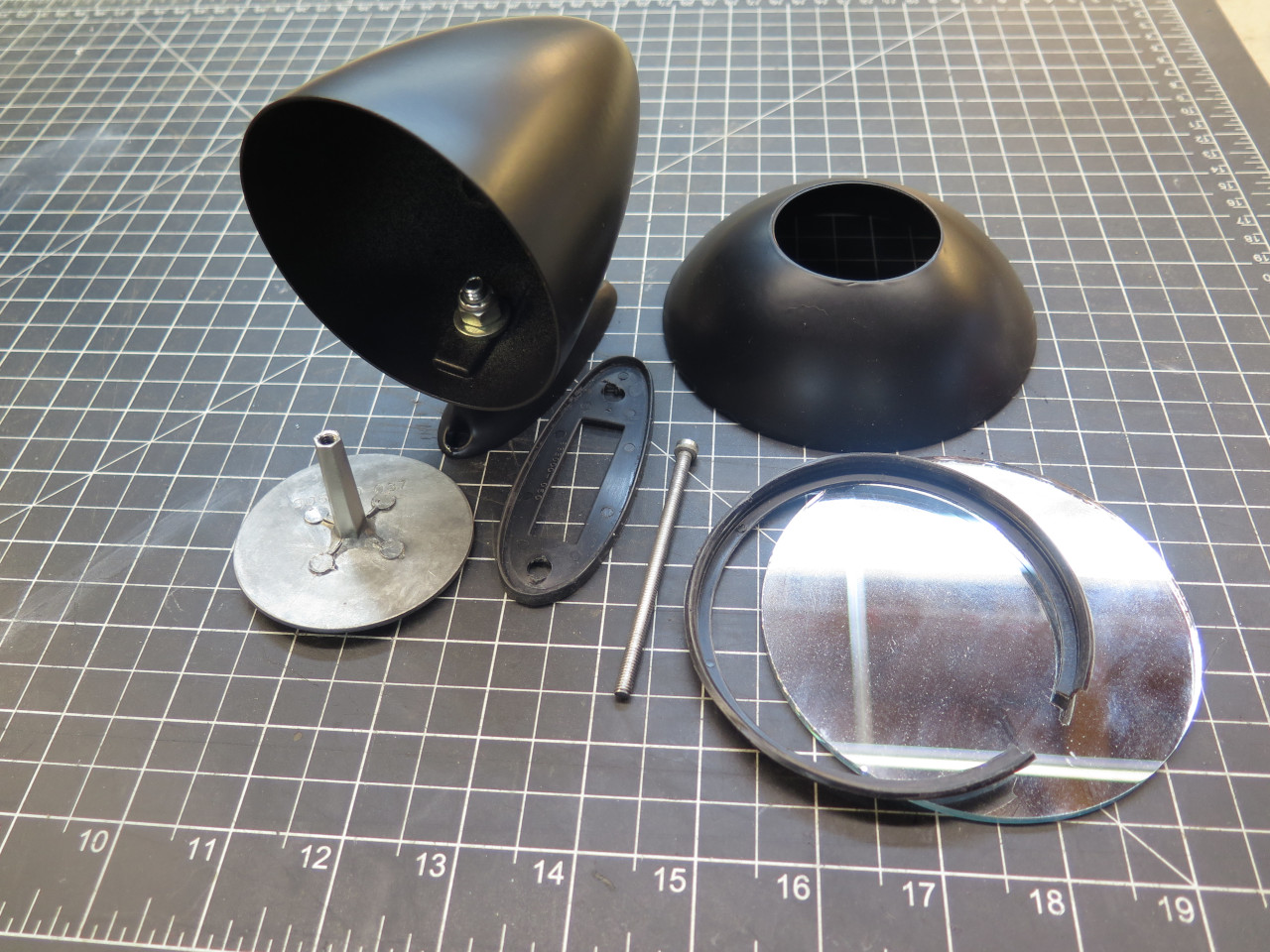

The die-cast mirror holder is tensioned against the main body with that

disc and long bolt. Everything looked pretty OK, except for the

shaped plastic ring that goes between the body and the moveable mirror

holder. It's job is to provide a resilient seat for the mirror

holder so that it can be tightened down enough to keep it in position,

but still allow adjustment without damaging the paint. The problem

was that it had apparently shrunk, and no longer fit properly on the

rim of the body casting.

