Inexpensive Blast Cabinet Mods

To

help with the rebuilding of my old Triumph Motorcycle, I bought this

small benchtop blast cabinets from Tractor Supply. It was

around $100, and is similar to one offered by Harbor Freight, but has the chamber door on the top rather than on the side.

[Click pictures to get a bigger view. Except this one]

While

the cabinet worked passably well, I soon discovered a number of annoyances.

First, the cabinet leaked media. I was using glass beads,

and after using it for half an hour, there was media everywhere on he

bench and the floor. I know now that glass beads on the floor

behave a lot like millions of tiny ball bearings when someone steps on

them.

Second,

the fluorescent lignt in the cabinet is worthless--it was sometimes

hard to tell whether it was on or off. It was also towards the

back of the cabinet, putting the front of larger pieces in shadow.

Third,

the bottom of the cabinet has two sloping sides to form a trough for

the media to collect in. The pickup tube lays in the bottom of the

trough. After blasting for a while, the media tends to collect at

the end of the trough away form the pickup end of the tube, causing the

tube to suck air. When this happens, you can't just scoop the

media over to the other side because of the mesh screen. I

resorted to tilting the entire cabinet to move the media to the other

side.

Fourth, after using the unit for a while blasting flaky rust, the blast nozzle started getting clogged with big flakes of rust.

Lastly,

the interior of the cabinet got very dusty after a few minutes.

Some sort of vacuum would help clear the dust for better

visibility.

I finally reserved a weekend to improve the performance of the cabinet.

The

first thing I did was to take the entire cabinet apart and reassemble

it with gaskets and/or RTV to attempt to make it media-tight.