I tried several things to try to re-size the seat. What worked the best was to heat it, and stretch it over a form.

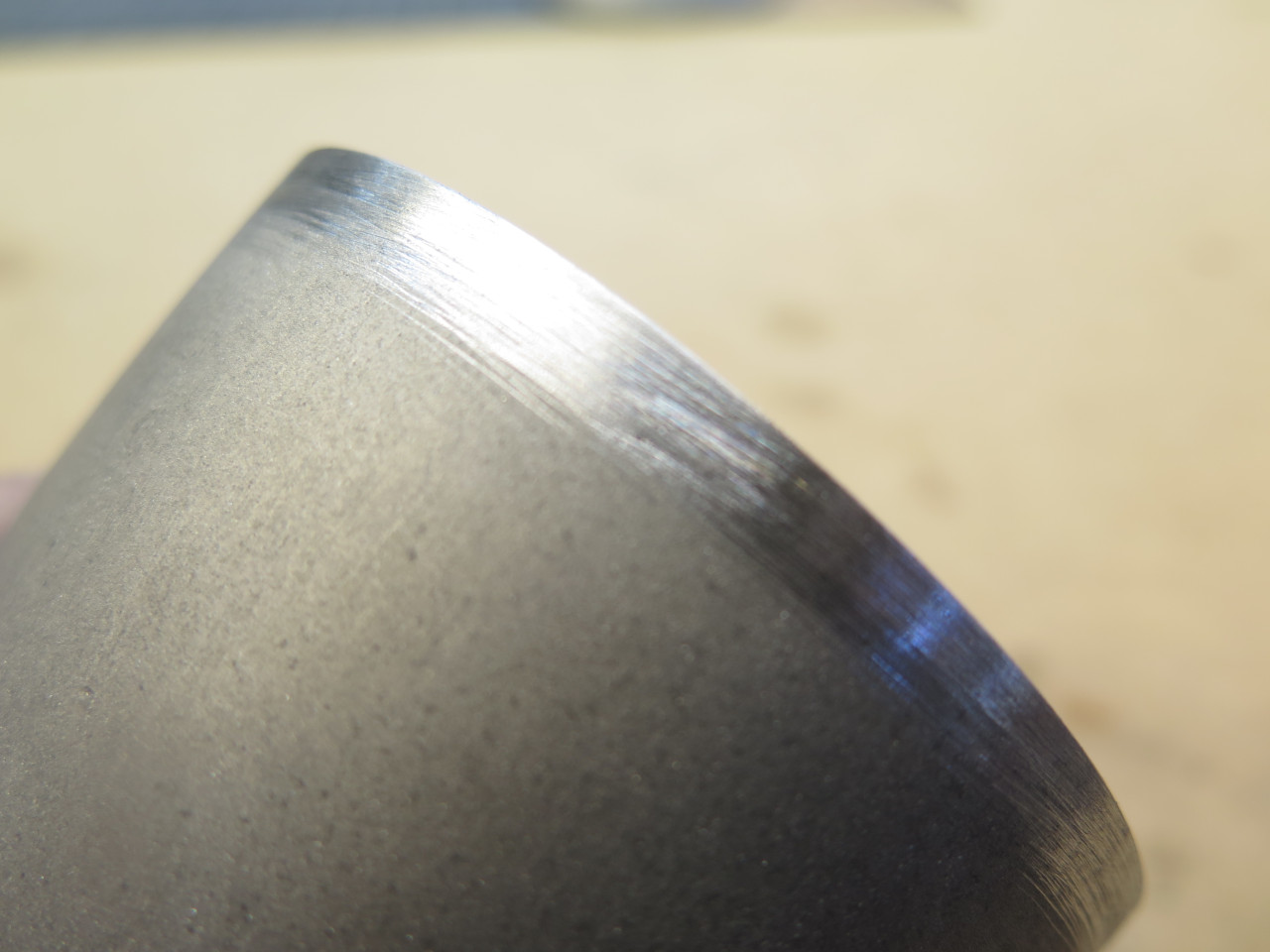