The

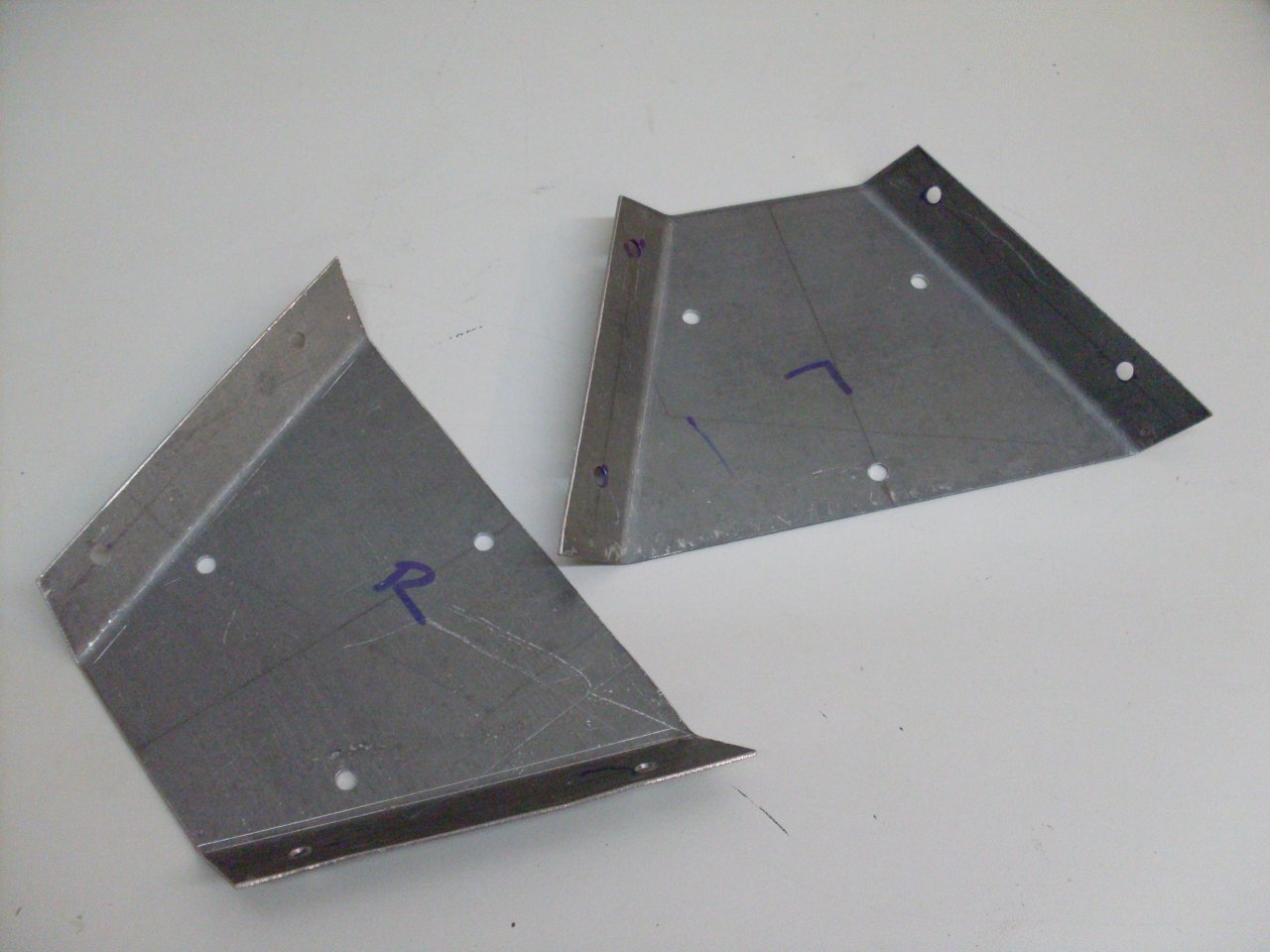

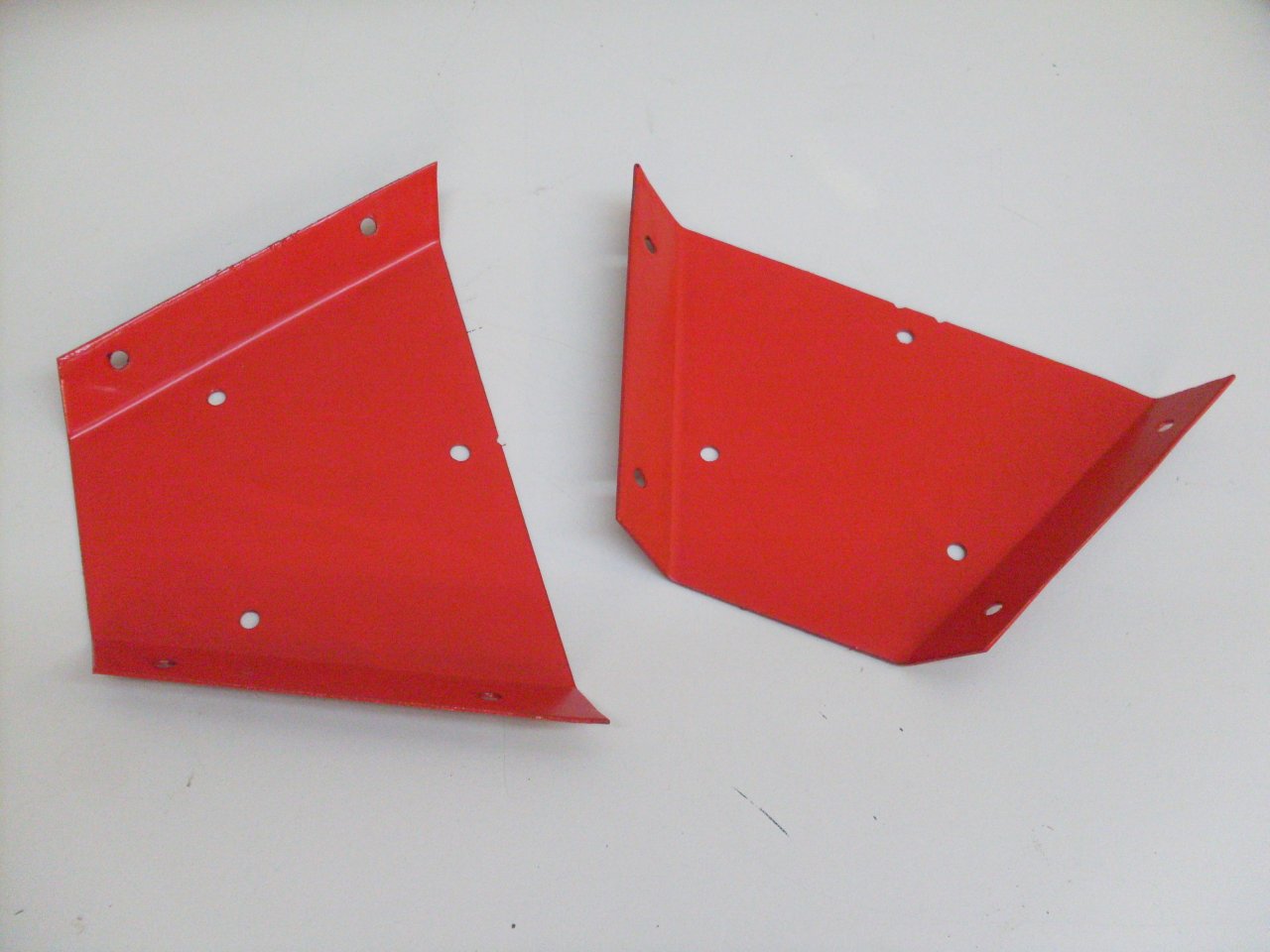

next thing was to improve the lighting. I had a set of five

20-watt halogen under cabinet lights that I never used on a remodeling

project, and decided to use three of them. I placed one light in

the center of the front wall, just under the lid latch. The other

two lights went on custom corner brackets that aimed the light toward

the center of the blasting space.

These

lights are 120 VAC, so no transformer was needed, but for safety, I put

the wiring in flexible conduit. The conduit connected to an

internal box that hooked to the original exterior light switch.

Next

up was to improve the way the media collects at the bottom of the

cabinet. Larger floor model cabinets have a four-sided

inverted-pyrimidal hopper that seemed a better shape to keep the feed

tube supplied with beads. I cut two triangular pieces of 1/8"

hardboard and fastened them in place with Gorilla Tape.