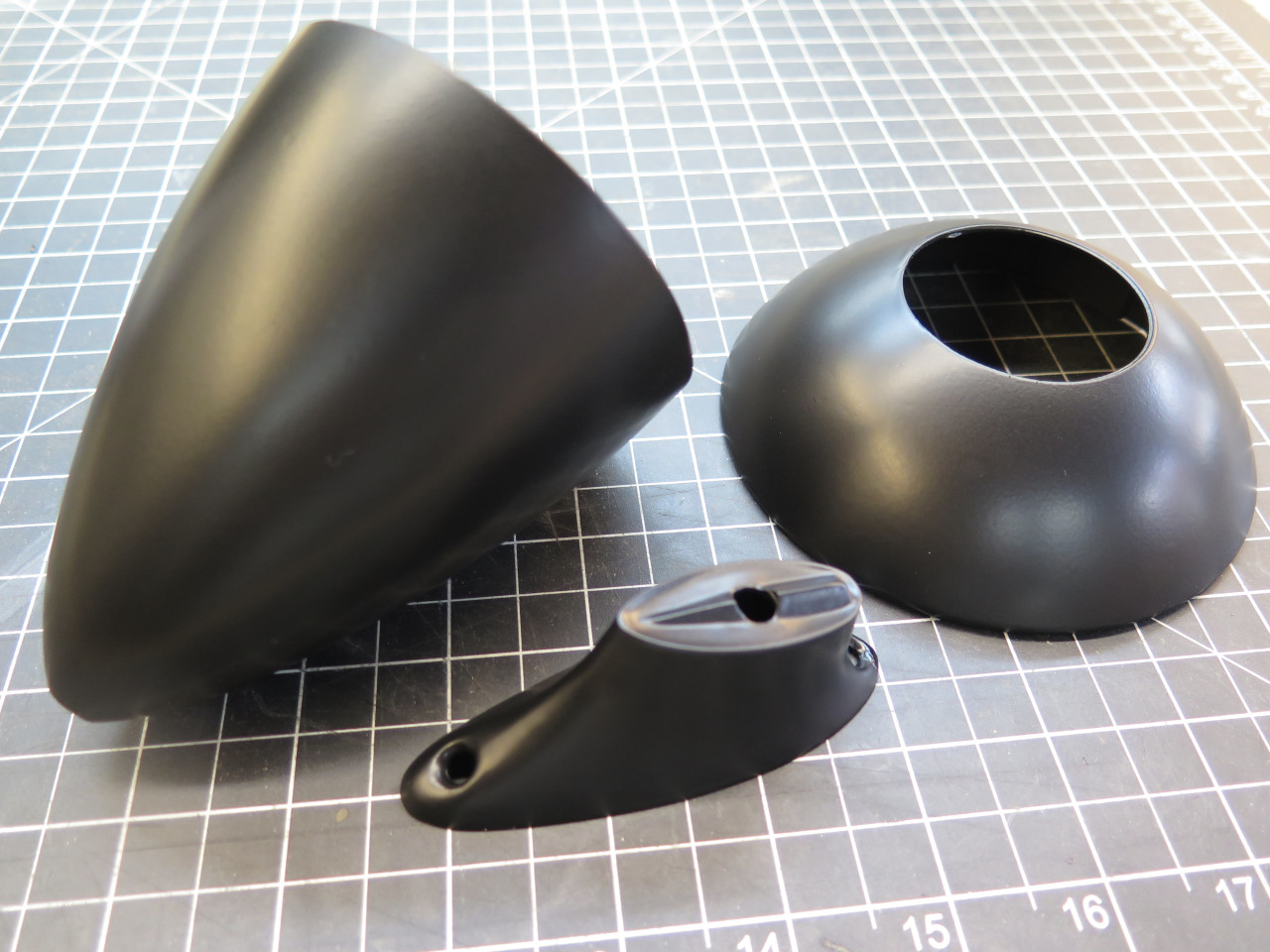

While the seal was cooling, I turned to the three die cast parts. A light blast made them look a lot more respectable.

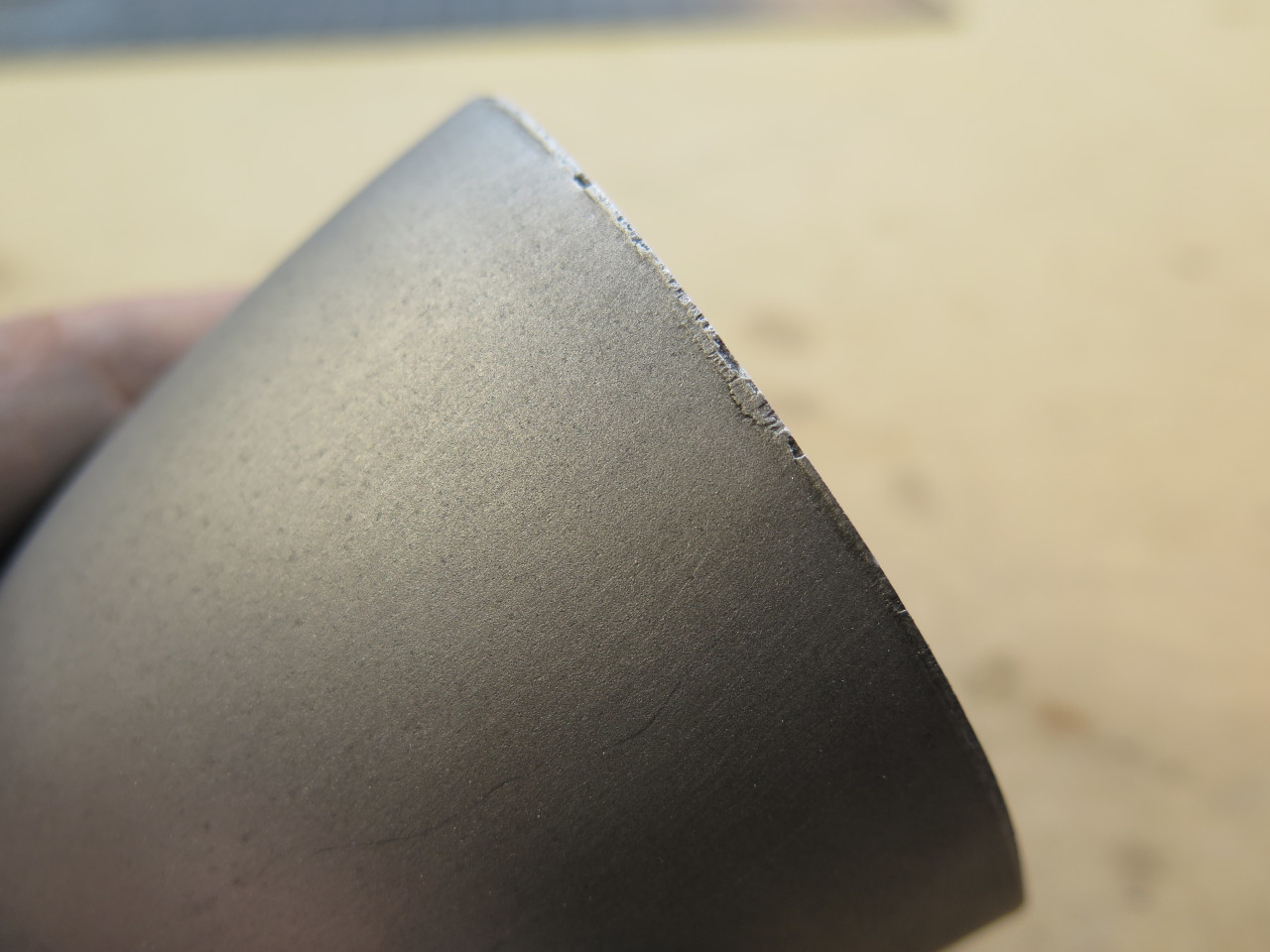

As is typical with relatively cheap die cast parts, there were casting defects on the edges.

These don't really hamper function much, but what better time to clean them up, just on principle?

A re-blast to even up the surfaces, and a nice coat of two part epoxy primer, followed by a tasteful satin topcoat.

Ready for reassembly. Notice the broken plastic seat. My

stretching protocol was working brilliantly, and I got the seat fitting

almost perfectly. In a classic bridge-too-far call, I decided to

try to get that last millimeter or two of stretch. After the

swearing was done, I reasoned that it wasn't really a crisis, and placed

the gap at the bottom, where I now call it a drain for any water that

might make its way inside the body.

There was one other bit of heartache before I was done. I got the

the 4-inch round mirror glass at a hobby store, and it was very slightly

oversized to the point that it wouldn't seat in the mirror

holder. I made a half hearted attempt to grind the edges, but all

this did was chip the backing so the edge looked even more ragged.

I found plan B online as a 4-inch automotive replacement mirror.

It even has a nice bevel edge. I discovered the hard way on a

previous project that the backing on most mirrors doesn't like most

adhesives, so there are specialized mirror adhesives.