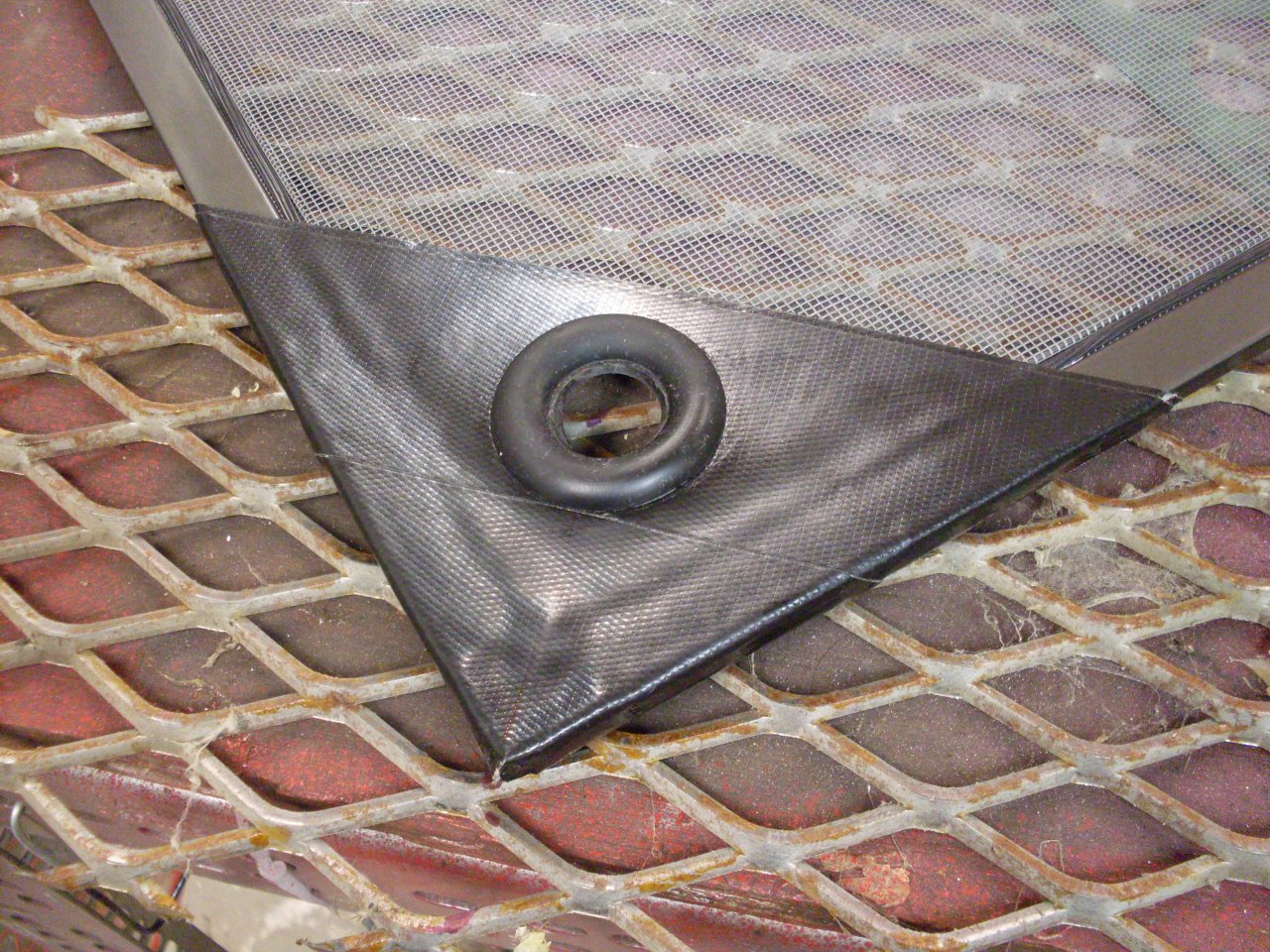

Next,

to keep the grit cleaner, I decided to put a screen under the support

mesh to keep back the larger crud. There is a layer of 1-1/4-inch

foam tape on the ledge around the perimiter of the box. On top of

that is a 3/4-inch wide foam tape. I made a framed screen out of

standard window screen materials, sized so that it fits snugly on top of

the 1-inch foam, inside the narrower tape. For the pass-through

for the media feed hose, I fortified one corner with several layers of

Gorilla Tape, then cut a hole for a rubber grommet.

Then

made a new, stouter mesh floor out of expanded steel. Edged it

with folded over Gorilla Tape to softent he sharp edges.

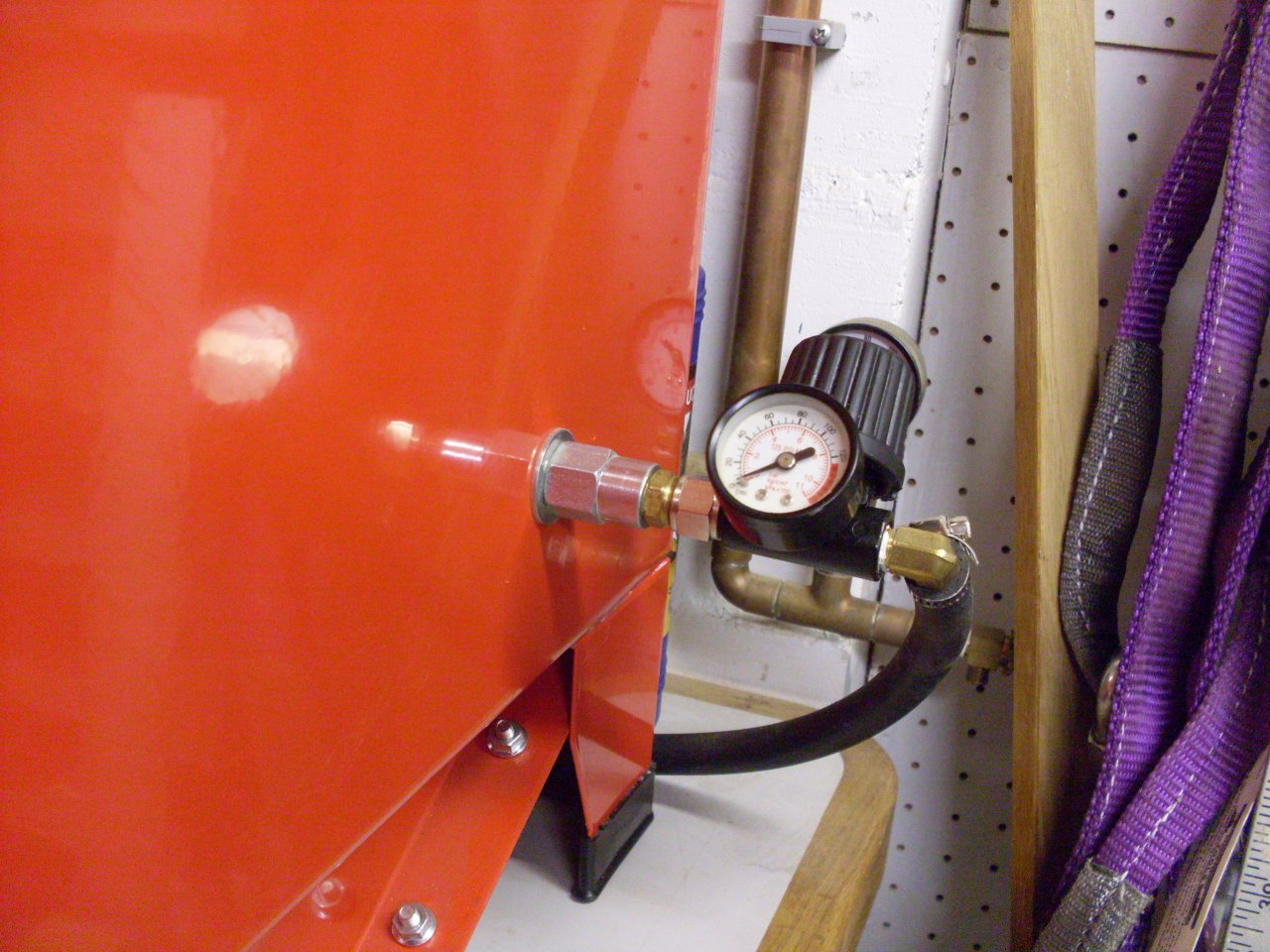

A couple of other fittings were an adaptor on the side vent to accept a vacuum hose, and a pressure regulator at the air inlet.