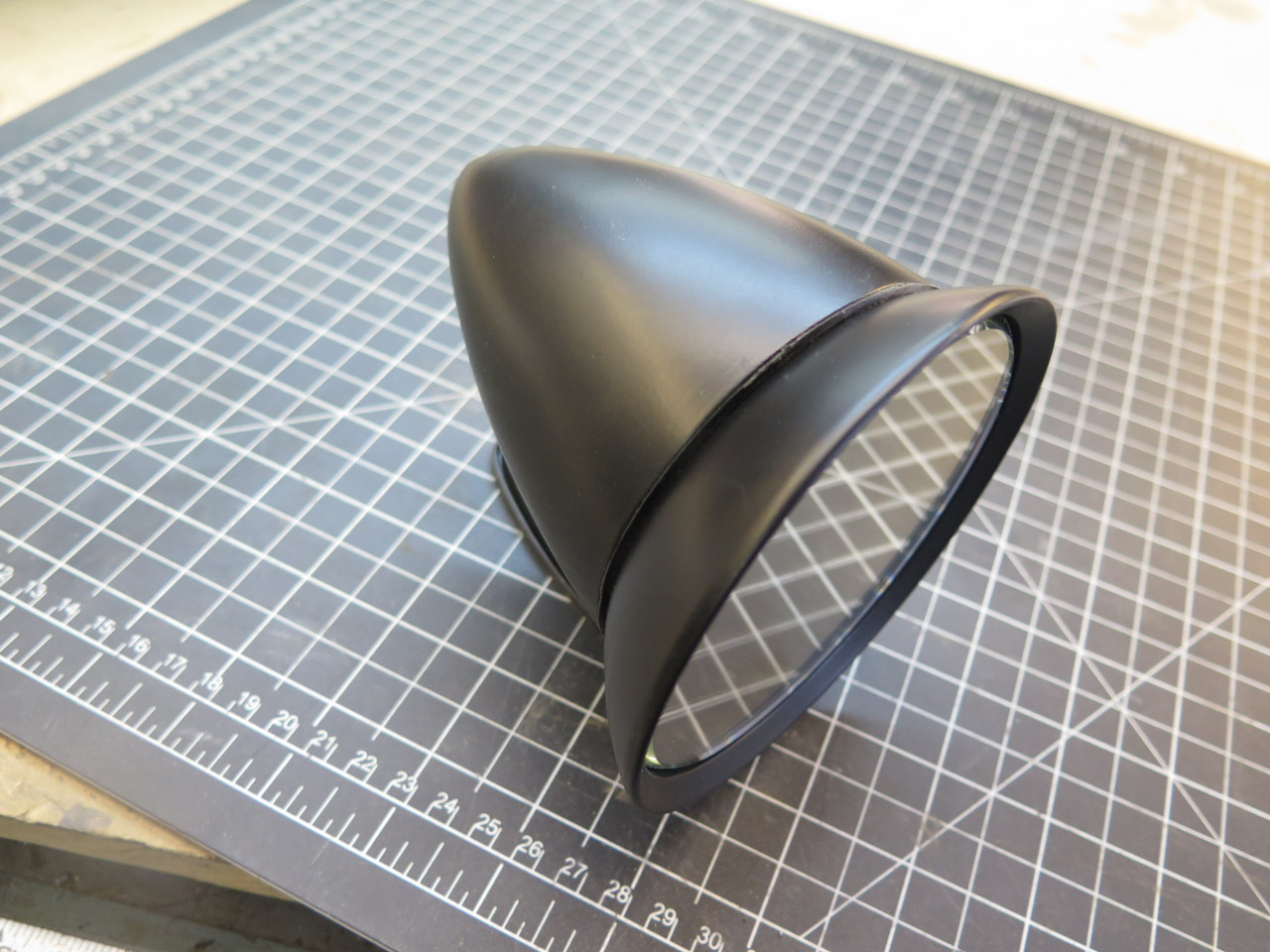

Ready to go...

These simple, quick little projects make nice interludes between the

more harrowing ones. This one took a few hours, and the cost was

just a few bucks for the mirror.

Update, April 10, 2024

Fast forward almost a year and a half, and it's already time to install this puppy.

First, where, exactly, does it go?