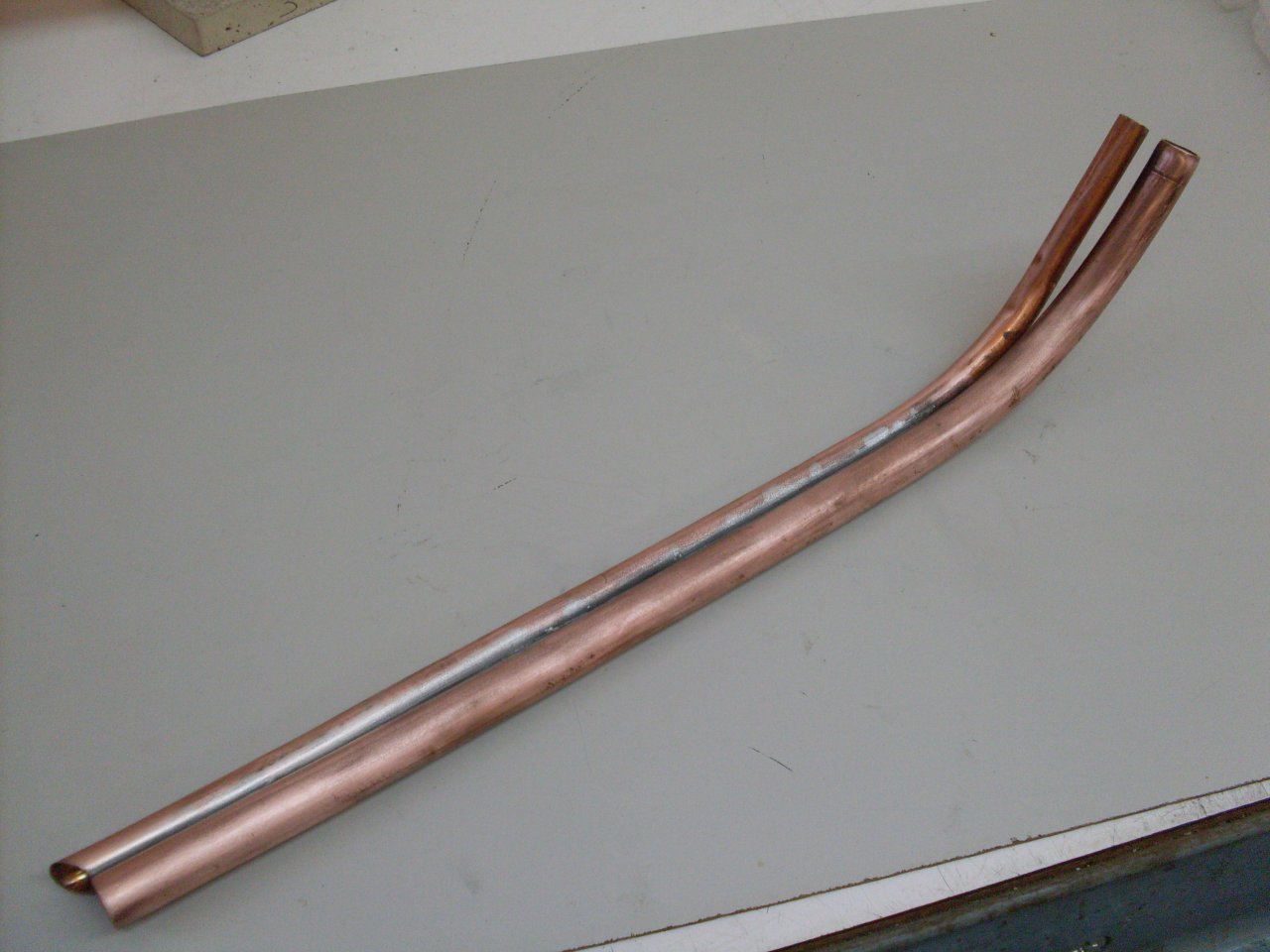

After

all of this, the cabinet was much more usable, but I had a little

trouble with the media feed being intermittent sometimes. After

looking closely at the feed tube, it occured to me that the double wall

tube was that way for a reason. The only thing I could think of

was that the annular space between the two tubes must be a vent to bring

air down, either to replace the volume of media sucked up the feed

tube, or to assist the flow of media by supplying air for an airstream

up the feed tube. This was confusing, since the configuration

before I did anything to the cabinet had the entire feed tube buried

inthe media. Possibly this explains why intermittent feed is a common

complaint for these units. My feed tube ran up the corner at the

edge of one of the new hardboard baffles, but the vent opening was often submerged under

media in the corner of the box. To test my theory, I made a new

feed tube arrangement that would ensure that the top end of the vent

tube would always be above the media. It is just two pieces of

copper tubing soldered side by side--one 1/2" for the media, and one

3/8" for the vent. The top ends pass through the grommet where

the feed hose for the gun connects to the media tube, and the vent tube

is in free air. This seems to have improved the media feed to the

gun.

The

only remaining problem was that my large shop vac is too powerful for the

exhaust. It creates enough vacuum inside the cabinet to

inflate the gloves like baloons.

The problem was that the existing filtered port on the cabinet

was really designed to be an exhaust for the blasting air. With a

lot of air being pulled by the shop vac, the port becomes an inlet, and

it's not big enough to supply air for the vacuum, especially with a

filter on it, so the pressure in the cabinet drops drastically.

While low pressure in the cabinet is good for keeping the door

seal tight, I had too much of a good thing.