Looking at some old pics of the car, I saw that the mirror was mounted

on the driver's door pretty far forward. A pic of the stripped

door shows mounting holes that indicate it was just a few inches from

the door's front edge.

Looking at some period brochures, most show a bullet mirror like mine,

but usually chromed, and mounted further back on the door. Sitting

in the car and playing with mounting positions, I could see why this

was the case. In the more forward position, the driver sees the

mirror through the wing window, and it is often partially obscured by

all the window framing. It looked like most cars in the brochures

had the mirror mounted so the mirror glass was roughly in line with the

trailing edge of the wing window frame. An epiphany followed

shortly. That larger hole in the door must have been for the

original mirror, which apparently mounted with a single bolt.

So now, I had to choose an exact mounting location. Fore/aft

position was suggested by the brochure photos, but the up/down position

was dictated partly by clearance with the wing window.

This puts the mirror base right on the most curved part of the

door. This bugged me a little, since I saw that the mirror foot is

flat on the bottom, not curved. It seemed to me that this

couldn't provide a stable base, and would permit rocking of the mirror

up and down. I checked the little plastic pad for the

foot. It wasn't curved either. It was clear by then that

this was probably a period replacement mirror, and that possibly the

original mirror had a foot that matched the curve of the door. (Or

maybe that's expecting too much.)

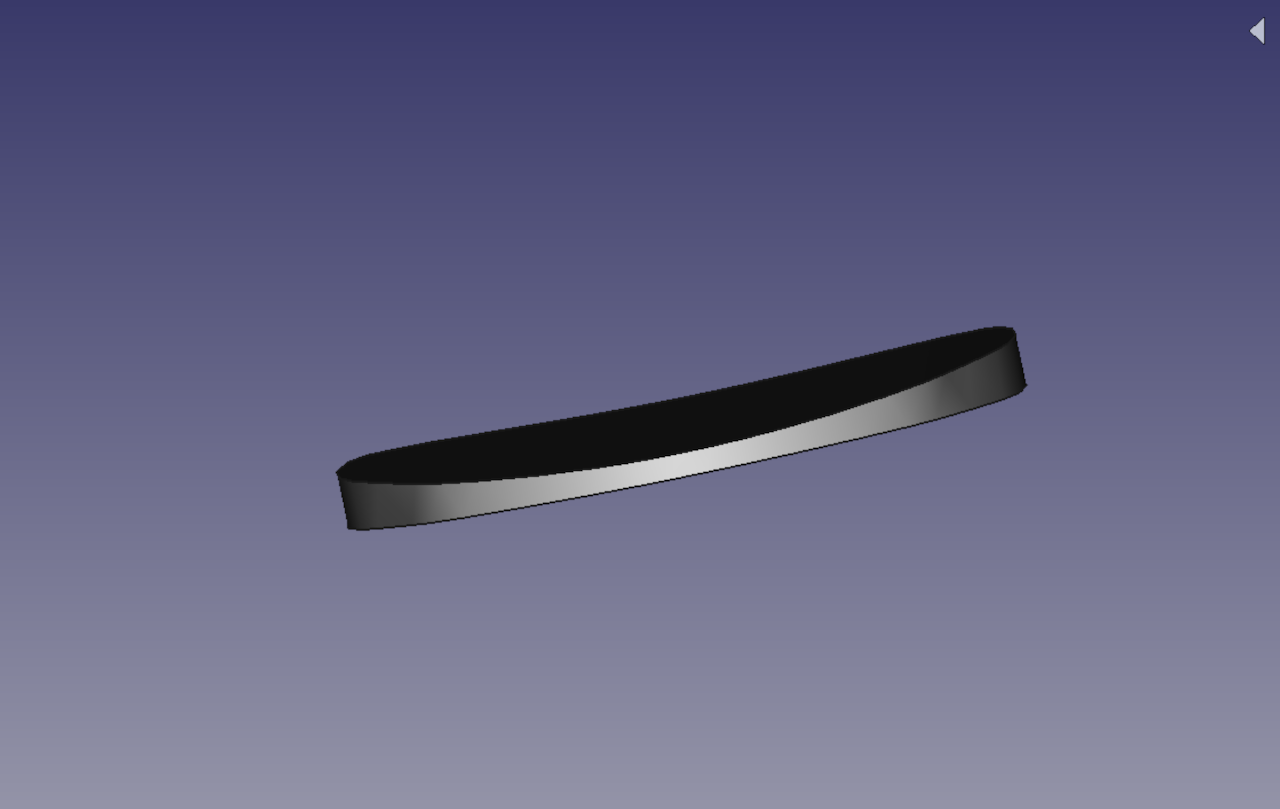

I measured the radius of the curve. it's only about four inches.

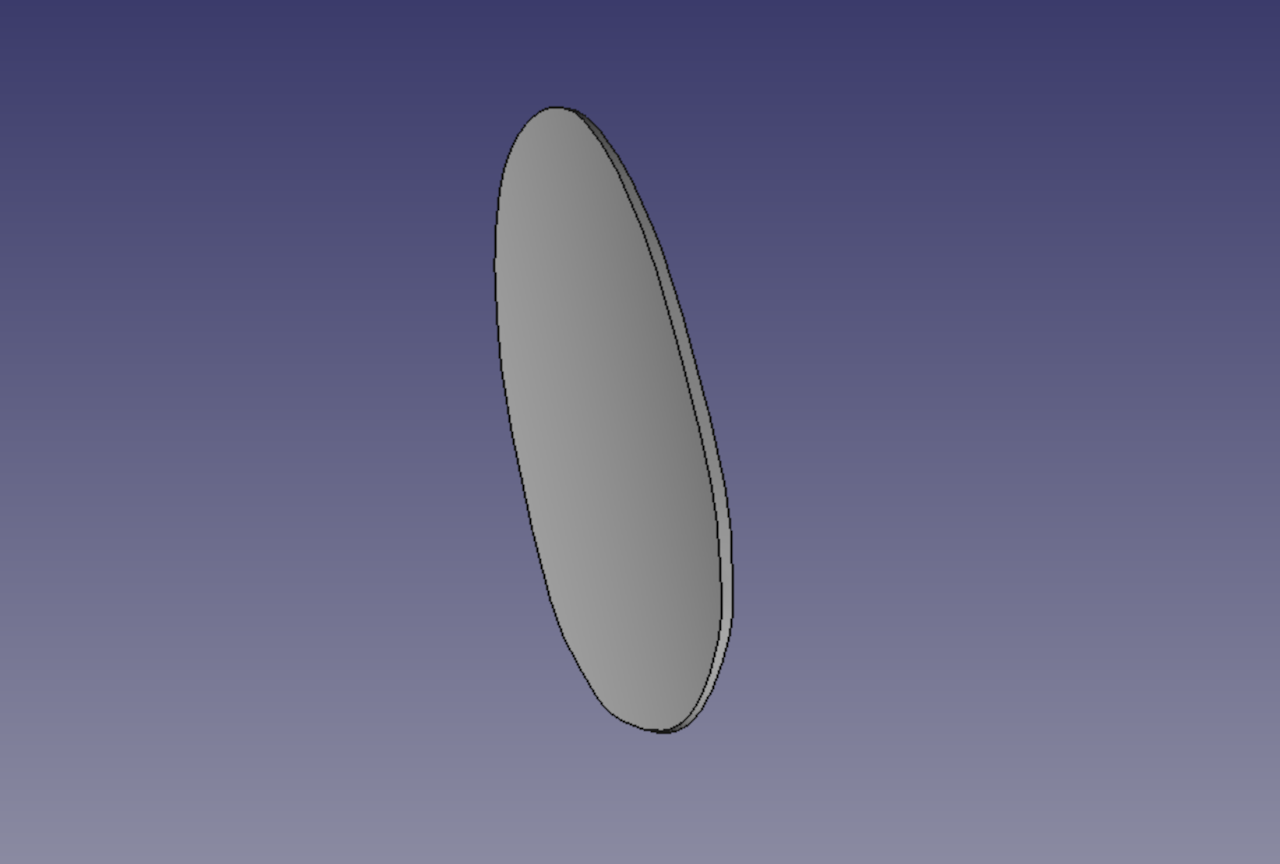

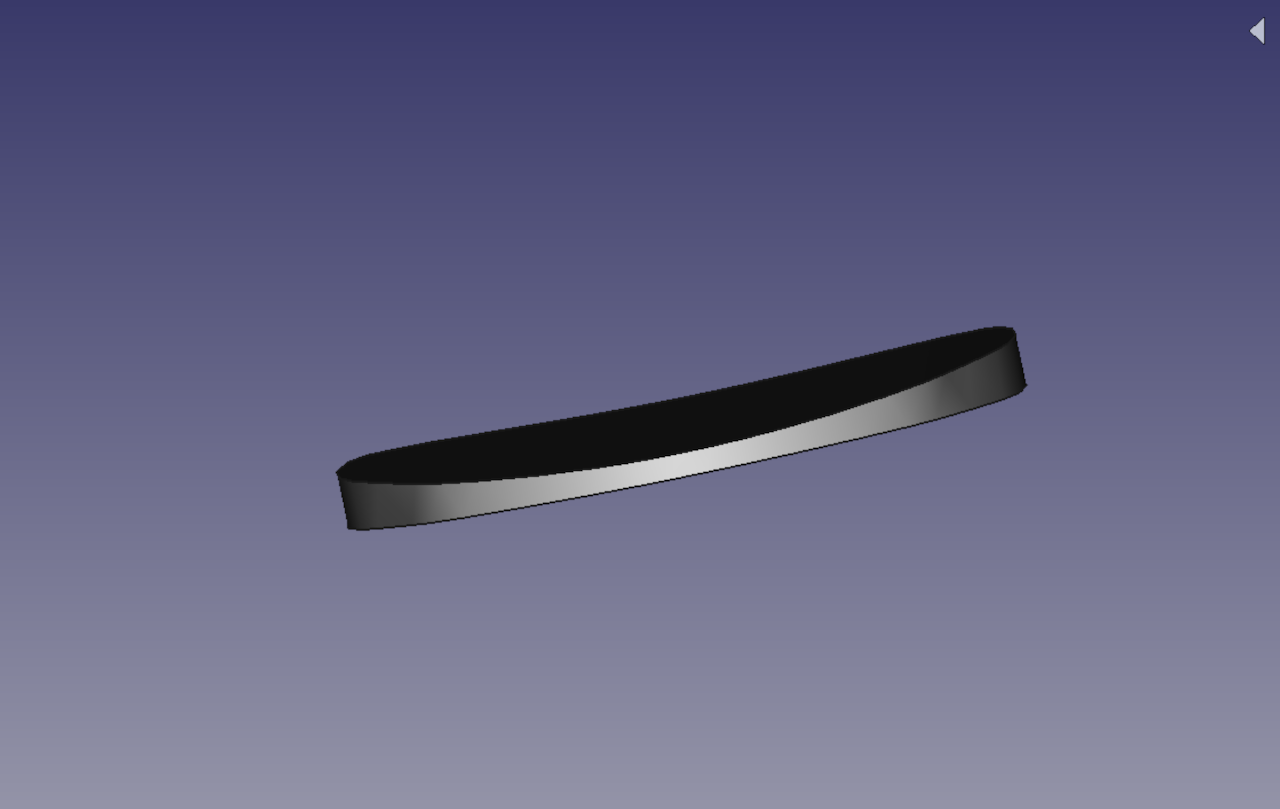

Well, 3D printer to the rescue again. A little shim with the same

shape as the mirror foot pad, flat on one side, and dished to a four

inch radius on the other.

One more irritation before moving on. The mirror mounted with two

sheet metal screws directly into the door skin. This is bad

enough, but they each had to be at a pronounced angle. This just

seems like lazy design to me, but I suppose the price point had a lot to

do with it.

Well, I couldn't really abide this, and resolved to try to use proper

fasteners instead. By reshaping the holes in the foot a little, I

was able to get a pair of machine screws to fit vertically. This

immediately suggested Rivnuts for the door (partly because I didn't

really want to take the door card off again).

So, after measuring half a dozen times, I drilled a couple of holes in my bright and shiny door, and installed the Rivnuts.

Then fit my new shim. I printed the shim without holes and drilled

them afterward. The thickness of the shim is just about the same

as that of the flange of the Rivnut. [The eagle-eyed will notice

that in this pic and some others, the shim or foot is installed

back-to-front backwards. Luckily, I could just flip them after I

realized the goof.

The machine screws pull the foot down pretty solidly with the shim.

The downside of changing the fasteners is that when attaching the entire

mirror unit, there is no good screwdriver access to the screws.

A cocked Phillips driver can screw them in, but to tighten them, I had

to use a little right angle driver, a quarter turn at a time. It's

worth it to me.

Small step, but it makes a visible difference.

Comments to Ed at elhollin1@yahoo.com

To my other GT6 pages