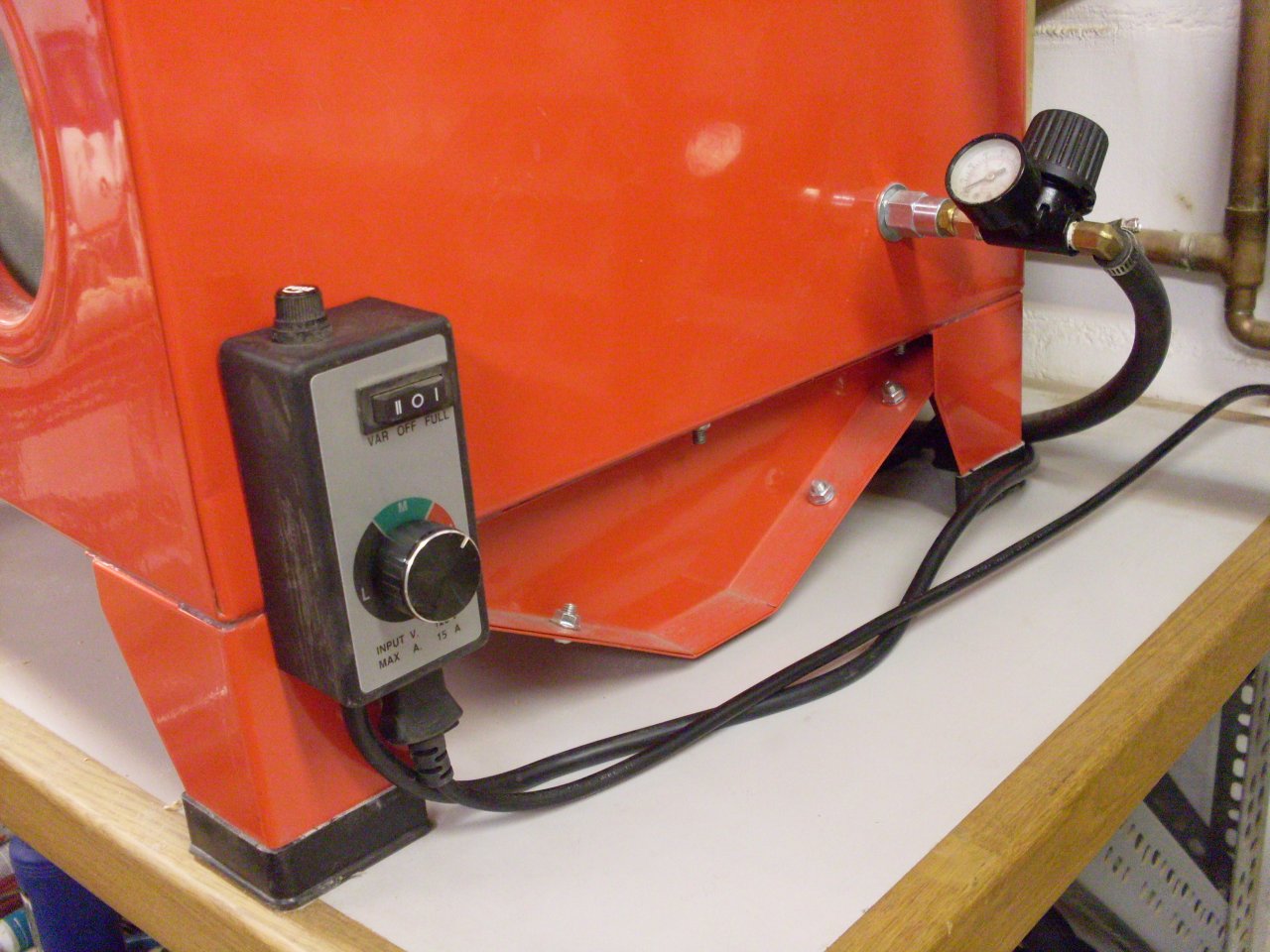

Thinking that my

main shop vac was overkill anyway, I bought a small vac to dedicate to

the cabinet, and also put a speed control on it so I could control the

process. With this setup, I can keep the cabinet clear while

maintaining a reasonable negative pressure in the cabinet.

Right

now there is no good way for me to exhaust the vac to the outside, so

I'm looking into what filter media I can put in the vac.

Comments to: elhollin1@yahoo.com